Substrate processing equipment and ejector pin lifting device

A technology of substrate processing equipment and lifting devices, applied in the direction of transportation and packaging, conveyor objects, electrical components, etc., can solve problems such as crystal slipping, small adjustment range, and complicated leveling, and reduce the possibility of positional deviation , Improve safety and reliability, good shock absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The core of the present invention is to provide a thimble lifting device for substrate processing equipment, which can effectively prevent the crystal from slipping off the thimble when it is in contact with the thimble, thus having high safety and reliability. Another core of the present invention is to provide a substrate processing equipment including the above ejector pin lifting device.

[0029] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

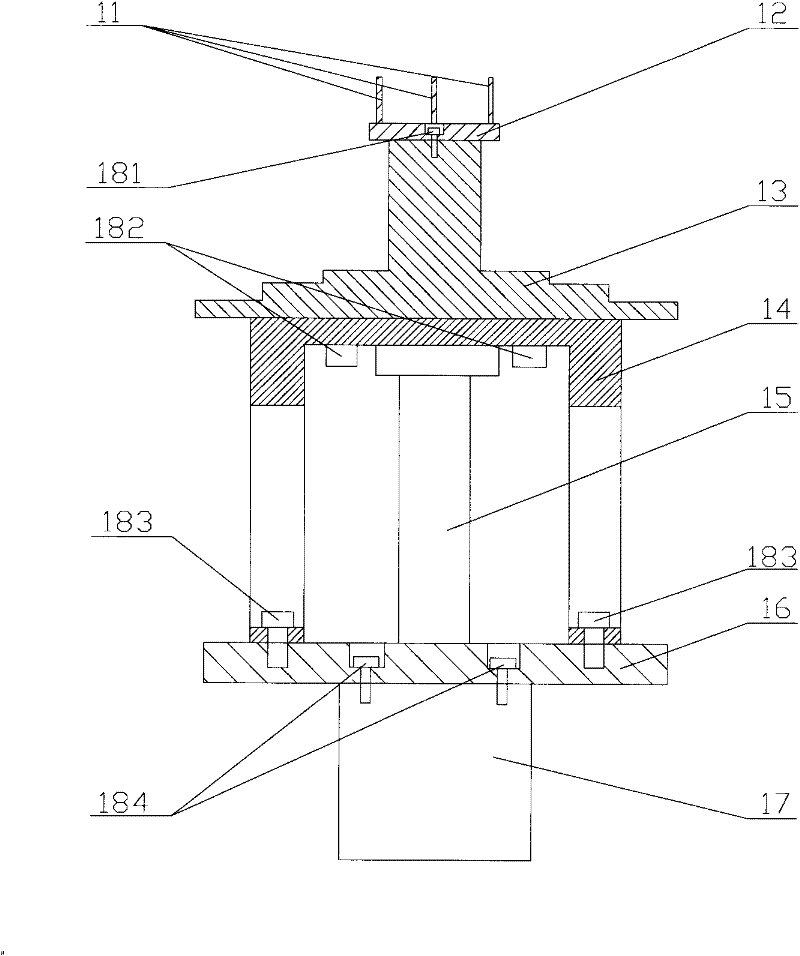

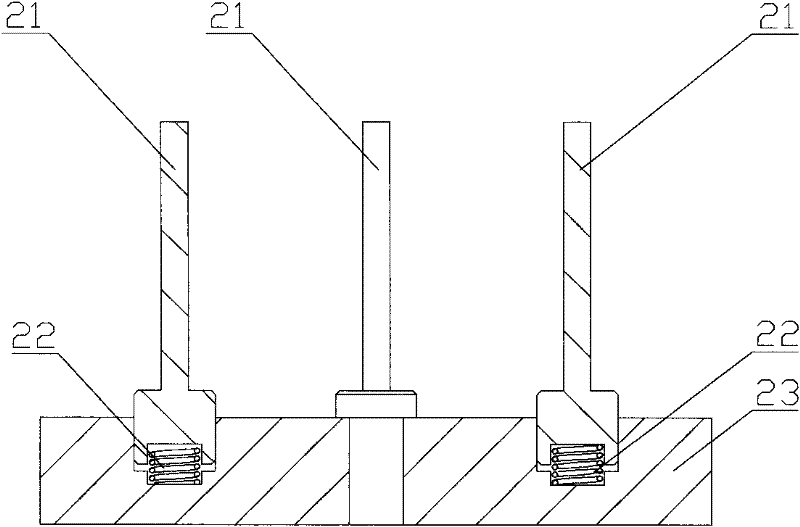

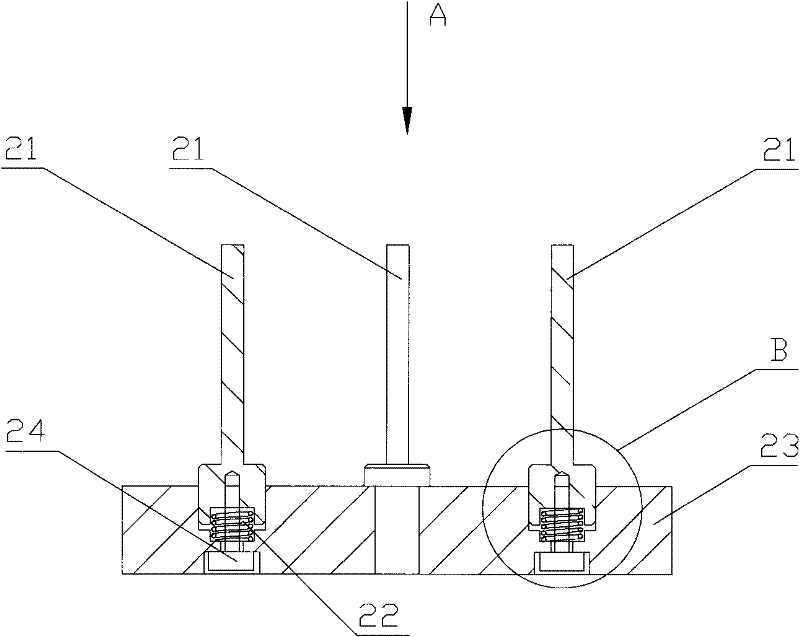

[0030] Please refer to figure 2 , figure 2 It is a structural schematic diagram of a specific embodiment of the thimble lifting device provided by the present invention.

[0031] In a specific embodiment, the thimble lifting device provided by the present invention includes a cylinder located at the lower part of the device, the cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com