Automatic axial internal clearance measuring meter for tapered roller bearing of automobile gearbox

A technology for tapered roller bearings and automobile gearboxes, which is applied in measuring devices, instruments, and electrical devices, can solve problems such as excessive axial clearance, noise, and large human errors, and ensure the safety of automobiles. Guarantee the effect of stability and high efficiency requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0033] The specific embodiment: the specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

Embodiment

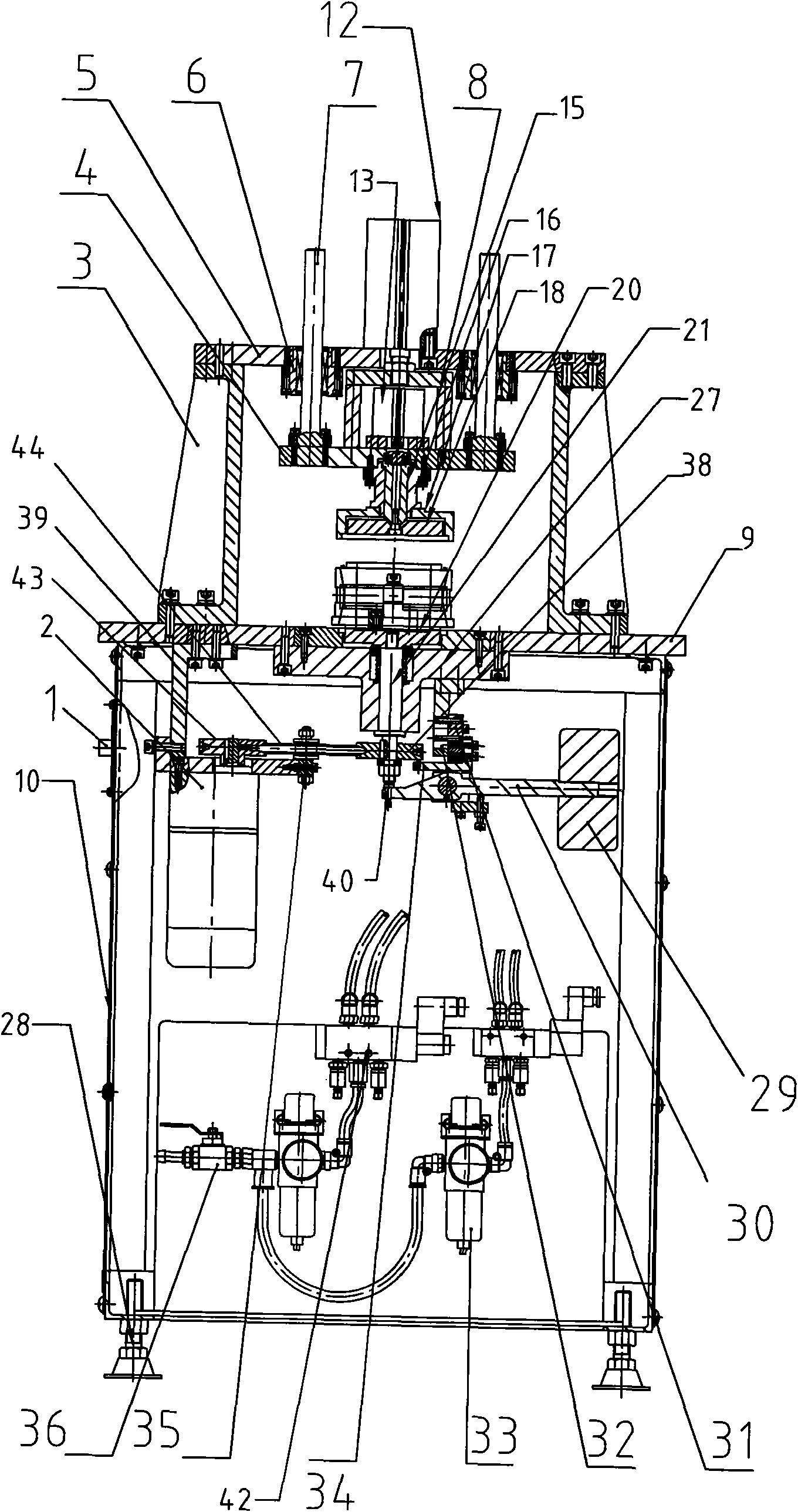

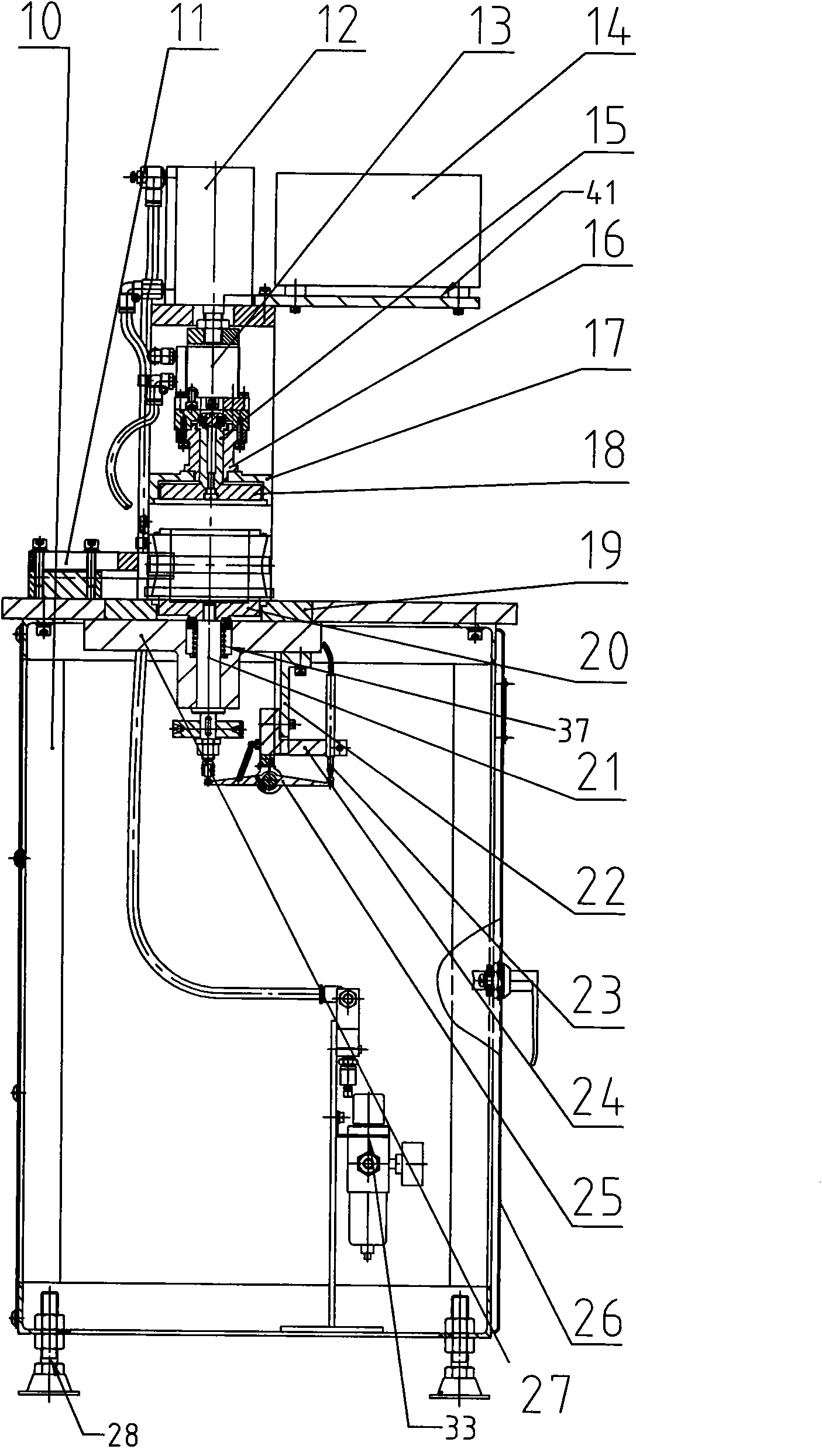

[0034] Embodiment: a kind of automatic measuring instrument for axial clearance of tapered roller bearing of automobile gearbox (see Figure 1-Figure 6 ), it has a frame body 10, the frame body 10 is supported by four corners 28, and the frame body 10 front is provided with a door 26 for opening.

