Arc protection fabric, manufacturing method and application thereof

An anti-arc, fabric technology, applied in the direction of applications, chemical instruments and methods, protective clothing, etc., can solve the problems of restricted activities, heavy wearing, poor moisture transmission, etc., achieve good flame retardancy and heat insulation performance, manufacturing The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Flame retardant outer layer: using meta-aramid fiber as the main raw material, using X-FIPER from Yuhe Company, gram weight 150g / m 2

[0027] Insulation layer: using meta-aramid fiber as the main raw material, using X-FIPER from Yuhe Company, gram weight 100g / m 2

[0028] Flame retardant inner layer: flame retardant viscose, gram weight 80g / m 2

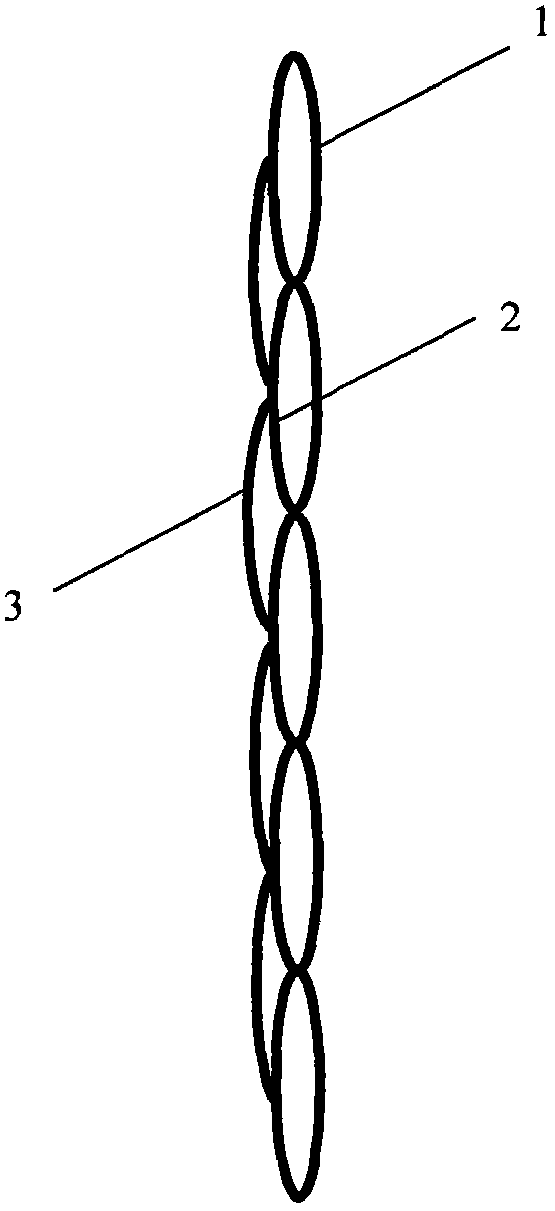

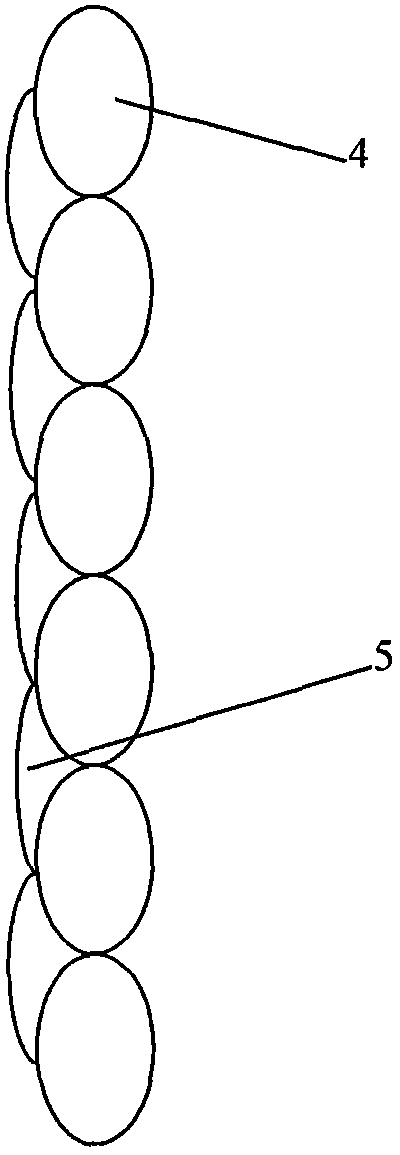

[0029] The adjacent two layers are compounded by the method of quilting, and the width of the pipe layer is 10mm.

