Ball mill

A ball mill and cylinder technology, applied in the field of ball mills with noise reduction structure, can solve the problems of multiple costs, bad working environment, large land area, etc., and achieve the goals of reducing cost and occupied area, improving operating environment, and reducing operating noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

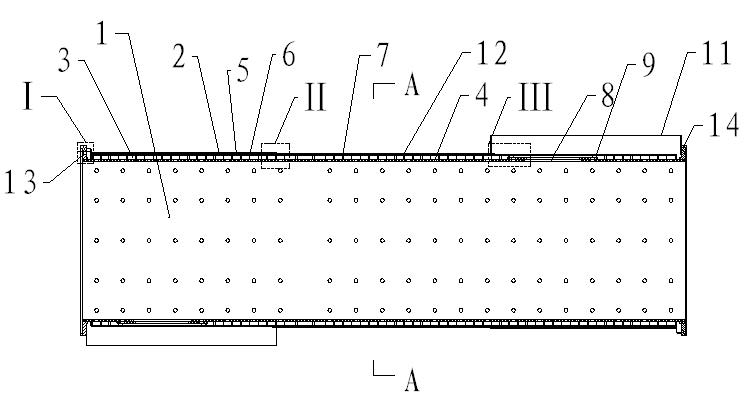

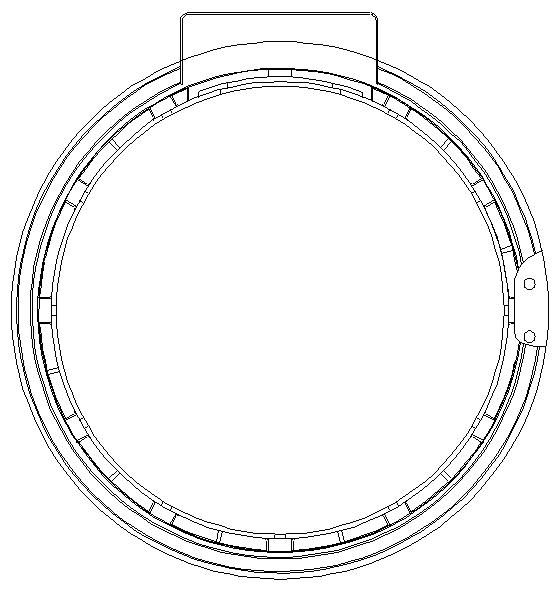

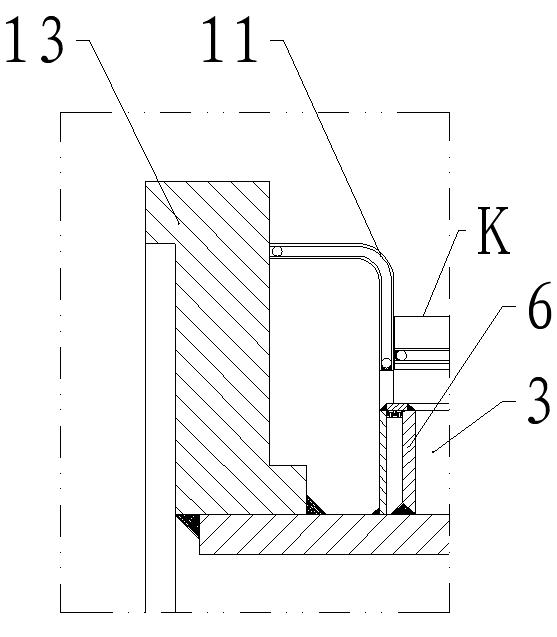

[0032] Such as Figure 1 to Figure 11As shown, the cylinder 1 of the ball mill is provided with an annular support wall 6 corresponding to the position of each bolt hole 4, and a sound insulation cover 2 matching the contour of the cylinder’s rotating surface is provided with a plurality of ring support walls 6. Each hole wall is connected with each annular support wall 6, thereby forming a vacuumable sound insulation chamber 3 between the sound insulation cover 2 and the cylinder 1, and a support column 7 is arranged between the annular support walls 6, and on the support column 7 The connecting liner 5 supports the soundproof cover 2; on the cylinder 1, near the feed end 13 and the discharge end 14, there are respectively upper and lower manholes 8 protruding from the rotating surface of the cylinder, corresponding to the manholes 8 Two manhole covers 11 are arranged at the positions, and the manhole covers 11 are slidably connected to the sound insulation cover 2, and an an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com