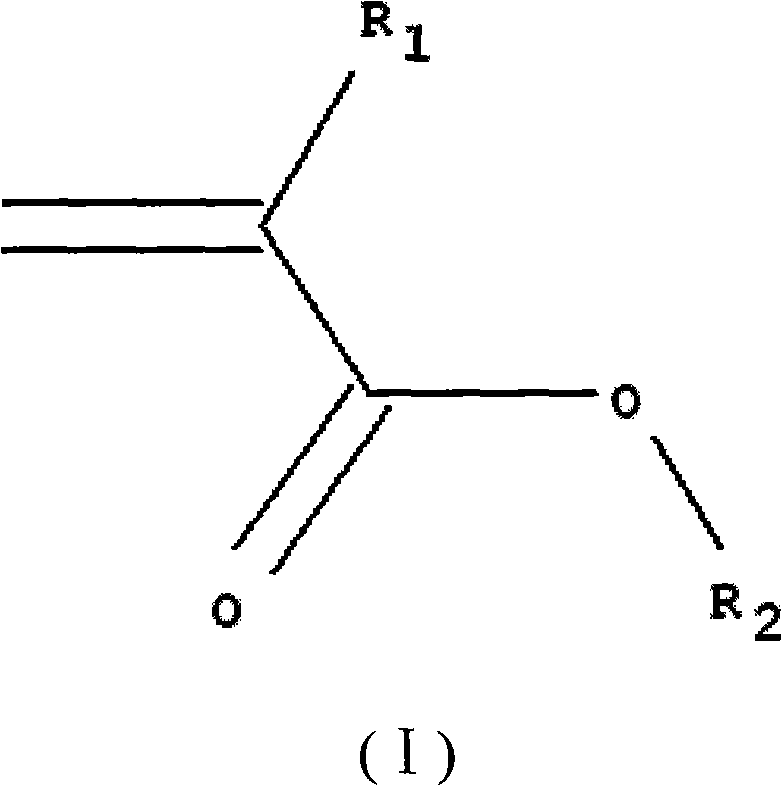

Preparation method of carboxyl-contained polyacrylic ester with low molecular weight

A technology of polyacrylate and acrylate, which is applied in the direction of coating, etc., and can solve problems such as hindering the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

