Manufacturing method of lamp tube for lamp with cover

A manufacturing method and lamp technology, which are applied in the field of lighting, can solve the problem of easy flow of amalgam in lamps with a cover, and achieve the effects of improving the luminous flux maintenance rate, simplifying the process, and being easy to popularize.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

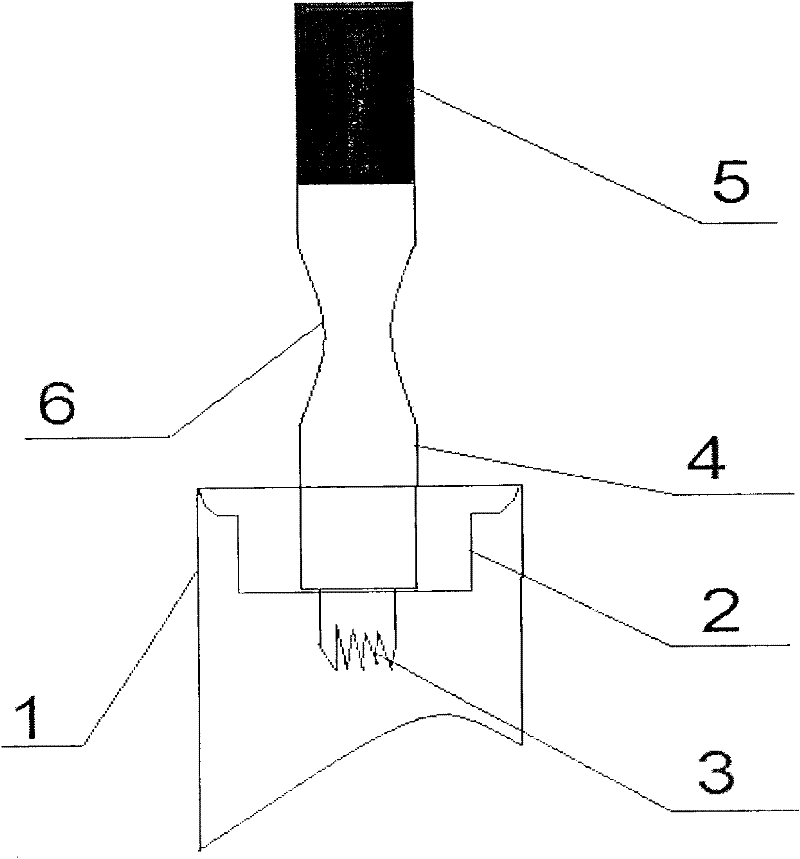

[0010] Embodiment 1, a lamp tube with a cover lamp, comprising a tube body 1 and a stem 2, the stem 2 is provided with a filament 3 and an exhaust pipe 4, and an amalgam 5 is housed in the exhaust pipe 4, so The above-mentioned exhaust pipe 4 has partly flattened 6, and the amalgam 5 is located in the exhaust pipe above the flattened 6. The length is 3-10mm.

Embodiment 2

[0011] Embodiment 2, manufacture the above-mentioned lamp tube with cover lamp, take the tube body that has been sealed, connect the foot to inject mercury, exhaust, seal off, seal off, and then insert the lamp tube exhaust pipe downward into a 200-400 degree Celsius Heat in the oven until the amalgam and the glass at the top of the exhaust pipe are completely melted, vibrate the pipe body to make the amalgam and the glass at the top of the exhaust pipe dense, remove it from the oven and let it cool naturally. Burn flat.

Embodiment 3

[0012] Example 3: To manufacture the above-mentioned lamp tube with cover lamp, clamp the exhaust pipe of the core column with a machine part, seal the tube body of the core column, exhaust and inject mercury, then seal off, and then exhaust the lamp tube The tube is inserted downward into an oven at 200-400 degrees Celsius and heated until the amalgam and the top glass of the exhaust pipe are completely melted, and finally the tube is vibrated until the amalgam and the glass on the top of the exhaust pipe are dense, and then removed from the oven to cool naturally.

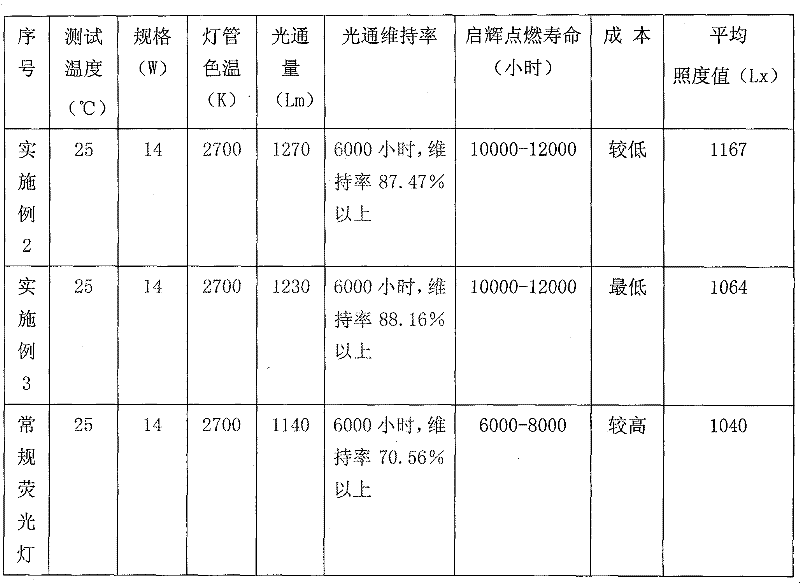

[0013] The performance comparison table of the lamp tube made according to the methods of Examples 2 and 3 and the lamp tube made by the conventional method is as follows. In order to ensure the uniformity and comparability of the test data, the number of samples in each group of statistical experiments is 50, the specifications of the lamp tubes are all uniform, the power is 14W, the color temperature is 2700K, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com