Compact injection device with reduced tendency to form vapor bubbles

A technology of injection devices and injectors, which is applied in the direction of fuel injection devices, charging systems, secondary air defueling, etc., and can solve problems such as large structural space and complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

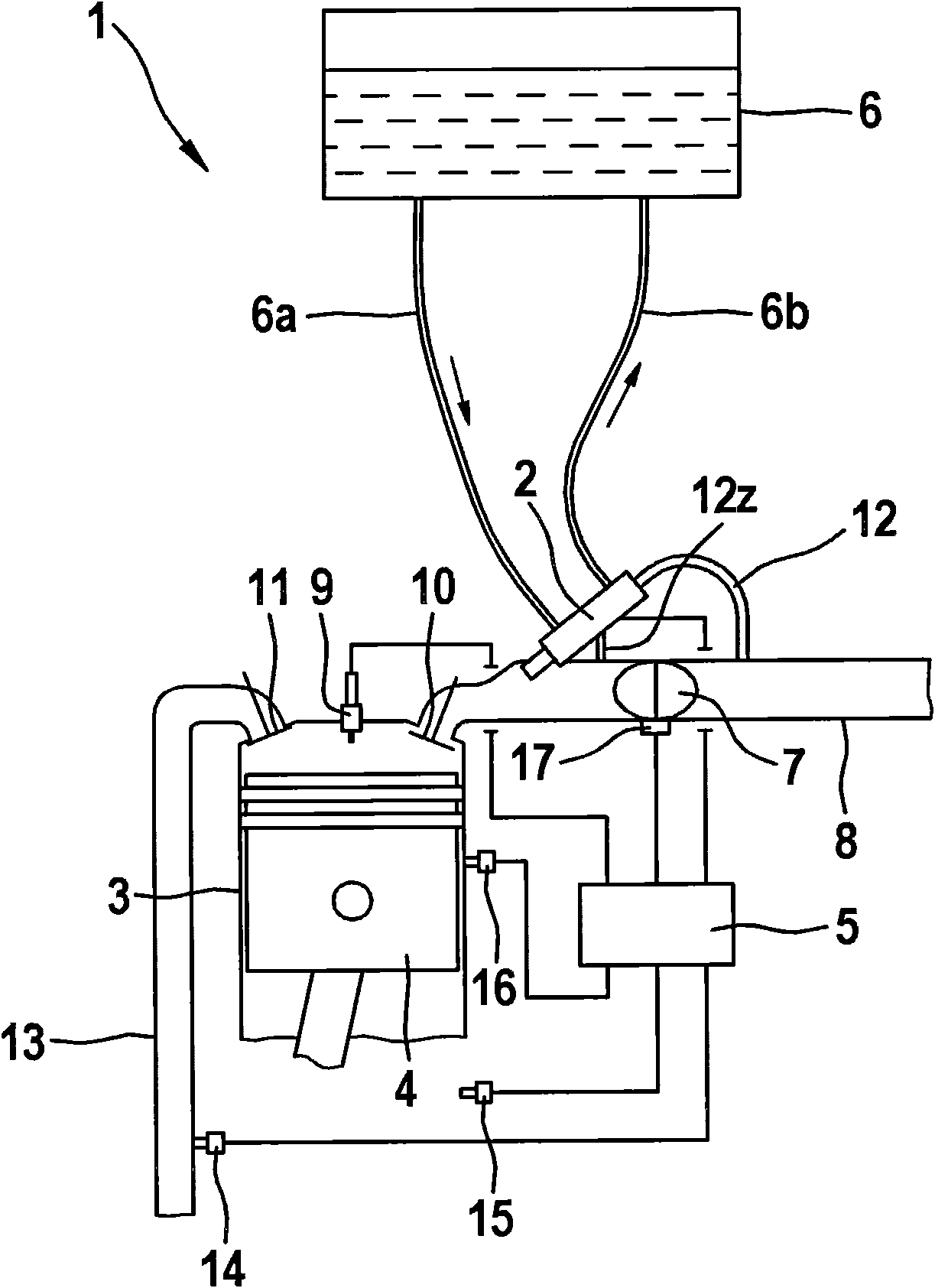

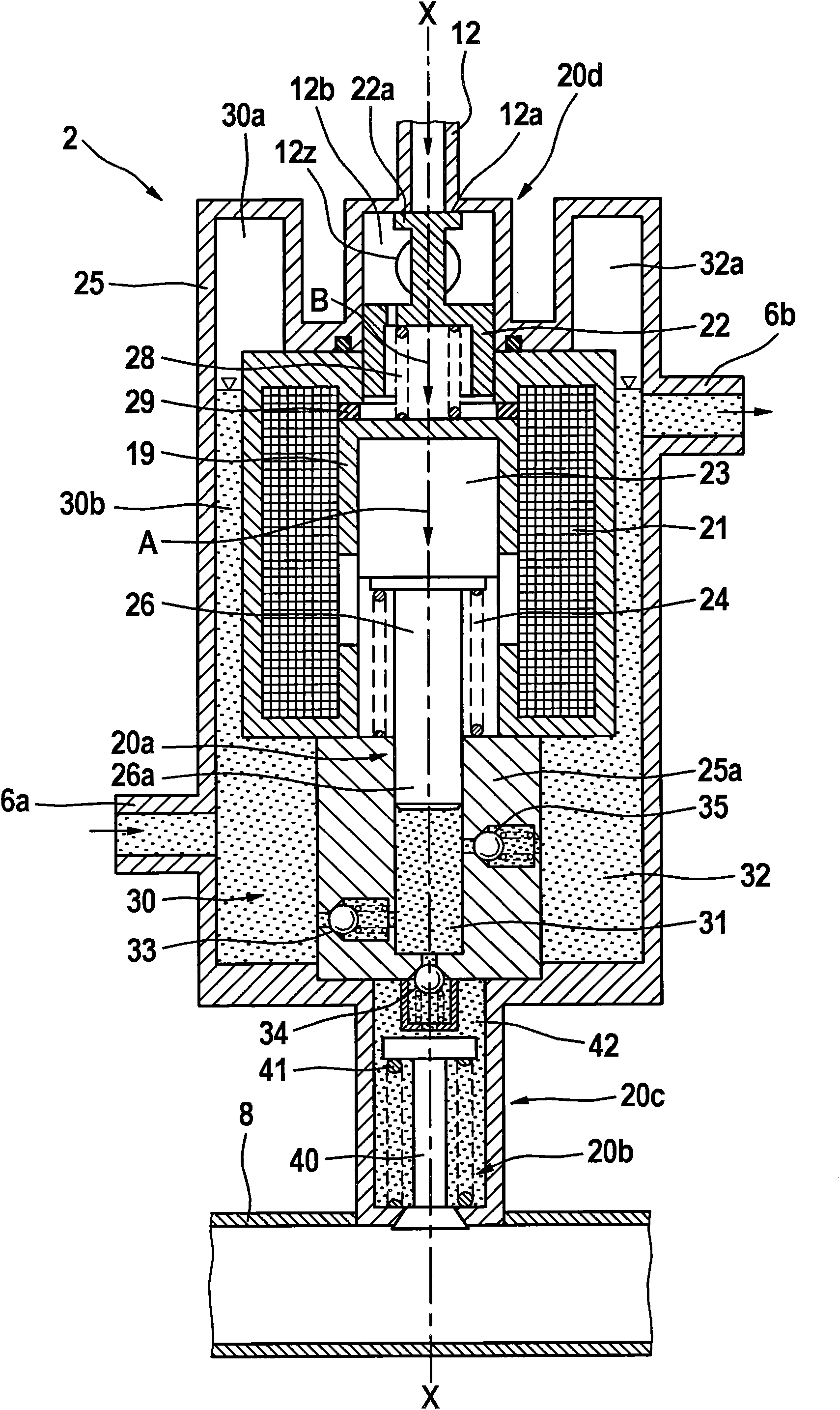

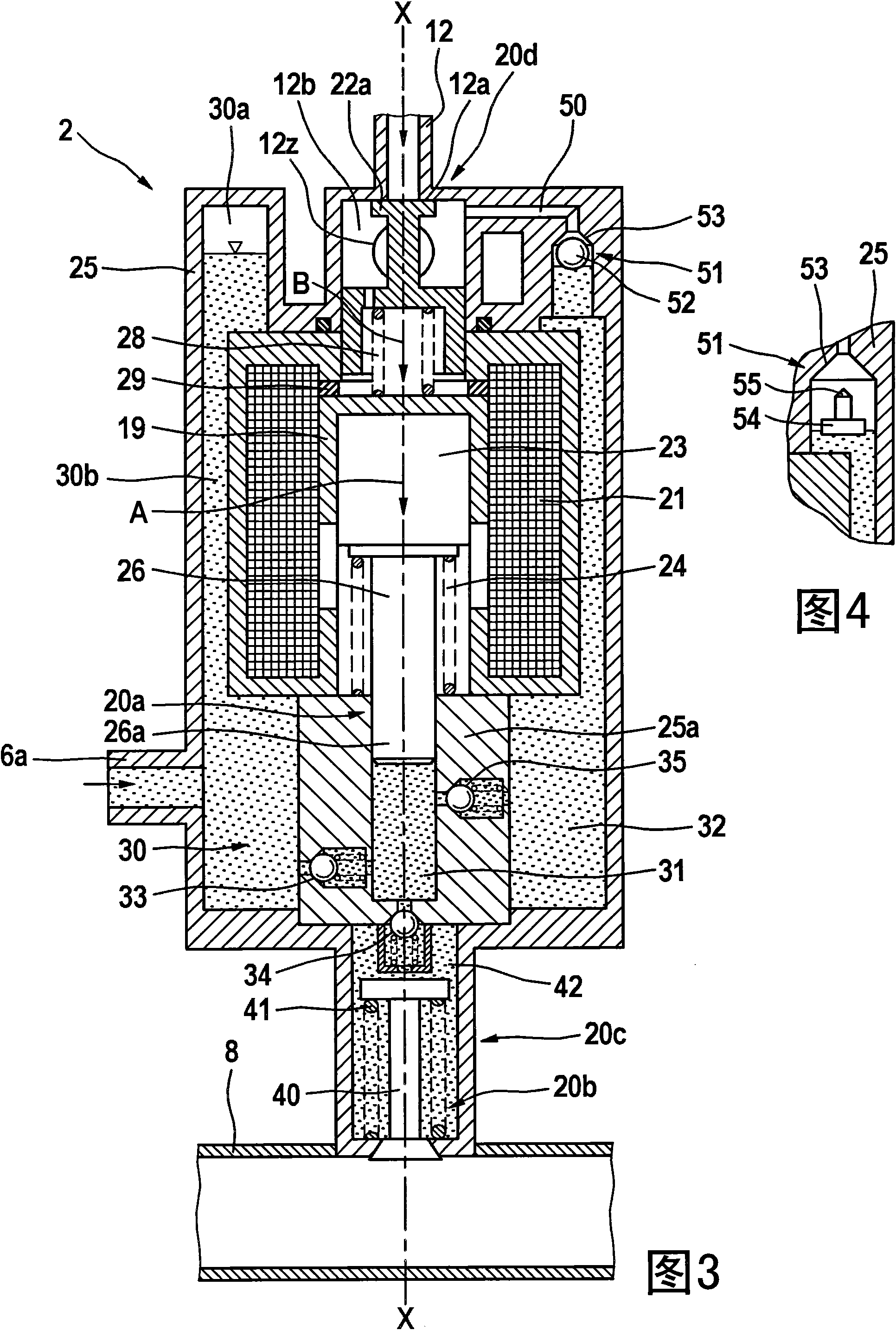

[0027] Refer below Figure 1 to Figure 4 A small engine 1 having an inventive injection device according to a first embodiment will now be described in detail.

[0028] figure 1 The structure of a small engine 1 is shown schematically, which is designed as a single-cylinder engine. The small engine 1 comprises a cylinder 3 , a piston 4 reciprocable in the cylinder, a control unit 5 and a container 6 . The container 6 is connected to the injection module 2 via a fuel feed line 6a. A fuel return line 6 b returns from the injection module 2 to the container 6 . Such as figure 1 As shown schematically in , the container 6 is arranged above the injection module 2 . As a result, the fuel flows via the fuel feed line 6a to the injection module 2 on the basis of gravity. The injection module 2 shown very schematically comprises a fuel pump, an injector with an integrated pressure regulator and an air conditioner, whereby the injection module 2 is constructed very compactly.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com