Non-contact type level gage mounting method

An installation method and non-contact technology, applied in the direction of measuring devices, lubrication indicating devices, liquid/fluid solid measurement, etc., can solve the problems affecting the normal progress of trial production, affecting the production progress, and unfavorable physical and mental health and safety of construction personnel, etc. To achieve the effect of ensuring the success rate, convenient material collection, and saving the installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] A specific embodiment of the present invention will be further described in detail below with reference to the accompanying drawings.

[0023] As shown in the figure, a non-contact level gauge installation method includes the following steps:

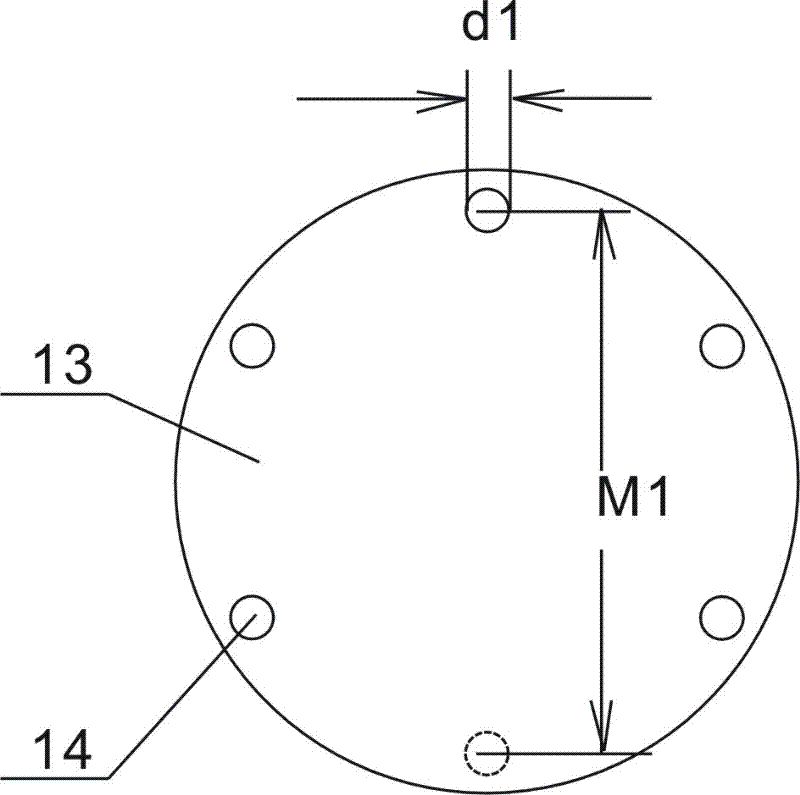

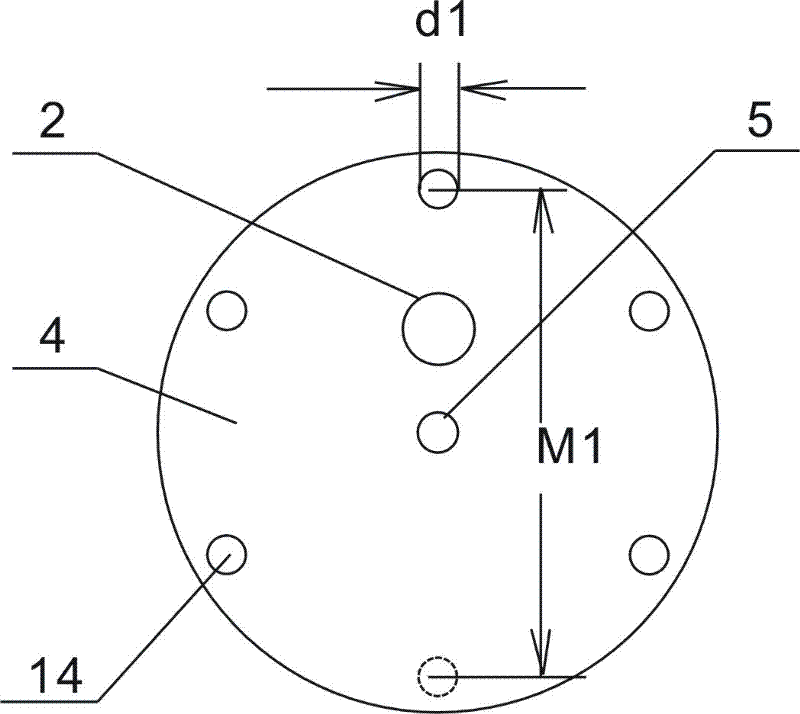

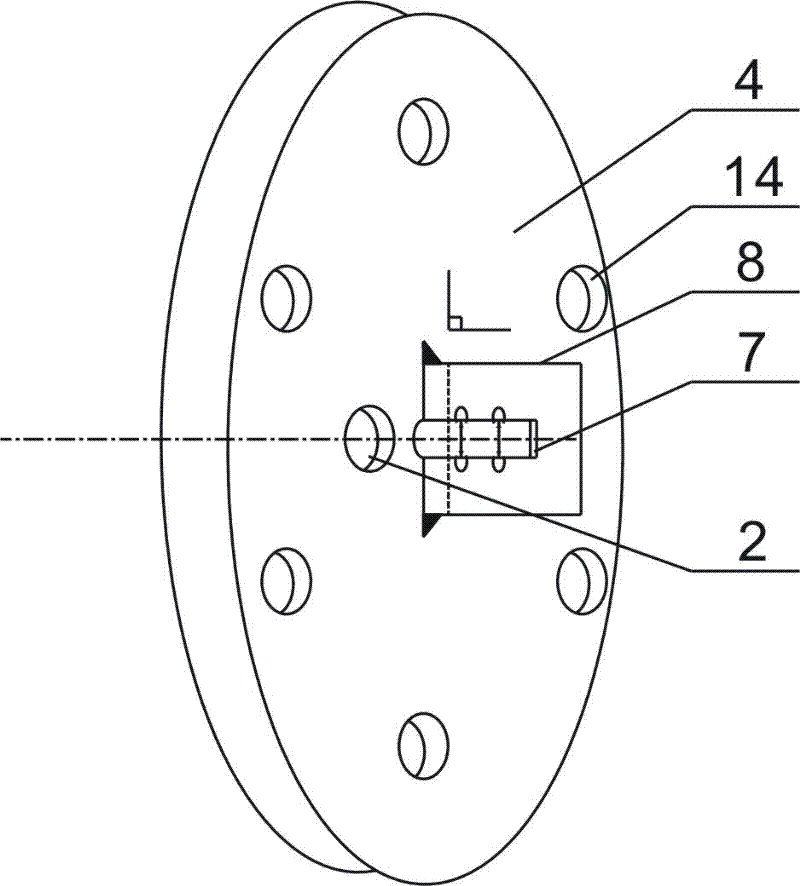

[0024] 1) Making the alignment device: the alignment device includes the pre-installed flange 4 and the laser source 7. First, measure the diameter of the mounting flange 13 of the level gauge and the hole diameter d1 of the mounting screw hole 14 and the hole distance M1 (such as Figure 1a As shown), according to this, use the ordinary steel plate at the construction site to cut the pre-installation flange 4, and ensure that the diameter of the pre-installation flange 4, the hole diameter and the hole distance of the mounting screw hole 14 and the corresponding level gauge are installed The size of flange 13 is the same (such as Figure 1b Shown). Open a laser source installation hole 5 and an observation hole 2 at the axis of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com