Method and conveyor belt system having at least one conveyor belt for transporting flat transport goods

A conveyor belt, conveying direction technology, applied in the direction of conveyor objects, conveyors, transportation and packaging, etc., can solve problems such as damage, and achieve the effect of reducing energy demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

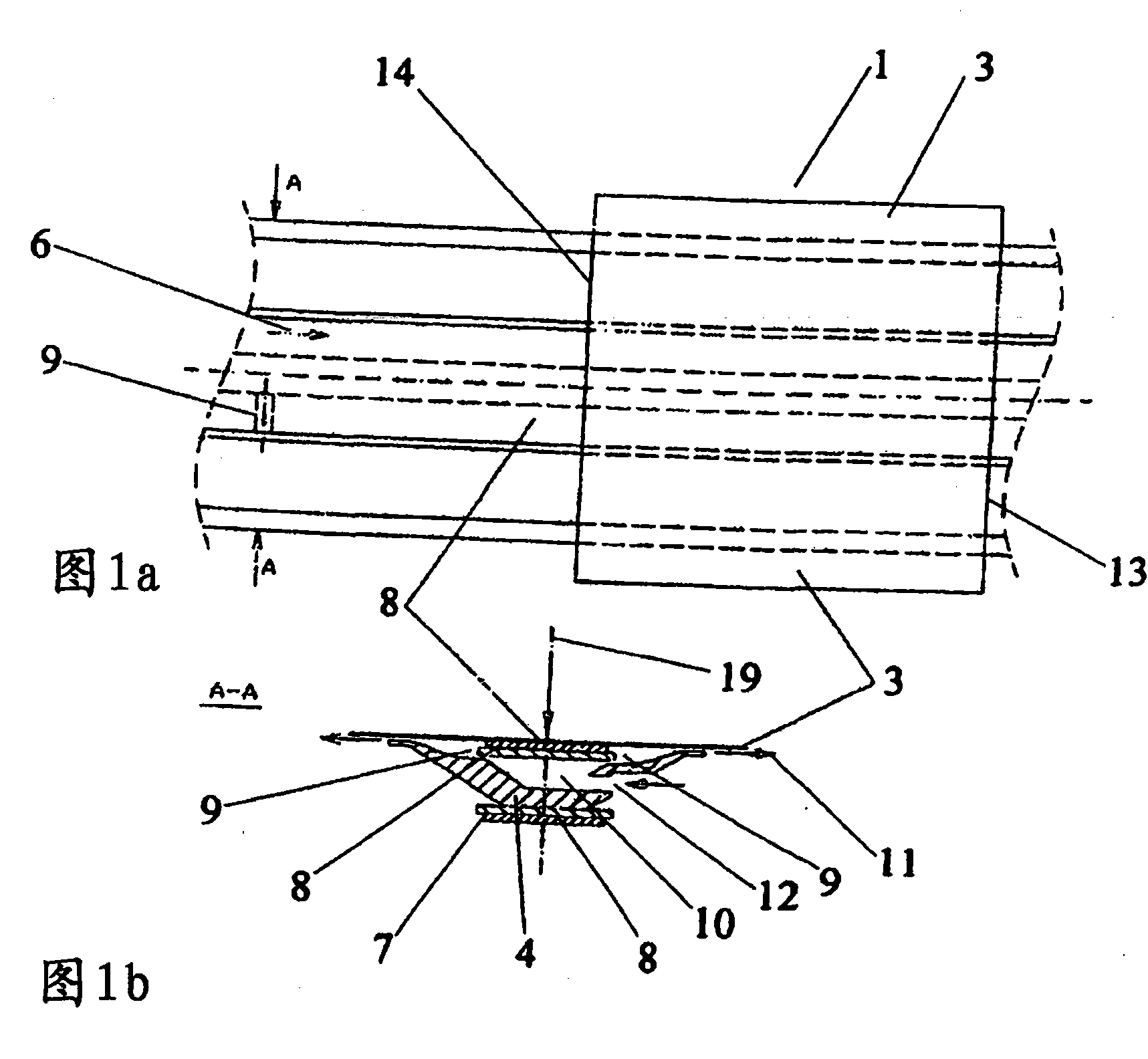

[0030] as in Figure 1a It can be seen from the schematically shown embodiment of a conveyor belt system 1 which has a conveyor belt 2 and a Bernoulli suction device 4, which is used to transport substrates, such as silicon wafers and solar cells, so that Super Bernoulli suction device 4 in Figure 1b China and Israel pass Figure 1a A sectional view of the plane A-A is shown. Along each longitudinal edge 7 of the belt 8 of the conveyor belt 2 extending in the conveying direction 6, the Bernoulli suction devices 4 each have at least one outflow opening 9 of a chamber 10 at mutually corresponding positions, said The chamber is supplied with compressed air 11 via inlet openings 12 from a compressed air source, not shown. The cross section of the inflow opening 12 is larger than the cross section of the outflow opening 9 of the chamber 10 . The substrate 3 is brought into surface contact by a force acting in the direction of arrow 19 by means of a pressure difference between at...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap