Backlight module

A technology for a backlight module and a light source assembly, which is applied to the field of backlight modules with deviations in assembly positions, can solve the problems of increasing the energy loss of light-emitting diodes 122, poor contact between a flexible circuit board and a connector, and uneven brightness and darkness of a liquid crystal display panel, Achieve the effect of avoiding assembly position deviation, avoiding uneven light and dark, and saving material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, features and effects of the backlight module proposed according to the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. As later.

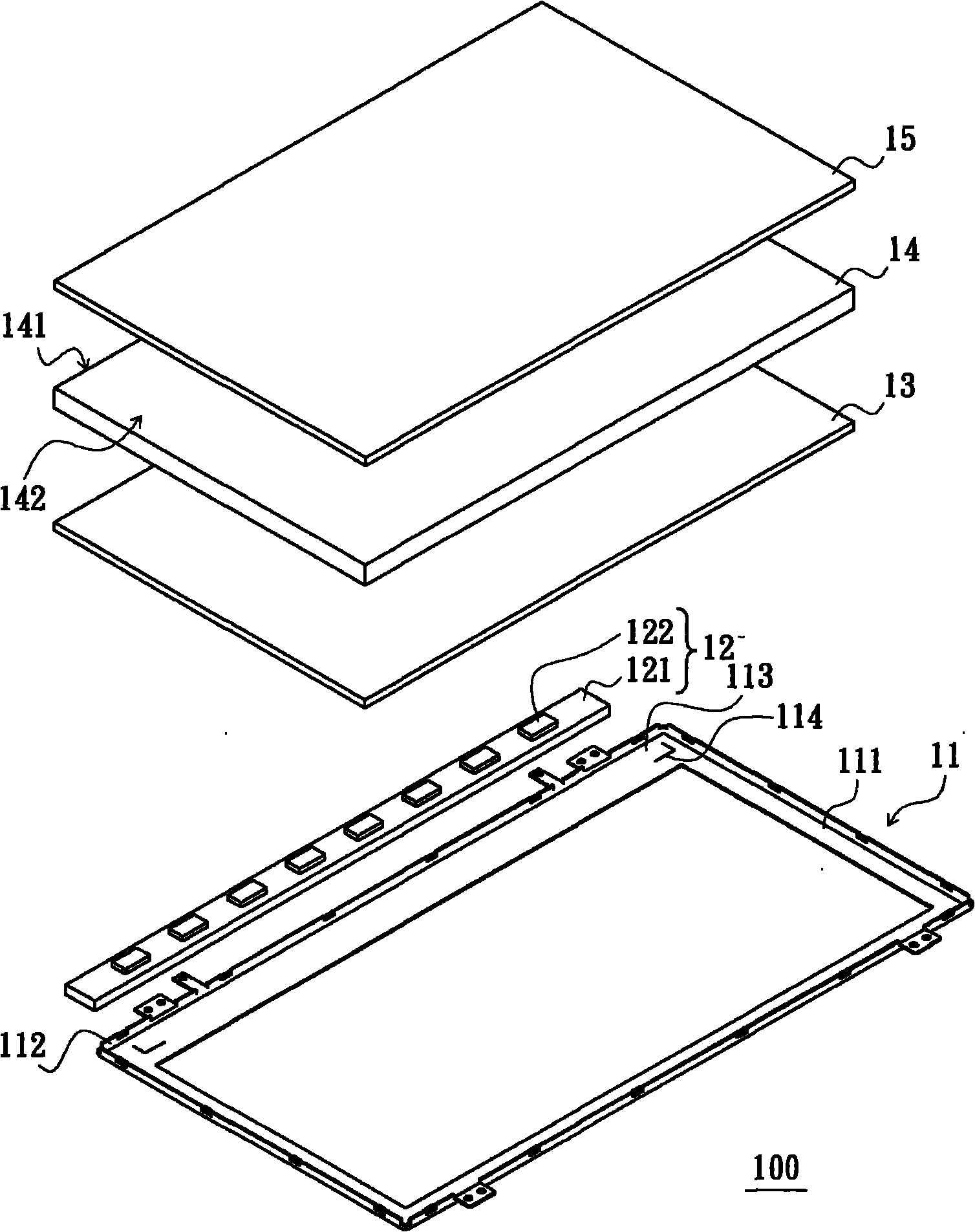

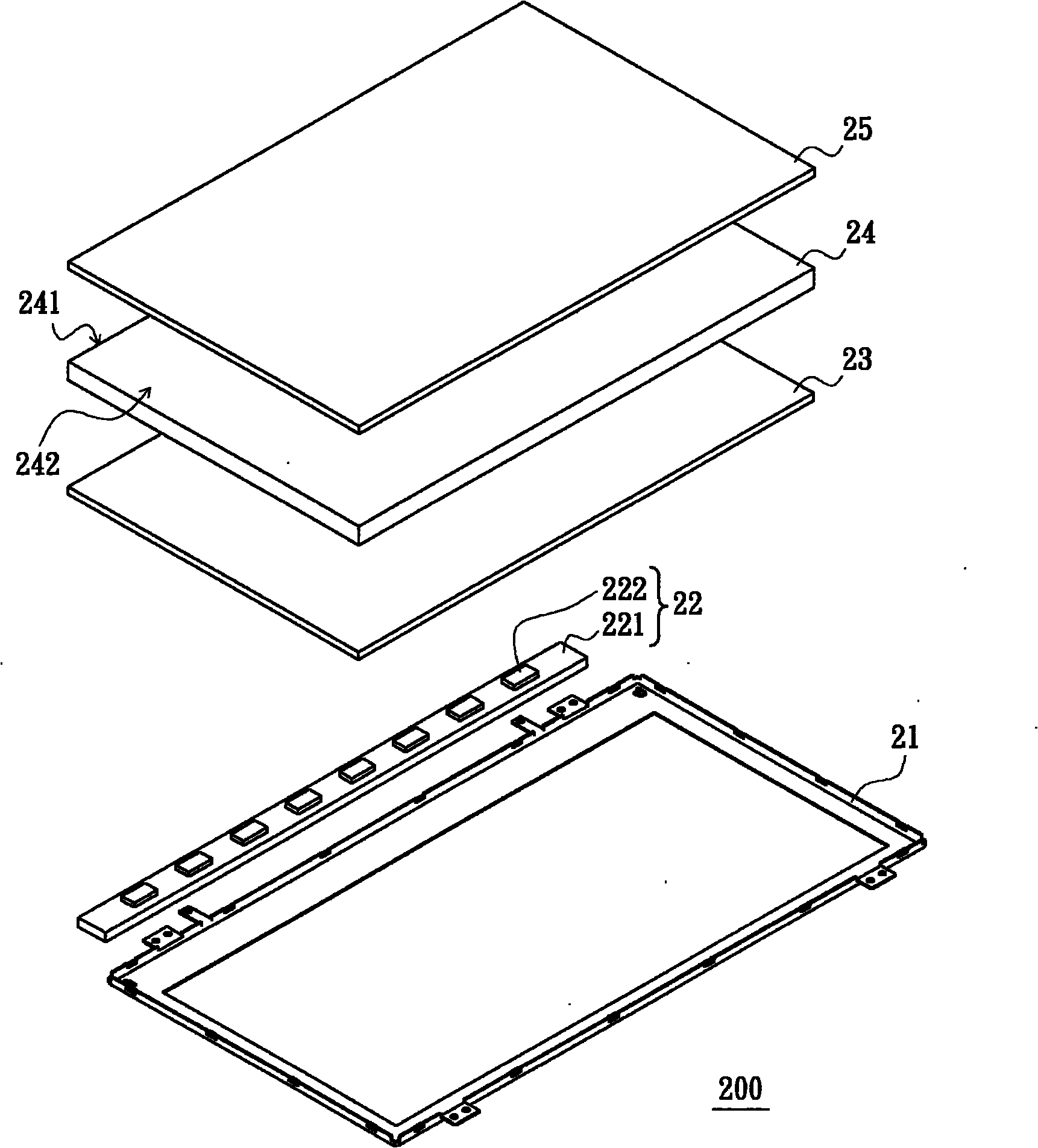

[0050] See figure 2 , the backlight module 200 is an edge-lit backlight module, which includes a frame 21 and a light source assembly 22 .

