Electron accelerator

A technology of accelerators and high-voltage electrodes, used in DC voltage accelerators, electrical components, accelerators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

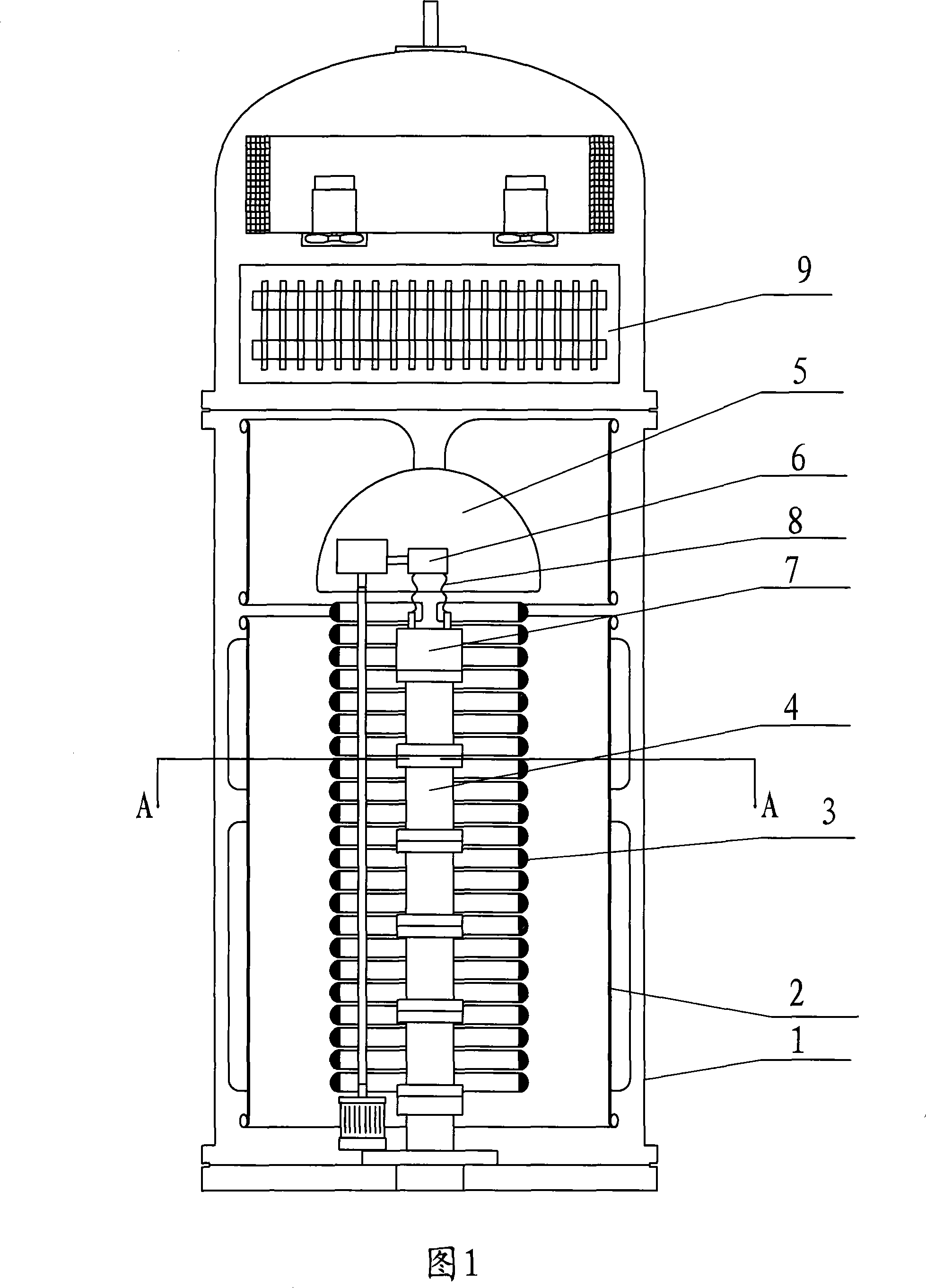

[0019] Such as figure 1 The shown accelerator includes a steel cylinder 1, a high-frequency transformer 9 arranged above the steel cylinder 1, a plurality of semicircular equalizing rings 3 arranged inside the steel cylinder 1, and a high-voltage electrode 5 arranged above the equalizing ring 3 , two high-frequency electrodes 2 arranged on the outside of the equalizing ring 3 and the high-voltage electrode 5, an electron gun 7 with a filament 8 for generating and exciting electrons, a filament transformer 6 for adjusting the voltage of the filament 8, and an electron gun 7 arranged on the Accelerator tube 4 below the vacuum.