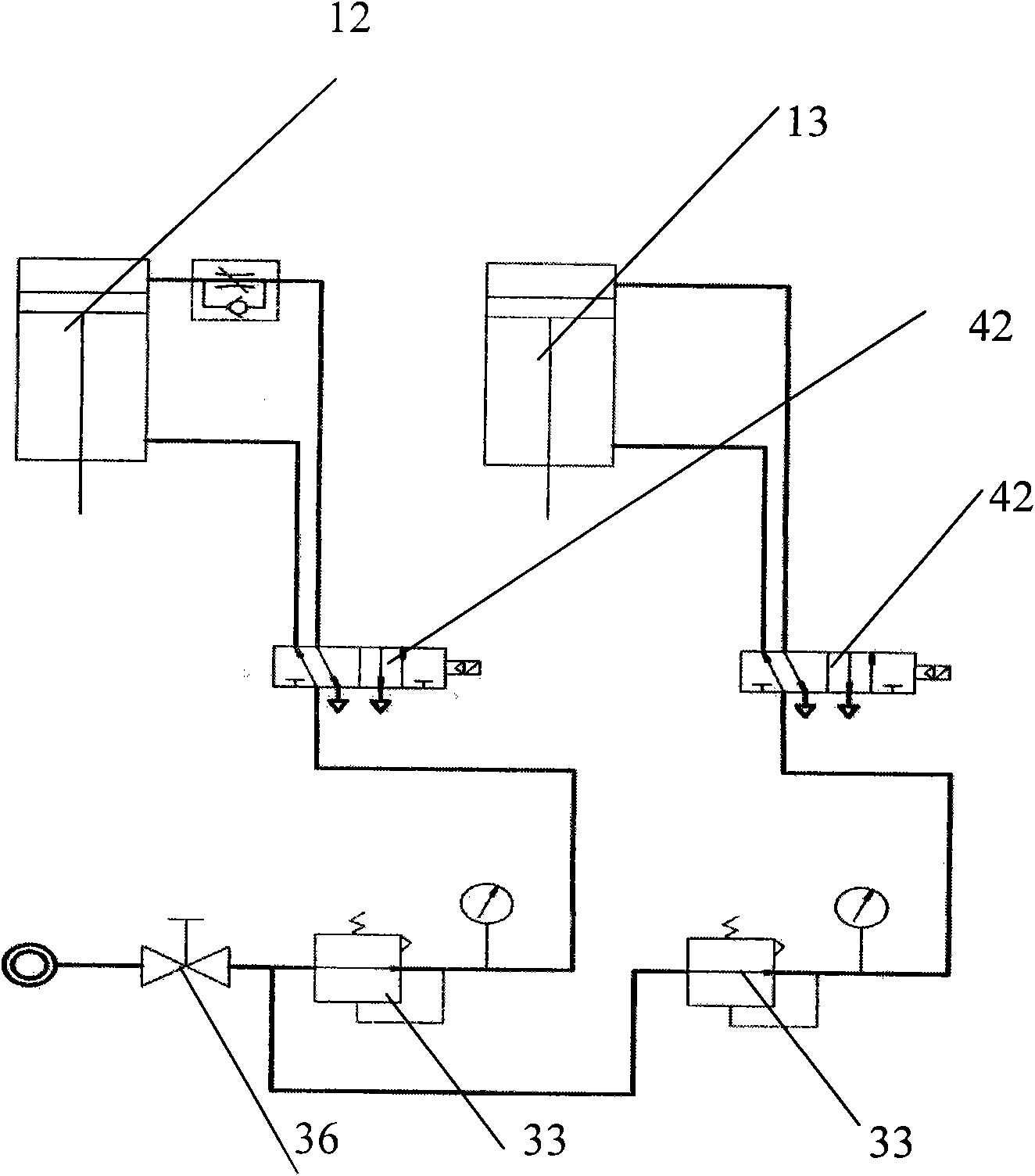

[0035] The workbench 9 is fixed on the frame body 10, the lower end middle part of the workbench 9 in the frame body 10 is provided with a lower outer pedestal 27, the lower outer pedestal 27 is equipped with a lower rotating shaft 21, and the lower rotating shaft 21 is covered with a spring 37, and the lower rotating shaft 21 The upper end is connected to the lower inner platform 20, and the lower inner platform 20 should be reliably reset under the action of the spring force; the lower part of the lower rotating shaft 21 is connected to the belt driven pulley 38, which does not affect the up and down movement of the lower rotating shaft 21, and its end is pressed with steel balls 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com