Detection and evaluation method of crack condition on external insulating layer of thin-plastered outer wall

A technology for external wall thermal insulation and thin plastering, applied in the direction of material resistance, etc., can solve the problems of inability to measure the depth of cracks, waste of energy, and little effect, and achieve the effect of simple and convenient testing process, guaranteeing accuracy, and facilitating judgment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

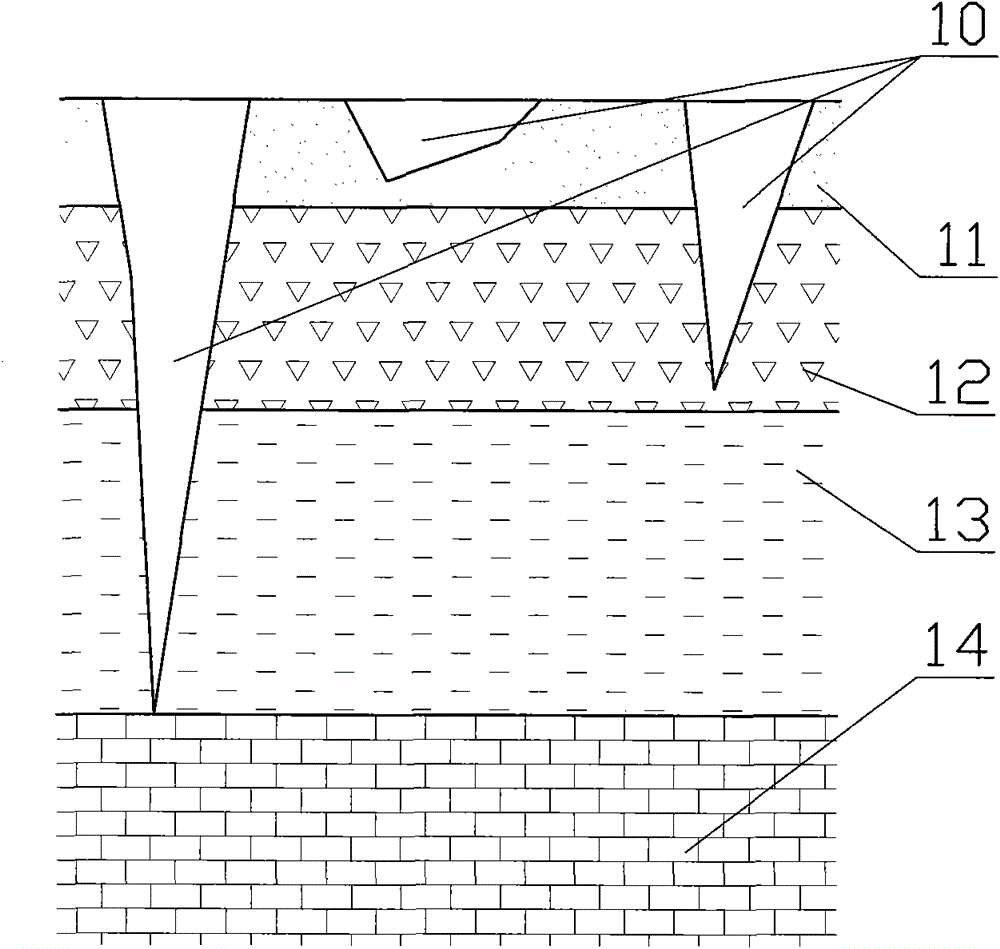

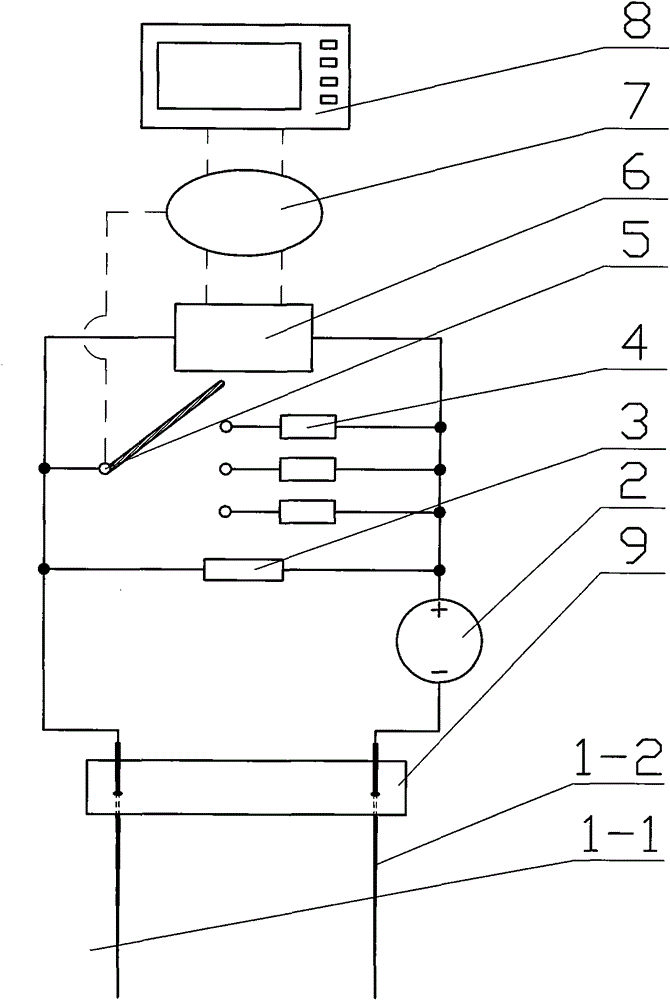

[0049] The present invention will be further described below in conjunction with accompanying drawing.

[0050] Thin plastered external wall insulation crack resistance tester includes first probe 1-1, second probe 1-2, voltage stabilized power supply 2, overcurrent protection resistor 3, gear resistance 4, selection switch 5, A / D converter 6, central controller 7 and LCD display 8, the first probe 1-1, the second probe 1-2 are two metal needles with a diameter of 0.05mm and a length of 50mm, and the two probes 1-1, 1 -2 is fixed on the bracket 9 with a distance of 50mm, and its material is high-strength, high-toughness, low-resistivity alloy steel. The lead from pin 1-1 is connected in series with the variable resistor group and connected to the positive pole of the stabilized power supply 2. The variable resistor group consists of an overcurrent protection resistor 3 and three gear resistors 4 with different resistance values with a selection switch 5 connected in paralle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com