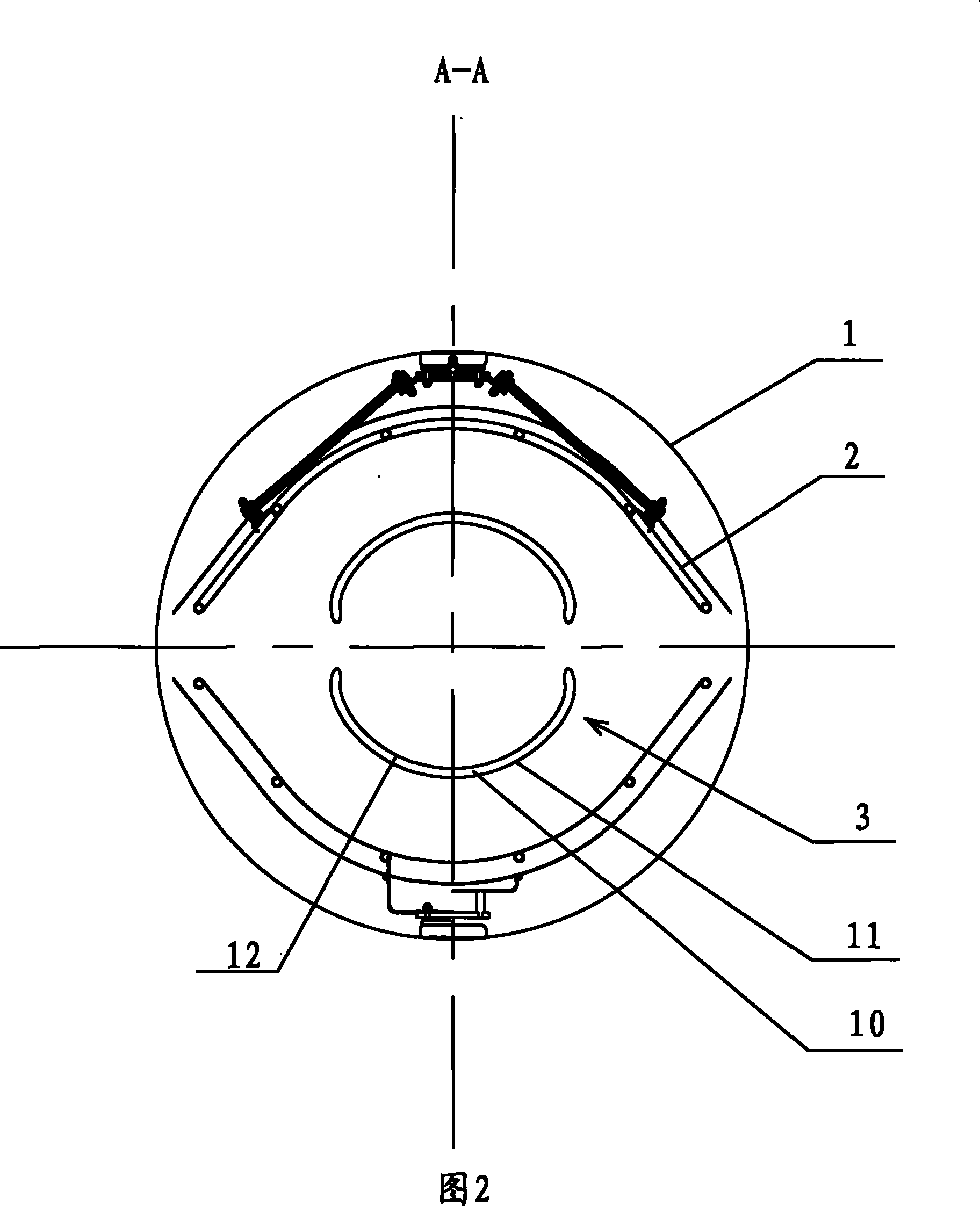

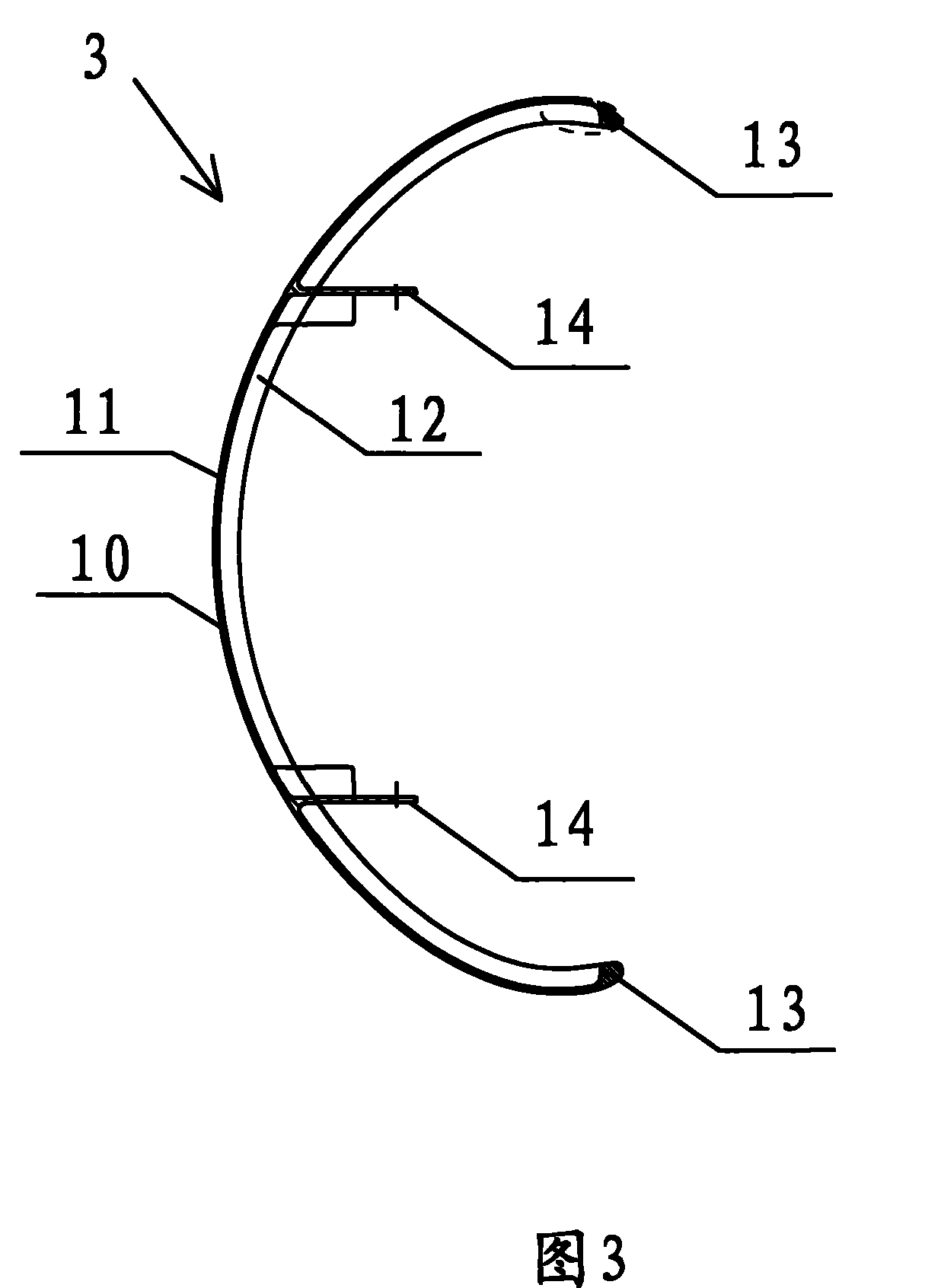

[0020] A plurality of semicircular pressure equalizing rings 3 are symmetrically arranged in two rows along the axis of the steel cylinder 1 with their openings facing each other. Such as figure 2 As shown, the equalizing ring 3 is arranged inside the high-frequency electrode 2 , and the steel drum 1 of the accelerator is surrounded outside the high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com