High power LED driving power supply

A LED driving, high-power technology, applied in the direction of electric light source, light source, lamp circuit layout, etc., can solve the problems of high cost, unstable circuit, difficult to pass EMI test, etc., to save cost, ensure reliability, avoid multiple The effect of mutual interference of road switch signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

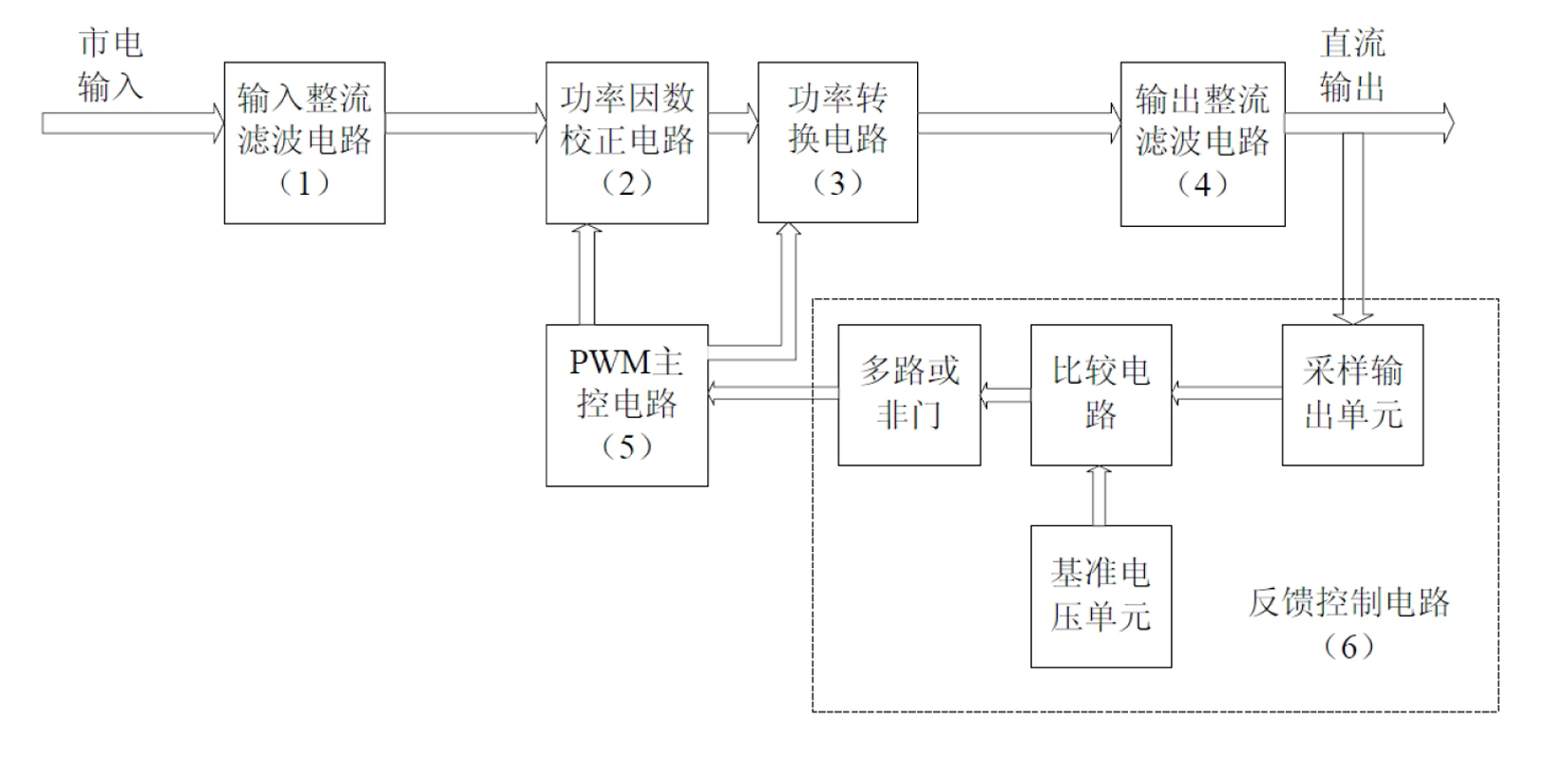

[0016] refer to figure 1 High-power LED drive power supply, including input rectification and filtering circuit 1, power factor correction circuit 2, power conversion circuit 3, output rectification and filtering circuit 4 and PWM main control circuit 5, the mains power passes through rectification and filtering circuit 1, power factor correction circuit 2 in turn , the power conversion circuit 3, and the output rectification filter circuit 4 become DC voltage, the PWM main control circuit 5 is connected with the control terminals of the power factor correction circuit 2 and the power conversion circuit 3 respectively, and the high-power LED driving power supply also includes a feedback Control circuit 6 , the input end of the feedback control circuit 6 is connected to the output end of the output rectification filter circuit 4 , and the output end of the feedback control circuit 6 is connected to the PWM main control circuit 5 .

