Method and device for ceramic curved surface screen printing

A technology of screen printing and screen printing, applied in printing devices, screen printing machines, printing and other directions, can solve the problems of ceramic curved screen printing machines that have not yet been found, and achieve easy maintenance, high accuracy and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] First, in accordance with the performance indicators to be achieved by the printing machine, design and implementation plans are formulated for mechanical and electrical components, process routes, materials and production methods.

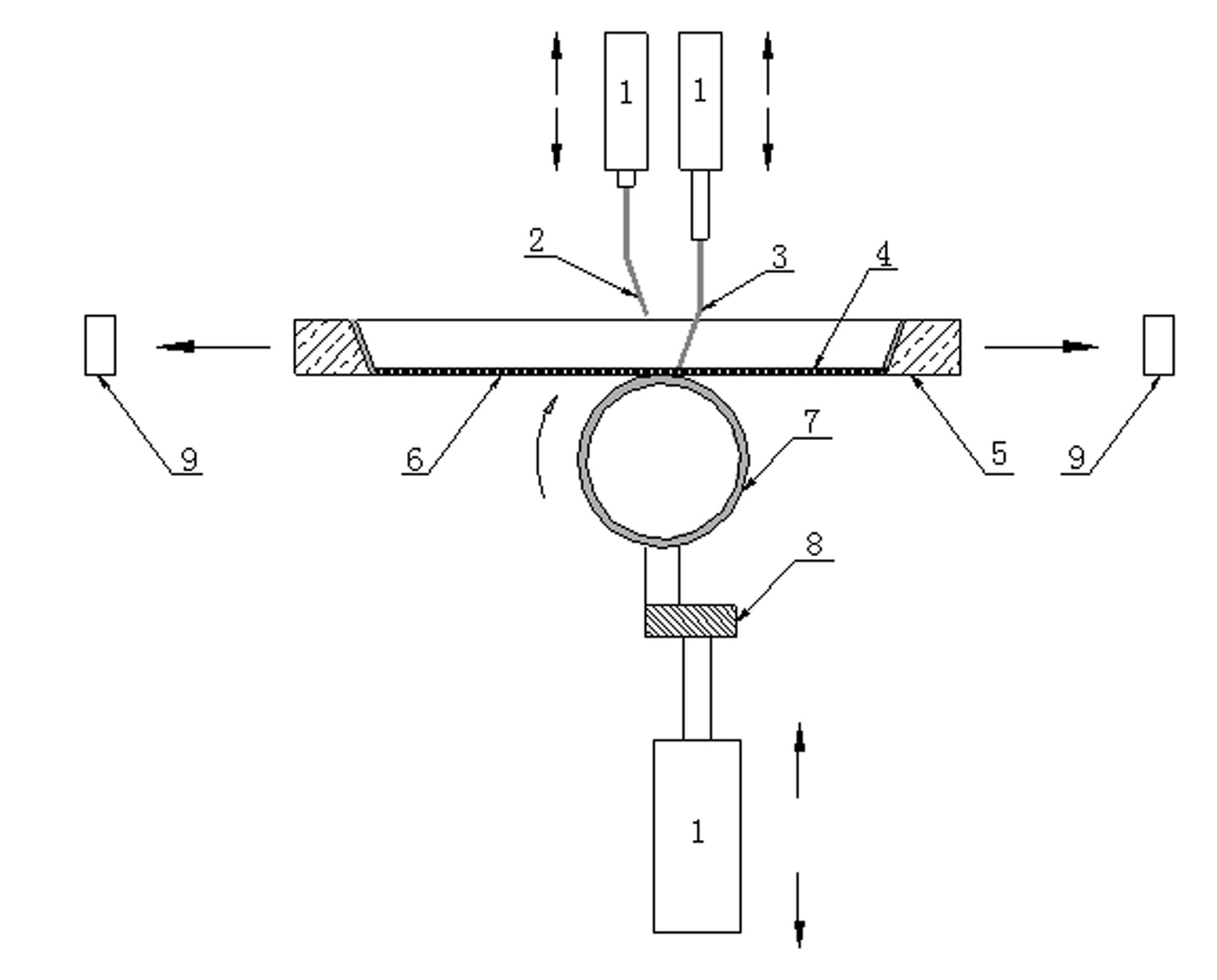

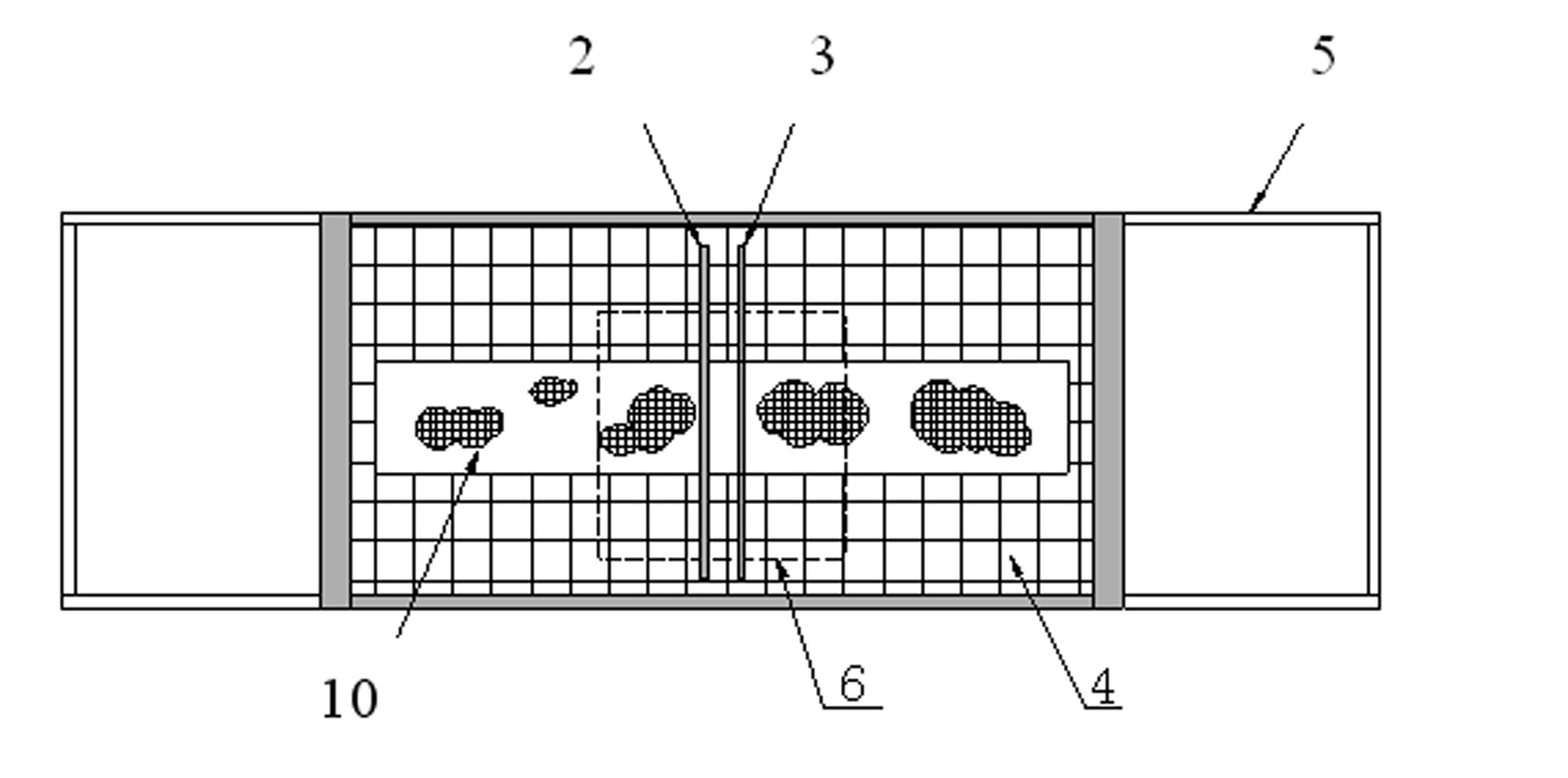

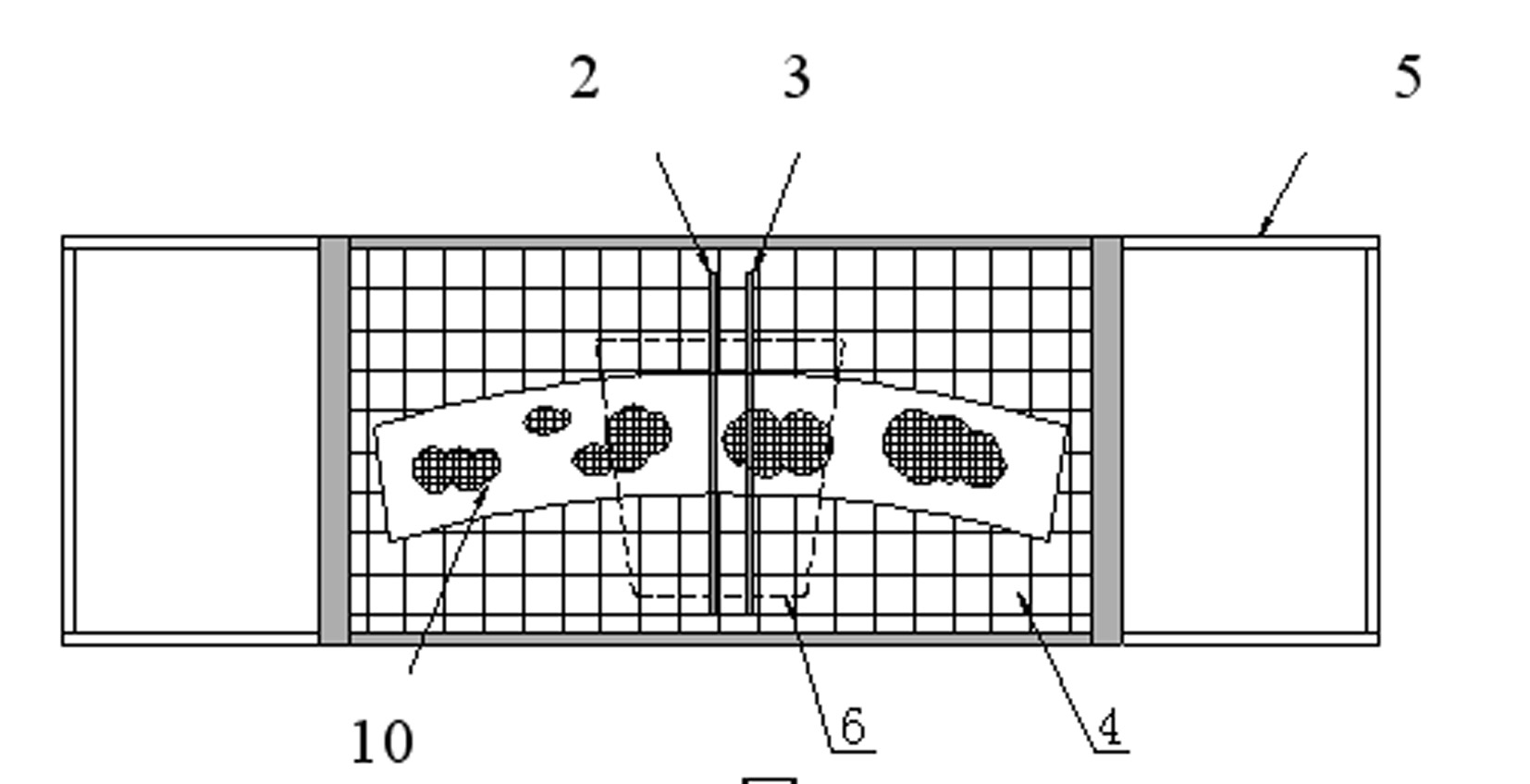

[0018] The working mechanism of the printing machine is: when the screen frame moves horizontally, the squeegee descends to contact the screen printing template, and the ink penetrates the graphic mesh under the pressure of the stationary squeegee. At the same time, the substrate mold support rises to contact the bottom of the screen frame, and the substrate rotates in place (horizontally stationary) driven by the movement of the screen frame, so that the ink passing through the graphic mesh is transferred to the surface of the substrate . The curved surface of the ceramic body of the substrate is the outer wall of a cylinder, a cone and an arc cylinder.

[0019] The working process of the printing machine is: each printing cycle is divided int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com