Process for the purification of an aqueous stream coming from the fischer-tropsch reaction

A liquid and reactive technology, applied in chemical instruments and methods, preparation of liquid hydrocarbon mixtures, water/sludge/sewage treatment, etc., can solve the problem that organic compounds cannot be completely discharged and/or regenerated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

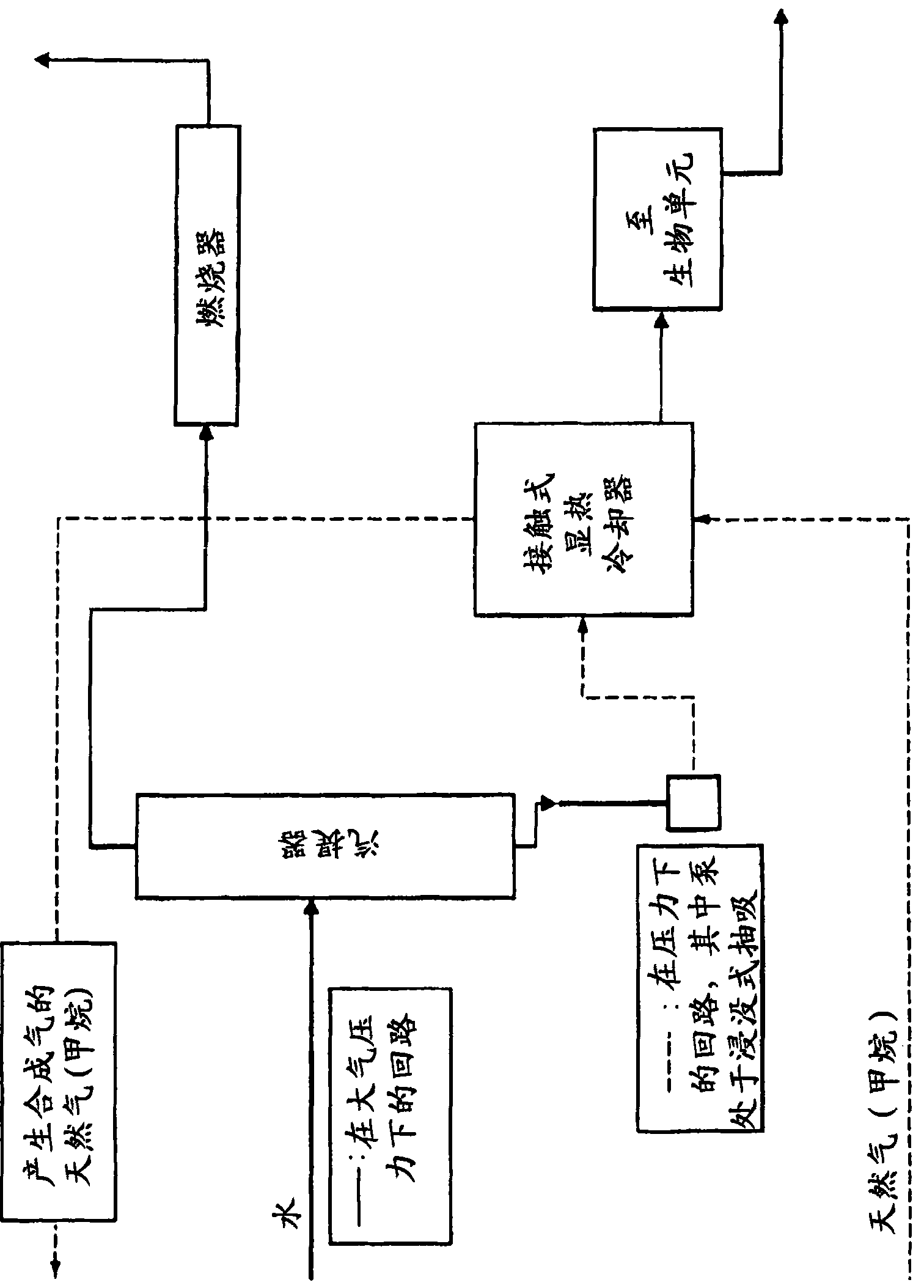

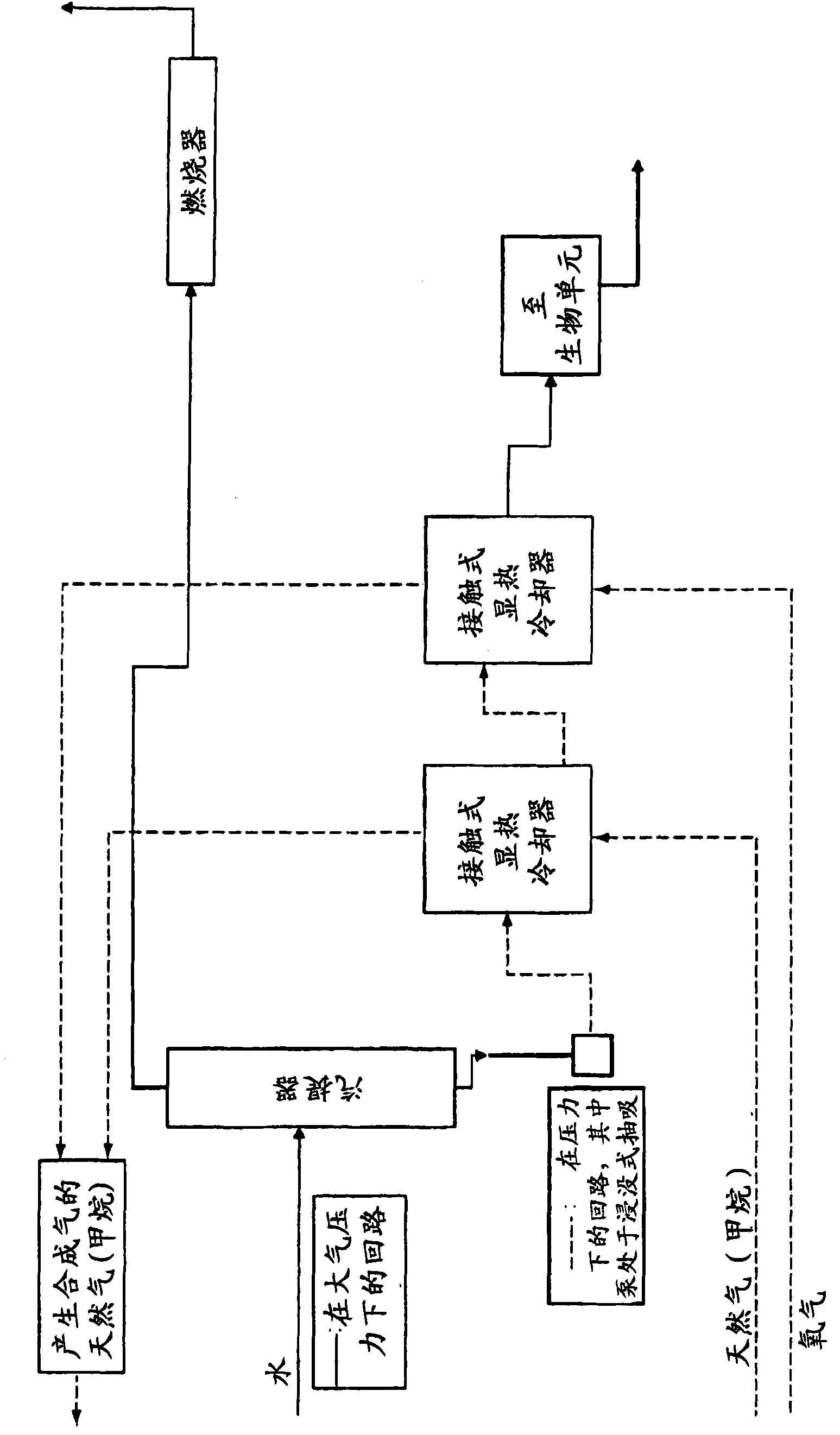

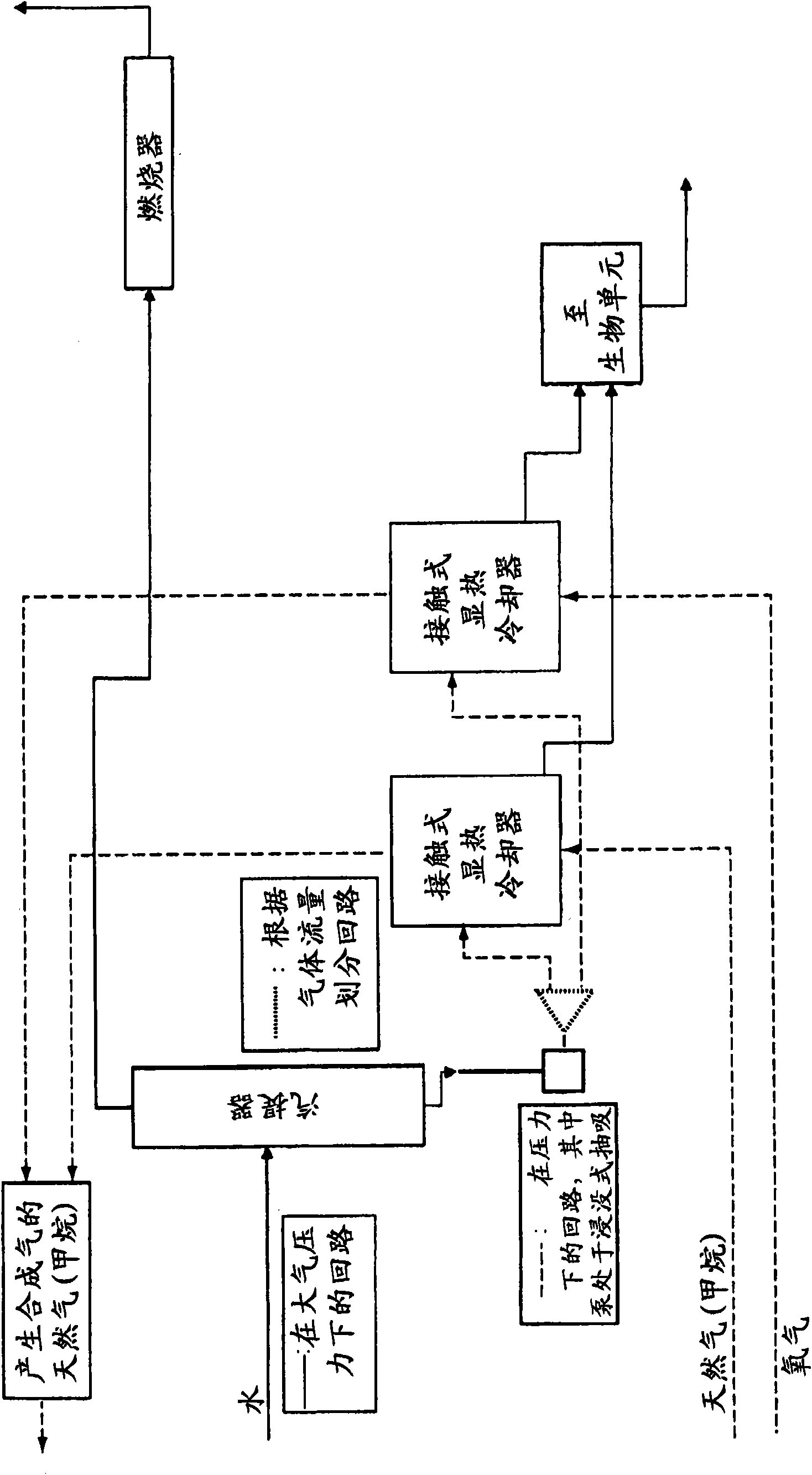

Method used

Image

Examples

Embodiment 1

[0062] A pump set with impellers submerged in a well of less than 7 m in height relative to the bottom of the stripping column receives a liquid stream having a temperature equal to about 290 kg / h at a temperature equal to 101.4° C. for a pressure corresponding to 1030 hPa flow. The pump brings the water under pressure back to the 45 bar value it assumes at the inlet of the sensitive contact heat exchanger. The methane gas stream is delivered at a flow rate of less than 325 kg / h, a temperature of about 25°C and a pressure equal to the inlet pressure of water.

[0063] The heat exchanger is manufactured to achieve a performance equal to 5 theoretical thermodynamic steps, in fact, an inlet temperature of pressurized water equal to 105°C corresponds to an outlet temperature equal to 40°C, remembering that there is no insulation.

[0064] Regardless of the fact that the flow rate being added to the outgoing gas stream has been reduced by 7 kg / h, the data representing the composit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com