Gas-solid centrifugal separation and exhaust integrated machine

A technology of centrifugal separation and gas-solid separation, applied in the direction of cyclone devices, etc., can solve problems such as additional energy consumption, and achieve the effects of increasing energy consumption, improving separation efficiency, and reducing floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] specific implementation plan

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

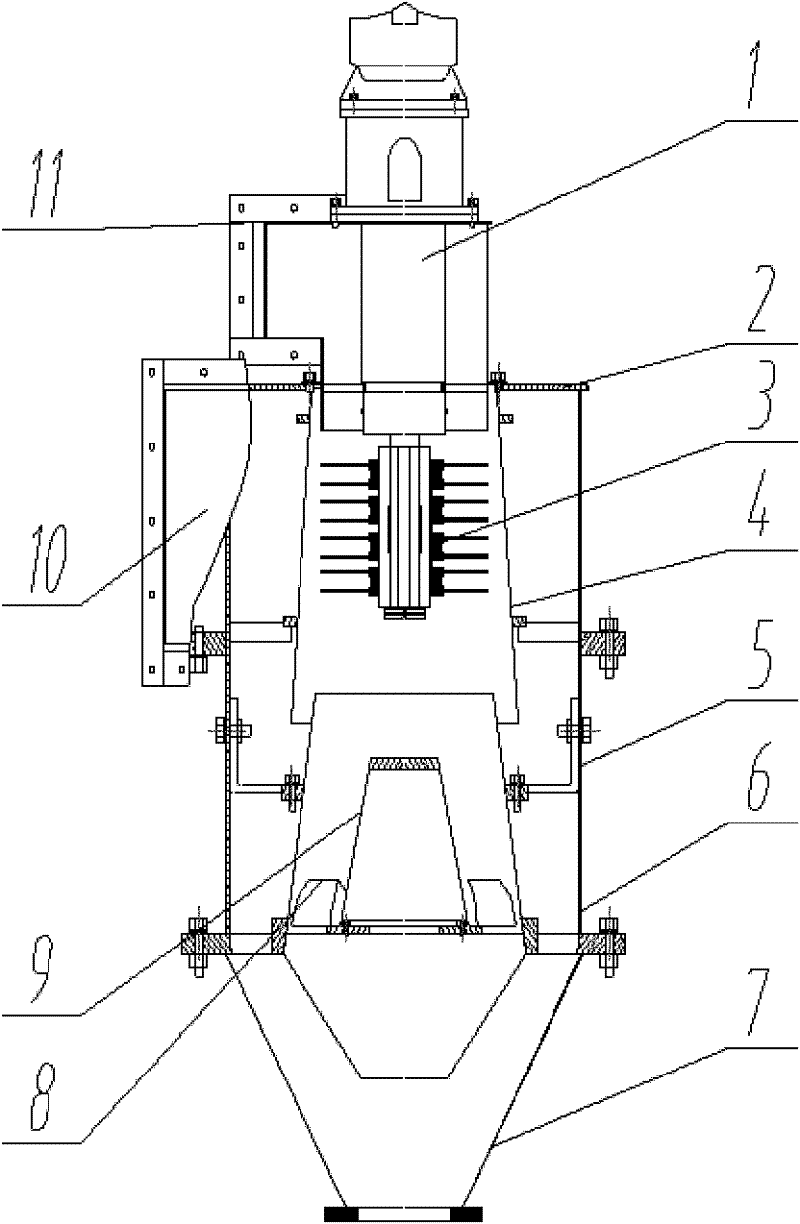

[0039] Such as Figure 4-5 As shown, a gas-solid centrifugal separation and exhaust integrated machine is composed of a rotor system and a stator system. The rotor system is mounted on the stator system. The stator system is mounted on a foundation frame (frame not shown). During work, the rotor system rotates at a fixed axis in the stator system driven by the motor (the motor is not marked).

[0040] The rotor system includes centrifugal fan impeller 3, rotating gas-solid separation chamber assembly 4, isolation cylinder 5, central exhaust pipe 6, vortex shield 7, rotating dust storage chamber and dust extractor assembly 9, hydraulic cylinder 10, shaft 11, etc. part.

[0041] The impeller 3 of the centrifugal fan is fixed on the shaft 11, is arranged on the upper end of the integrated machine, rotates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com