Method for removing welding spots

A technology of solder joints and solder pads, applied in the field of semiconductor manufacturing, can solve the problems of low operating cost, low operating technical requirements, and small design application field limitations, so as to avoid damage and achieve the effect of secondary utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

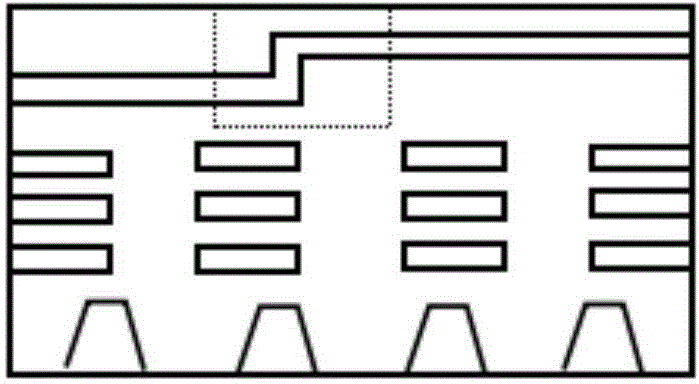

[0032] The invention provides a method for removing solder joints, which can be applied to processes with technology nodes of 90nm, 65 / 55nm, 45 / 40nm, 32 / 28nm, greater than or equal to 130nm and less than or equal to 22nm; it can be applied to the following technical platforms: Logic, Memory, RF, HV, Analog / Power, MEMS, CIS, Flash, eFlash, and Package.

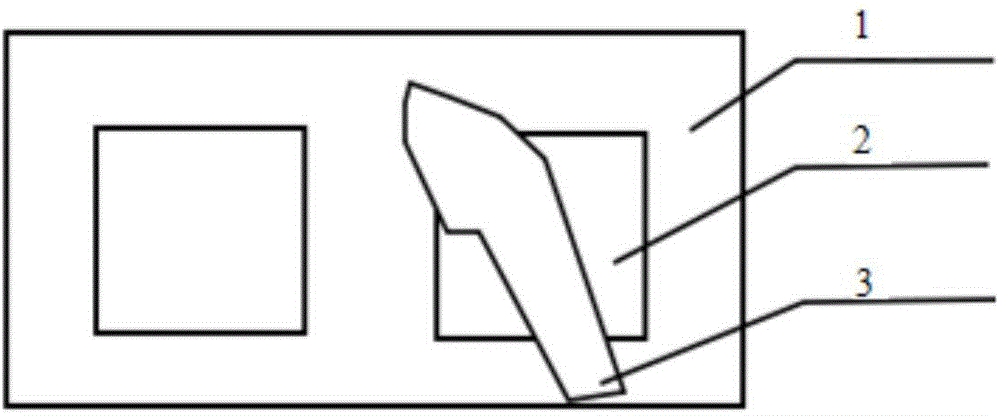

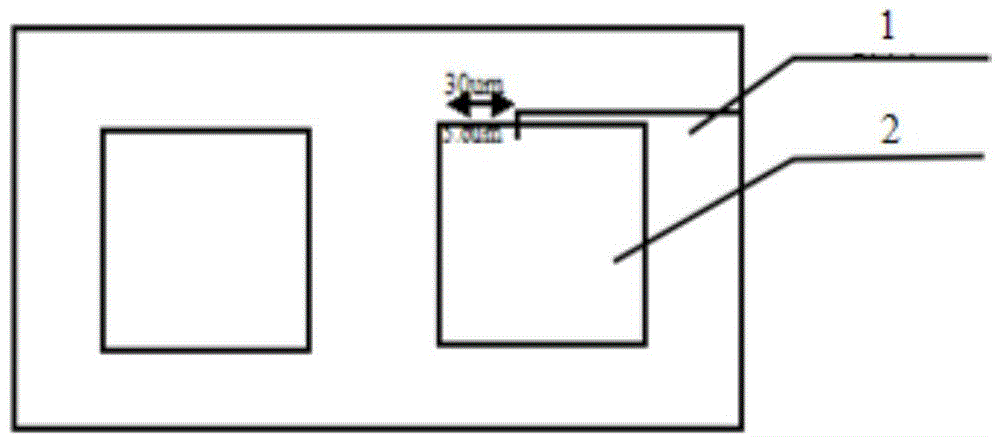

[0033] The present invention is a method for removing solder joints, which is applied to chips containing and testing structures. The solder joints are located on the upper layer of the test structures and partially or completely block the test structures. The method mainly includes the following steps:

[0034] Step S1, removing the metal wire connected to a welding pad through the welding spot;

[0035] Step S2, fixing the chip with the metal wire removed on the sample stage of a probe station;

[0036] Step S3, using the tip of the probe to push the root of the solder joint to completely separate the solder joint from the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com