Feeding device in waste plastic cutting and compacting extrusion granulator

A technology of feeding device and waste plastic, applied in the field of feeding device, can solve the problems of low output, unstable feeding, high energy consumption, etc. The effect of increasing production and high economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The feeding device in the waste plastic cutting and compacting extrusion granulator of the present invention will be further described in detail below in conjunction with the accompanying drawings.

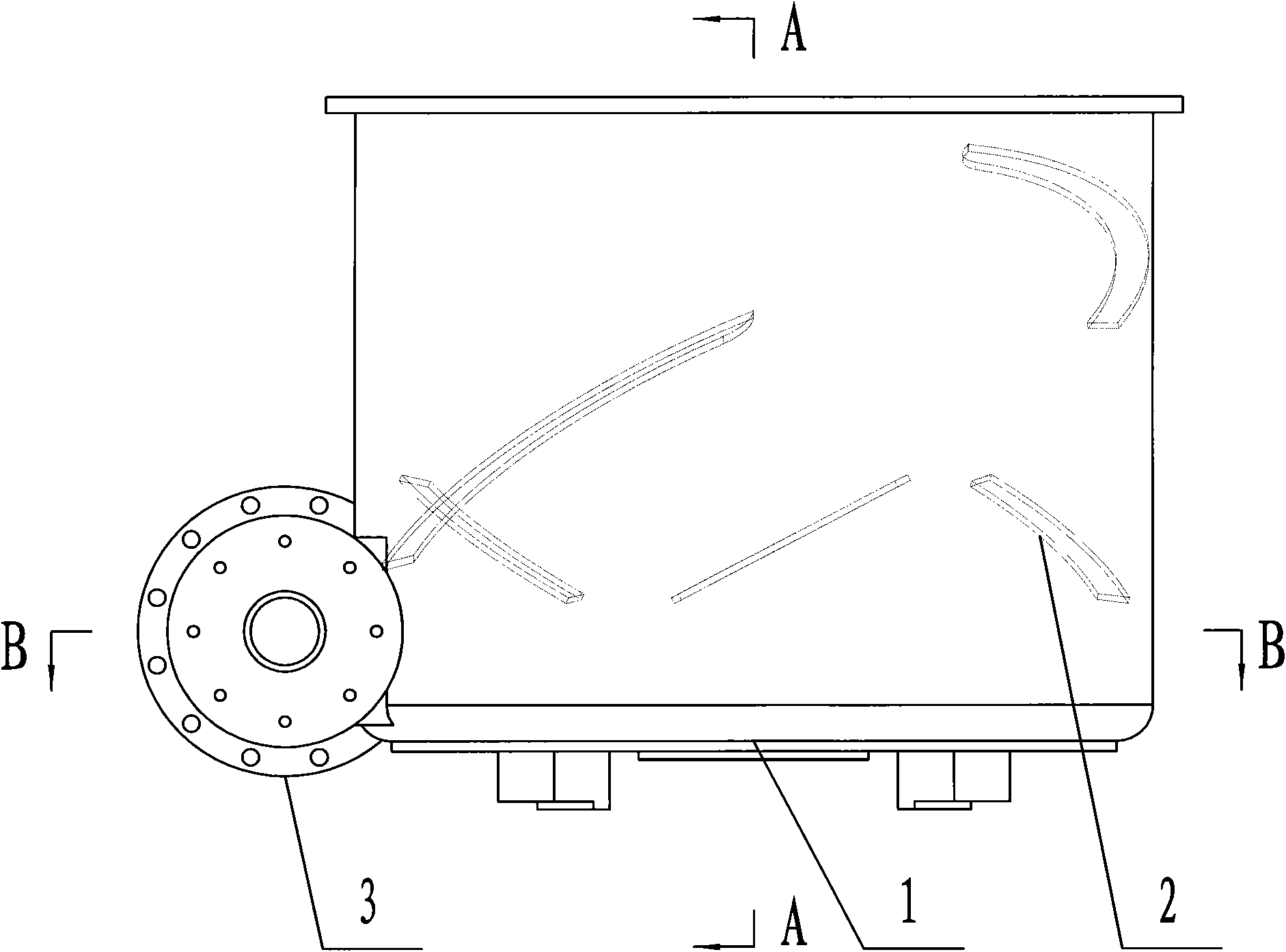

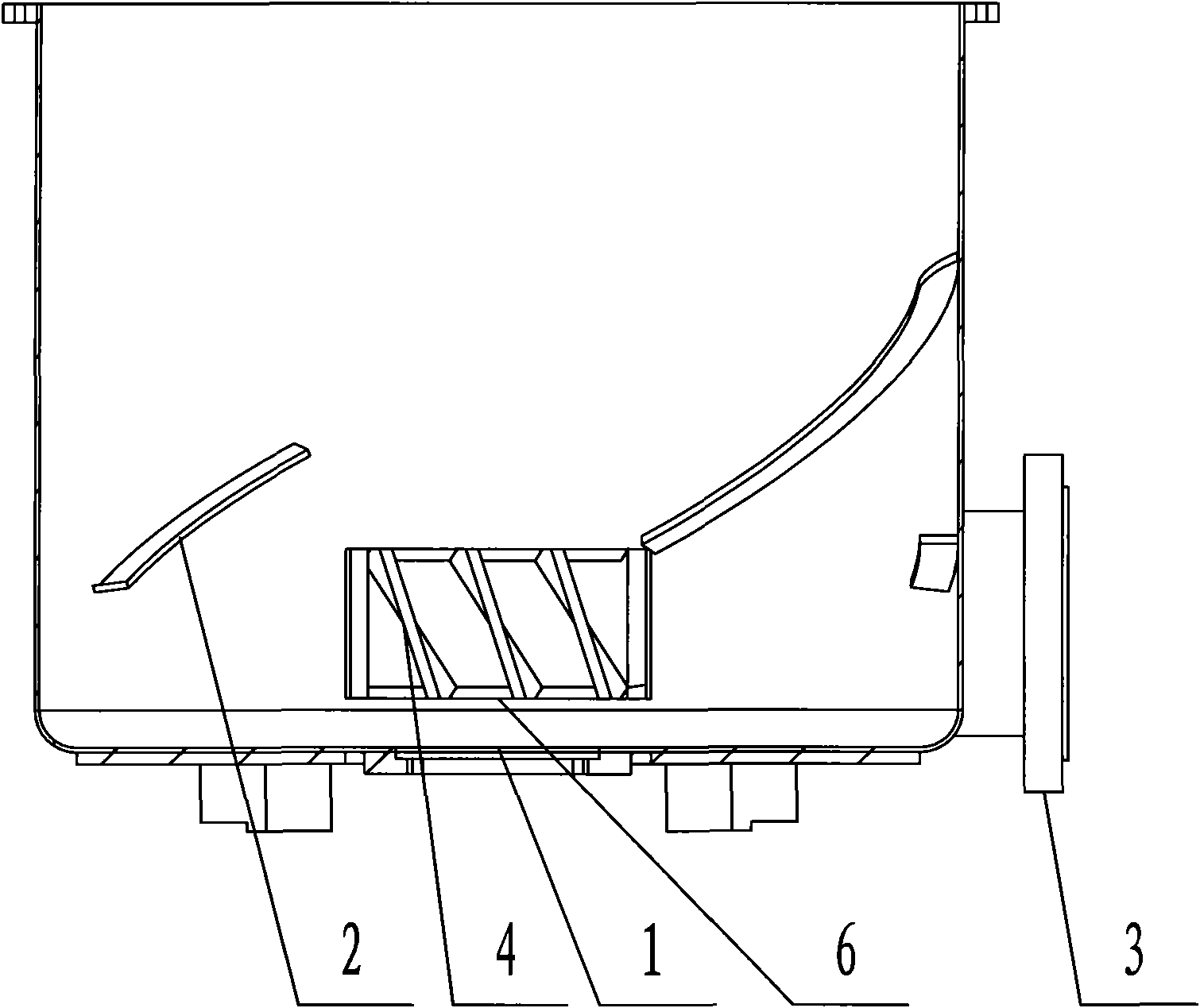

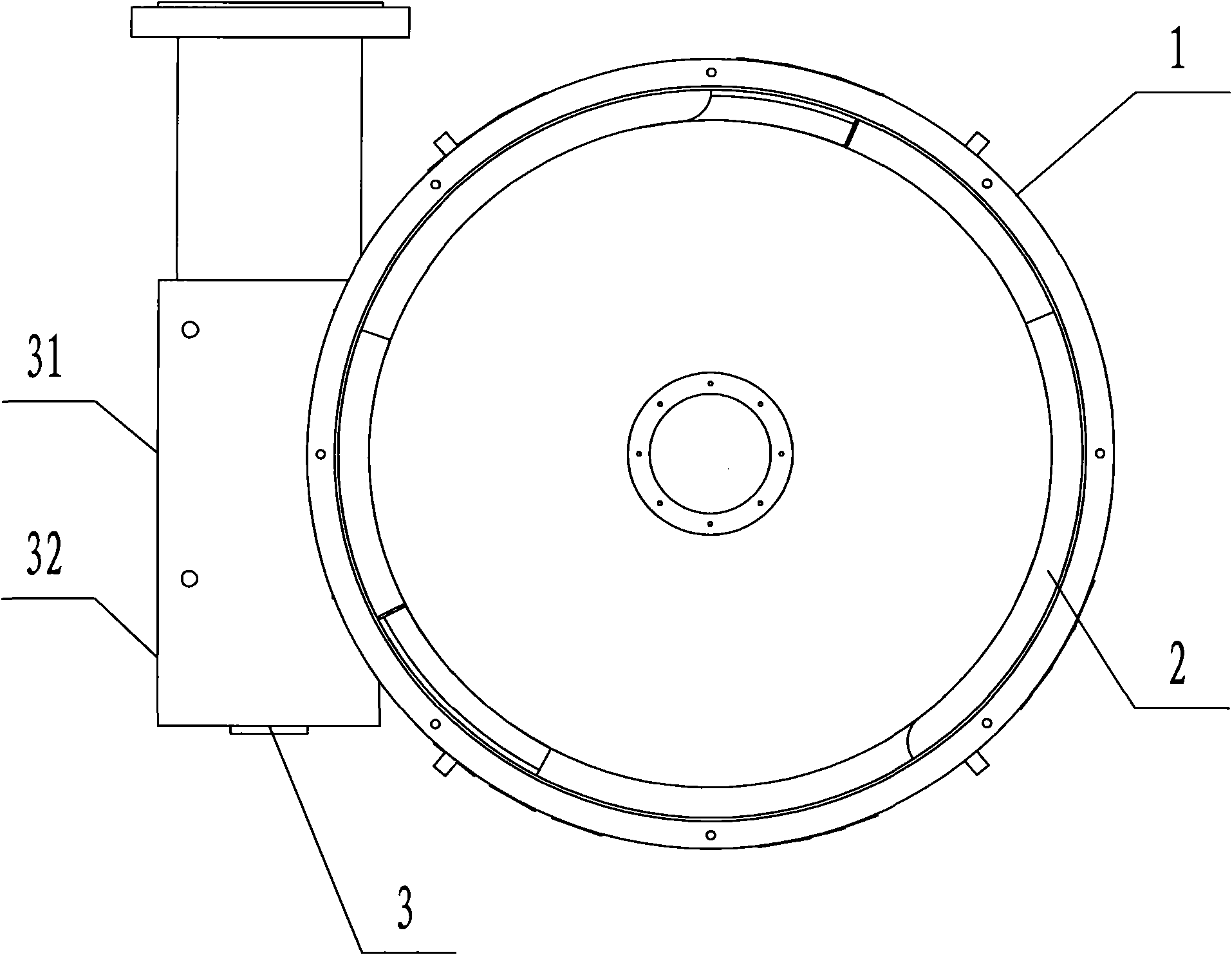

[0015] Such as figure 1 As shown, the feeding device in the waste plastics cutting and compacting extrusion granulator includes a compacting cylinder 1 with a cutting knife in the middle, such as figure 2 , image 3 As shown, the inner wall of the compacting cylinder 1 is provided with several streamlined deflectors 2, and the deflectors 2 are distributed along the direction of rotation of the cutting knife in the compacting cylinder 1, and the outer side of the compacting cylinder 1 is connected to Organic cylinder 3, described cylinder 3 comprises feed section cylinder 31 and extrusion section cylinder 32, is provided with feed section screw rod 4 in described feed section cylinder 31, described extrusion section machine Extrusion section screw rod 5 is arranged in bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com