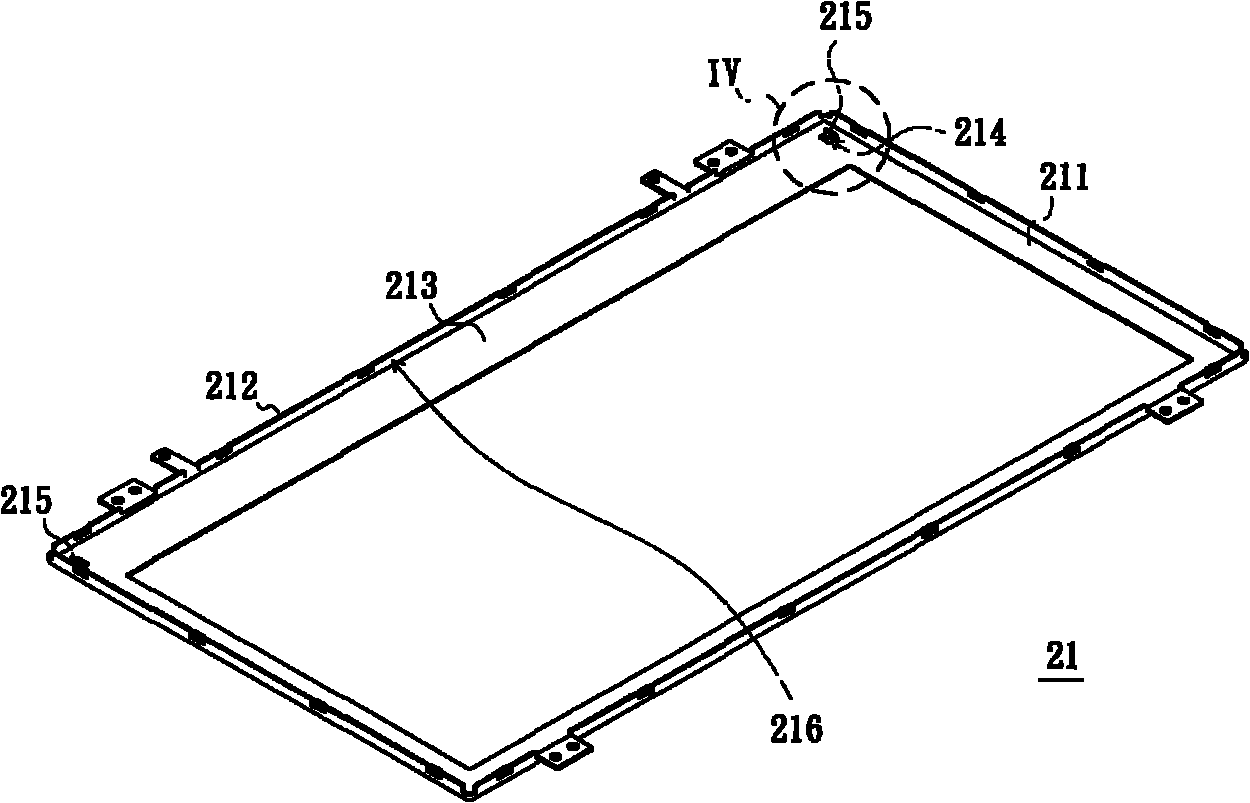

[0051] See image 3 and Figure 4 , the frame 21 includes a bottom plate 211 and a side wall 212 connected to an edge of the bottom plate 211 . The material of the frame 21 includes metal, such as aluminum or its alloys, or magnesium or its alloys, for example. The bottom plate 211 has a light source carrying portion 213 , and two opposite ends of the light source carrying portion 213 respectively define through holes 214 . A blocking piece 215 extends from an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com