A forged steel globe valve with high cushioning

A buffering, globe valve technology, applied in the field of forged steel globe valves, can solve the problems of poor sealing reliability, large fluid resistance, and valve stem deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

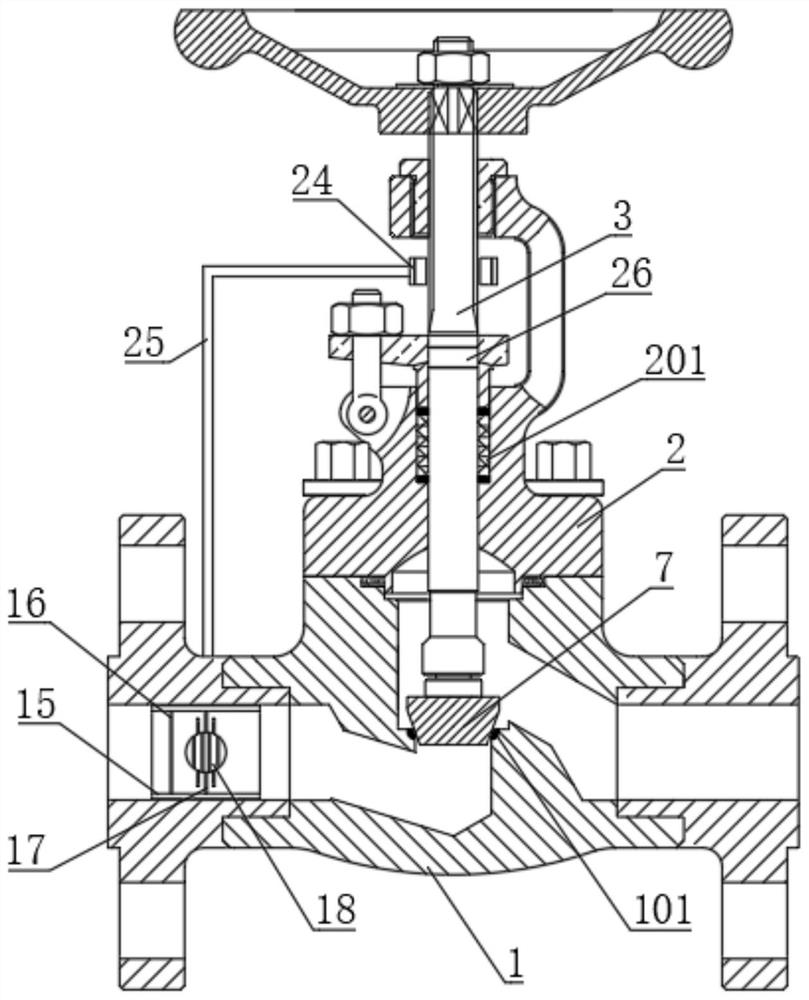

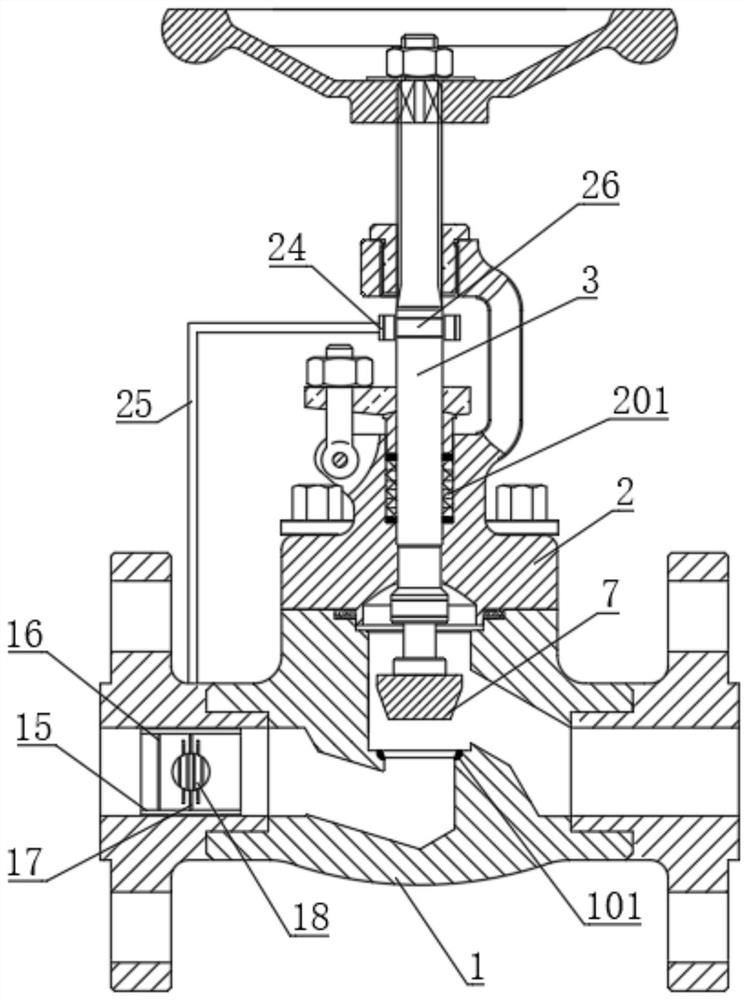

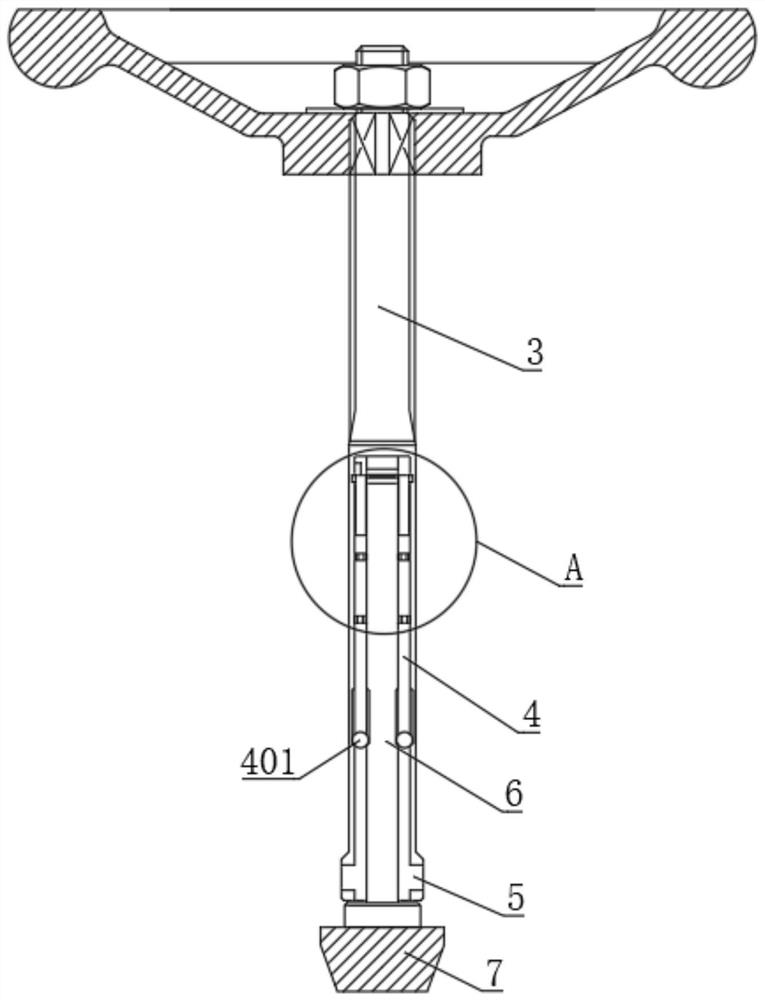

[0042] see Figure 1-5 , a forged steel globe valve with high cushioning, comprising a valve body 1, the upper end of the valve body 1 is fixedly connected with a valve cover 2, the upper end of the valve cover 2 is rotatably connected with a valve stem 3, and the lower end of the valve stem 3 penetrates the valve cover 2 Extending to the inner cavity of the valve body 1 , a hydraulic cavity 4 is excavated inside the valve stem 3 , a first through hole 5 is excavated on the outer circumferential surface of the valve stem 3 , and the space between the first through hole 5 and the hydraulic cavity 4 is Connected, the inner cavity of the hydraulic cavity 4 is embedded with a connecting rod 6, the lower end of the connecting rod 6 is fixedly connected with the valve core 7, the inner top of the hydraulic cavity 4 is fixedly connected with a first magnet block 8, and the connecting rod 6 is fixedly connected. The upper end of the hydraulic cavity 4 is fixedly connected with a secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com