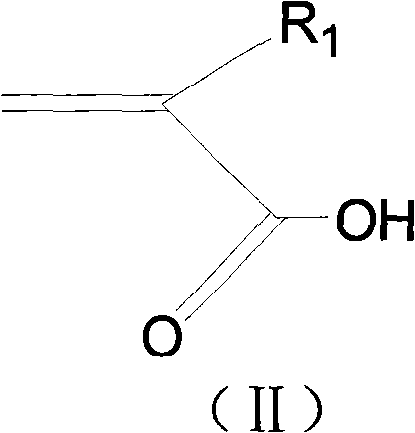

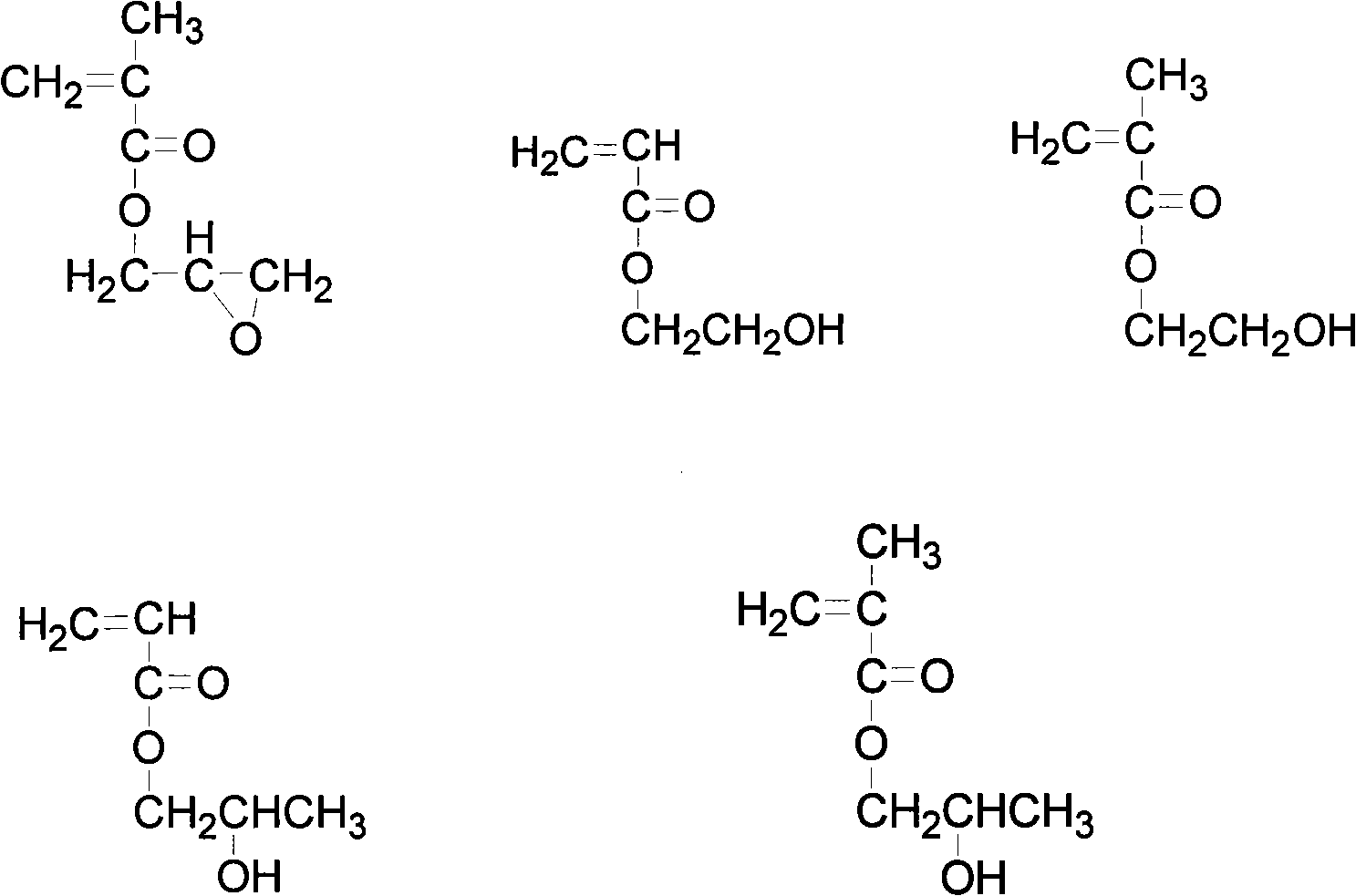

Method used

Image

Examples

Embodiment 1

[0030] The first step is to add acrylic acid (AA), methyl acrylate (MA) and ethyl acrylate (BA) with a molar ratio of 1:1:1 in a reactor equipped with a condenser, a stirrer, and a heating device. Initiator AIBN with 1 mol% of the total amount of monomers is the chain transfer agent n-dodecanethiol [S] with 0.5 mol% of the total amount of monomers, add the solvent toluene, stir and heat to 50°C to dissolve all the reactants, and then heat to 73°C, after one hour of reaction, start to measure the infrared spectrum, wait until 1650cm -1 and 810cm -1 The absorption peak of the acrylate double bond disappears, that is, the reaction is complete.

[0031] The molecular weight (Mn) and molecular weight distribution (PDI) of the product were measured, and the results are shown in Table 1.

[0032] In the second step, the product is dried and dissolved in acetone, and the acid value is measured with KOH ethanol solution as the titrant and phenolphthalein as the indicator. Then, acco...

Embodiment 2~ example 3

[0035] Embodiment 2~Example 3, with embodiment 1, only the consumption of chain transfer agent changes, changes into 2%, 4% respectively.

Embodiment 4

[0037] The first step is to add acrylic acid (AA) and ethyl acrylate (EA) with a molar ratio of 1:2 in a reactor equipped with a condenser, an agitator, and a heating device, and the addition is 0.25mol% of the total amount of monomers Agent AIBN is the chain transfer agent n-dodecanethiol [S] with 3.0mol% of the total amount of monomers. Add the solvent toluene, stir and heat to 50°C and all the reactants are completely dissolved, then heat to 73°C, and react for one hour. Start to measure the infrared spectrum, wait for 1650cm -1 and 810cm -1 The absorption peak of the acrylate double bond disappears, that is, the reaction is complete.

[0038] The molecular weight (Mn) and molecular weight distribution (PDI) of the product were measured, and the results are shown in Table 1.

[0039] In the second step, the product is dried and dissolved in acetone, and the acid value is measured with KOH ethanol solution as the titrant and phenolphthalein as the indicator. Then, accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com