Visual evaluation device and method for motion state of machine tool group component

A motion state and component technology, applied in metal processing mechanical parts, measuring/indicating equipment, metal processing equipment, etc., can solve the problems of inconvenient adjustment of mechanical state, affecting the processing effect of the whole machine, poor operability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

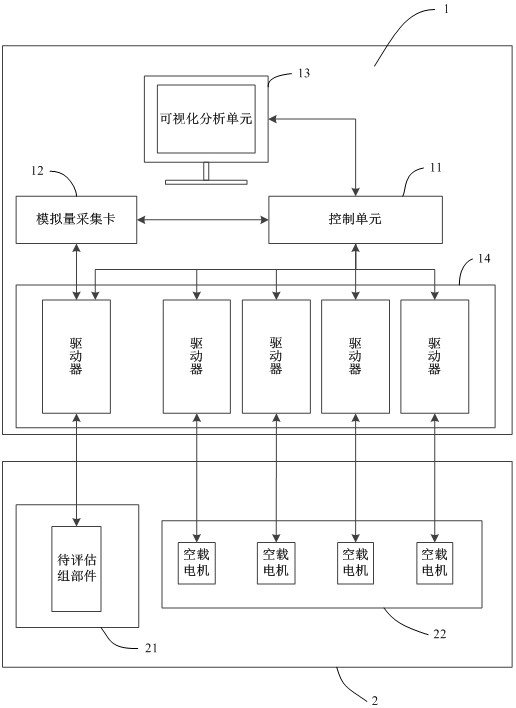

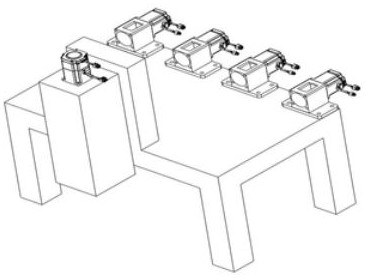

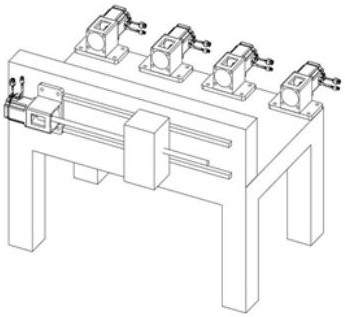

[0028] like figure 1 As shown, a visual evaluation device for the motion state of machine tool components of the present invention is composed of an electric control platform 1 and a component installation platform 2. The electric control platform 1 includes a control unit 11, an analog acquisition card 12, and a visual analysis unit 13 And the driver unit 14;

[0029] The component installation unit 21 is used to install the components to be evaluated, and the no-load motor installation unit 22 is used to install the no-load driving motors of other moving components of the machine tool except the components to be evaluated. The driver unit 14 is provided with the same number of drivers as the number of motion axes of the machine tool, which are respectively connected to the drive motors of the components to be evaluated and the no-l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com