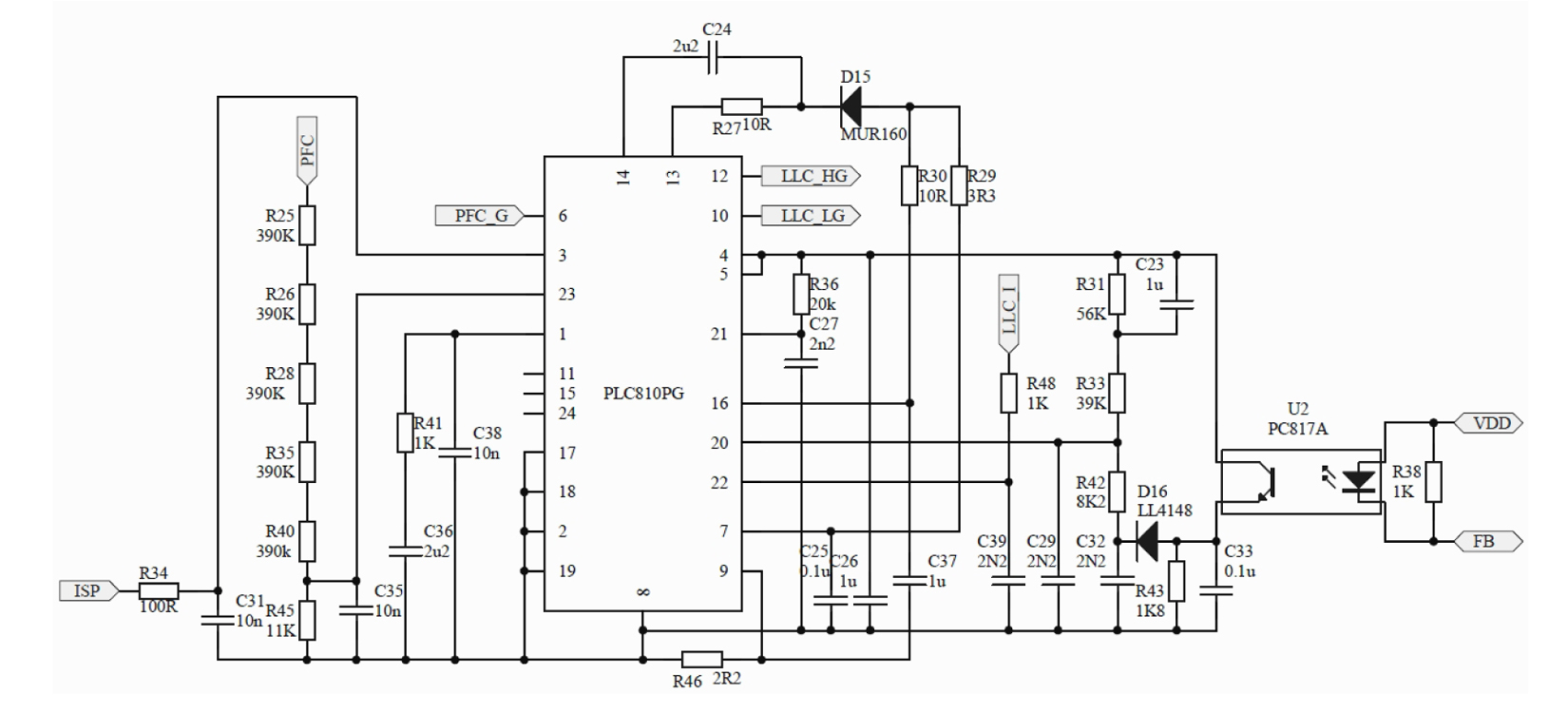

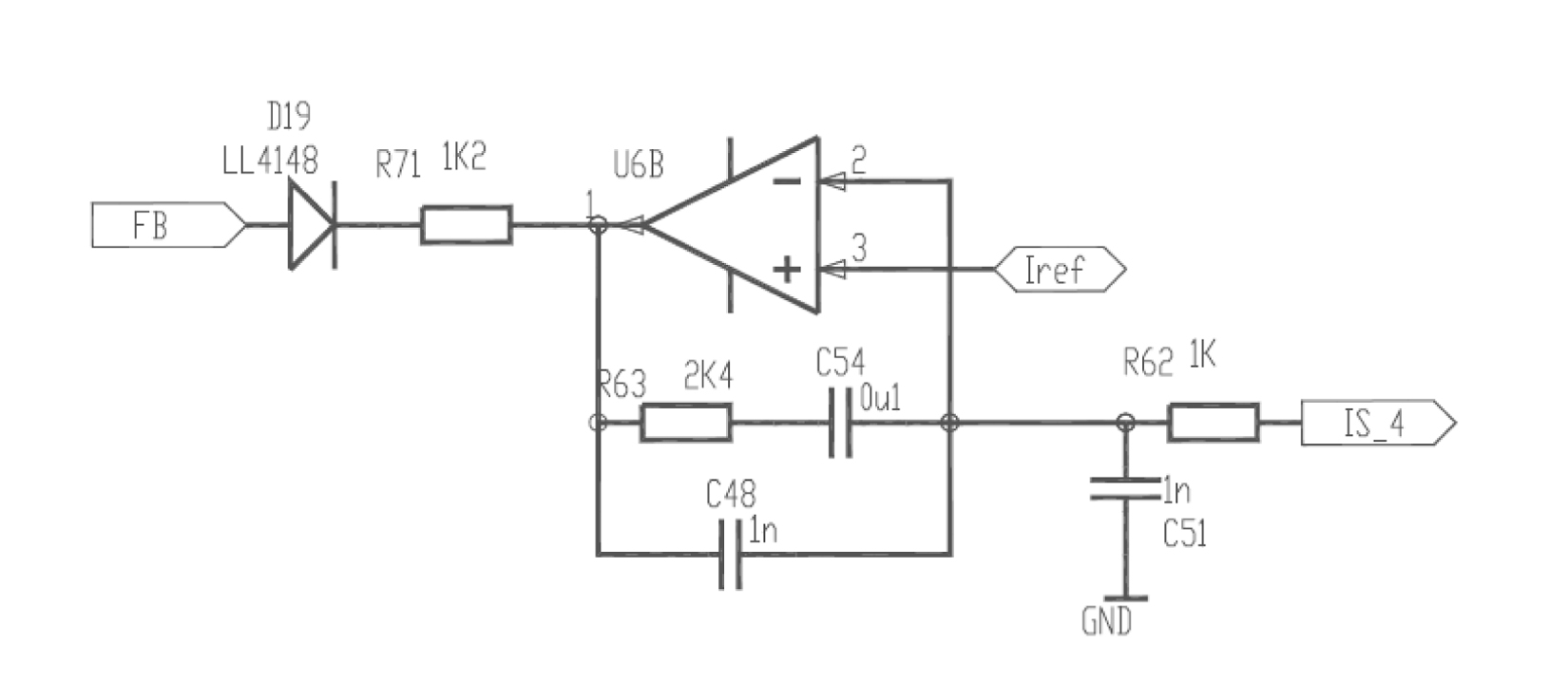

[0017] Further, the feedback control circuit ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap