Sealed water-ring thermal cutting machine set

A sealed and eager cutting machine technology, which is applied in metal processing and other directions, can solve the problems of difficult cooling, sharp drop in template temperature, water leakage, etc., and achieve the effects of increasing air drying and dehydration, ensuring granulation quality, and accelerating cooling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

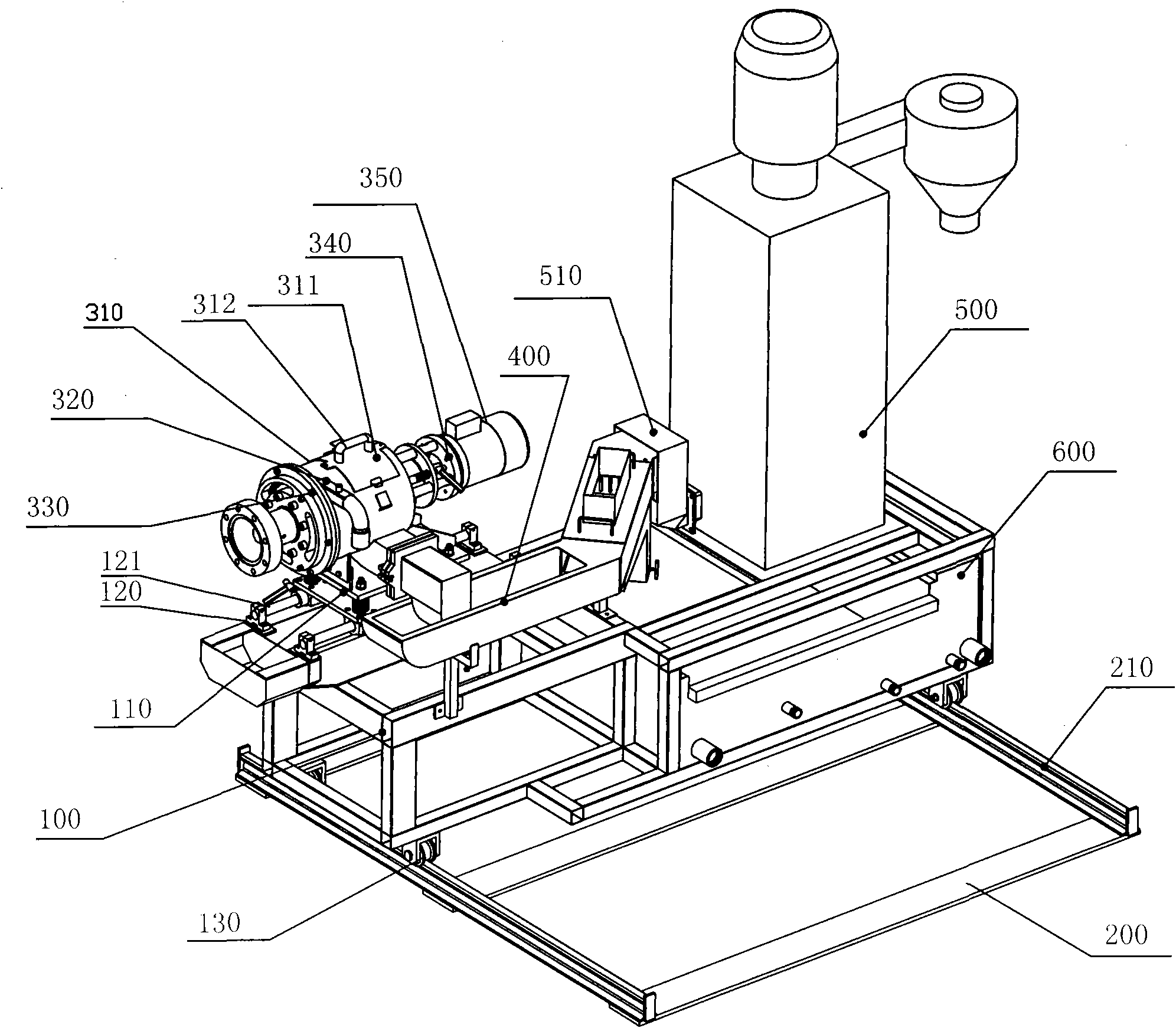

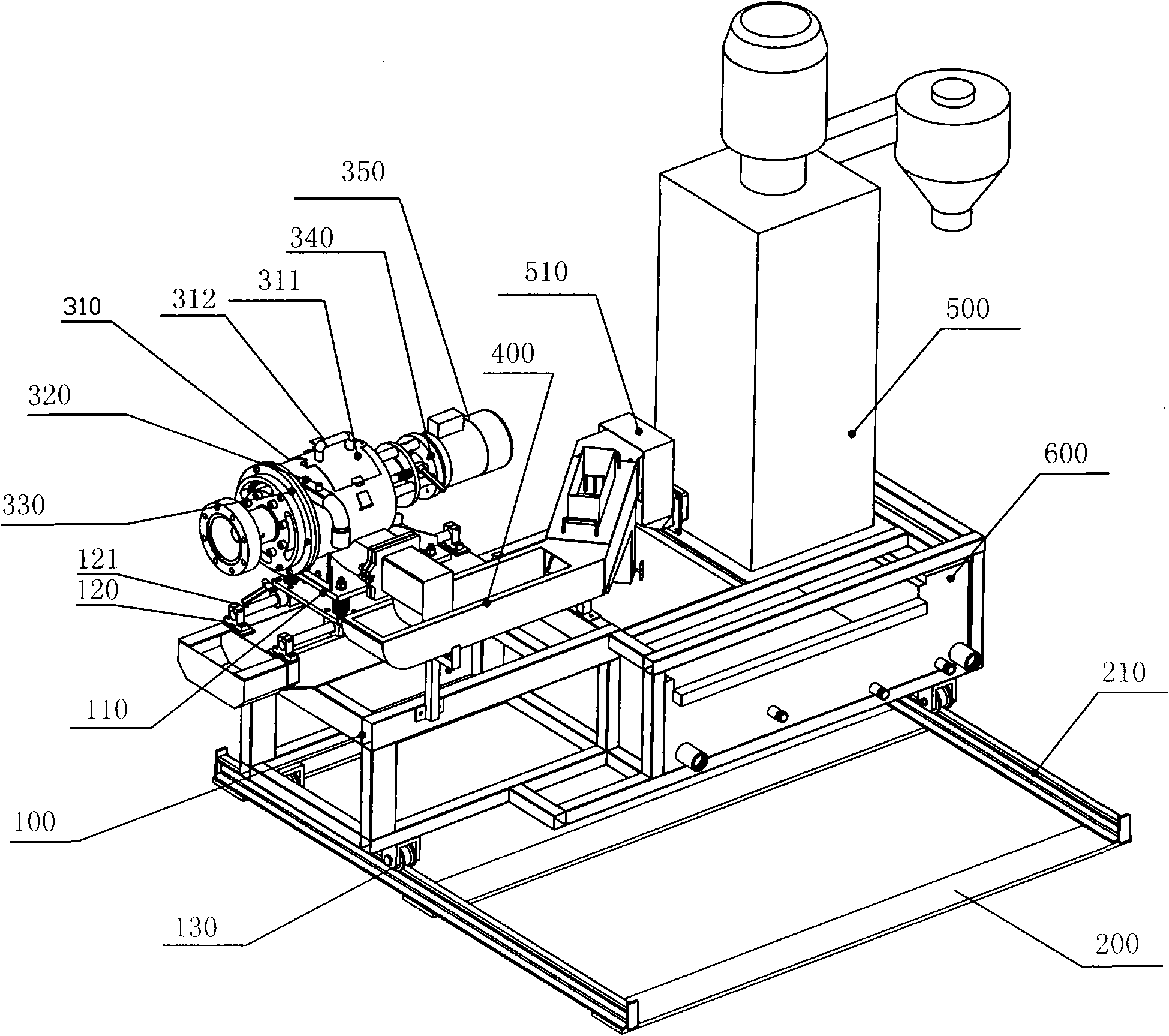

[0015] see figure 1 , the present embodiment provides a sealed water ring eager cutting unit that is convenient for the processing and manufacture of elastic materials, including a frame and an eager cutting machine on the mounting frame, a diversion groove 400, and a centrifugal dehydrator 500; the eager cutting machine includes a water ring cover Body 310, discharge mold 330, cutter group 320, power group (not shown in the figure) and motor 350. The water ring cover 310 is a cylinder, and cooling water circulates in its inner wall. A discharge mold 330 is installed at the front end of the water ring cover 310. The discharge mold 330 is provided with a die and a rotary knife for cutting and extruding. out of the material. A cutter group 320 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com