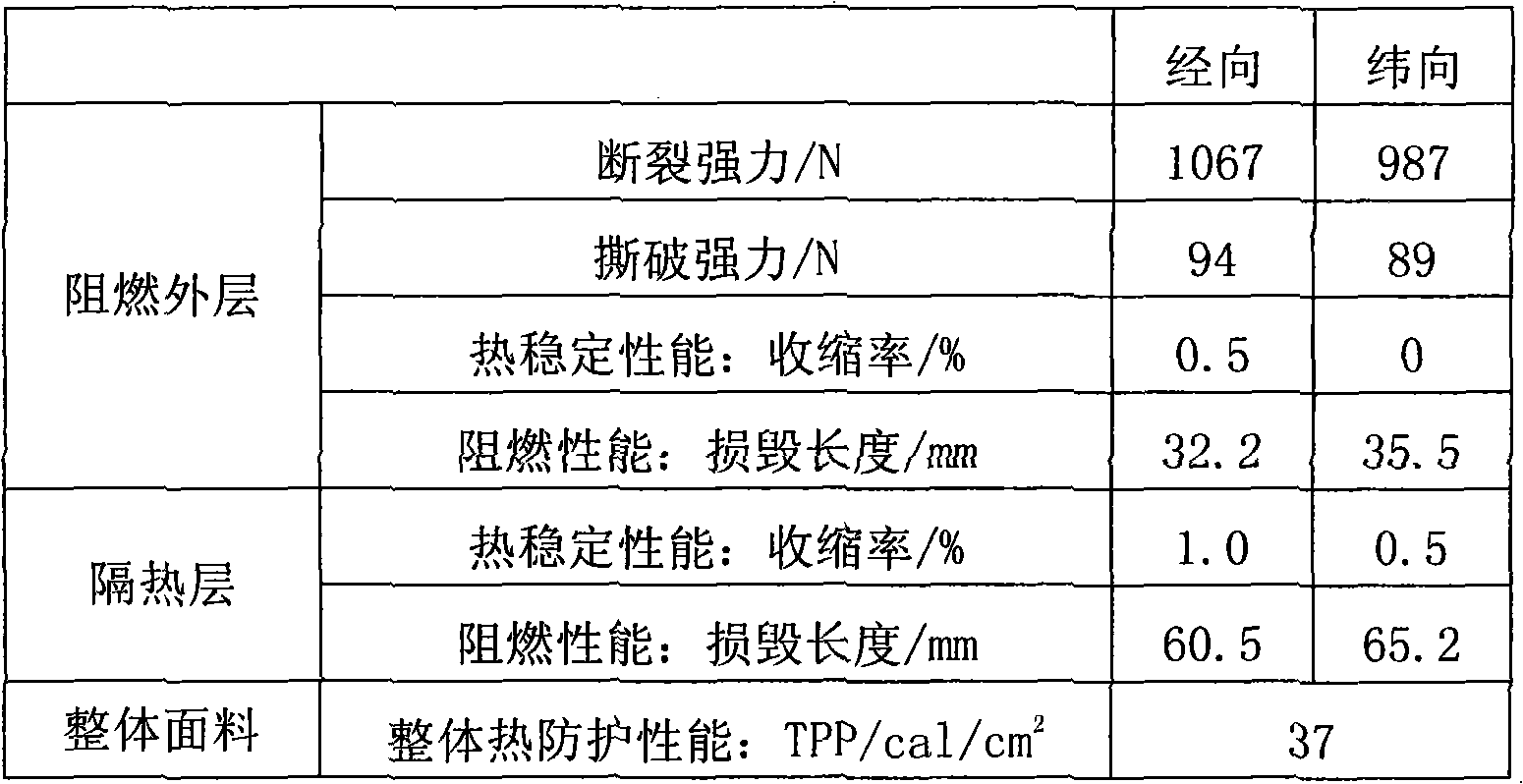

[0030] Perform the following physical property tests on one or a combination of the above fabrics:

[0031] Flame retardant outer layer: breaking strength is tested according to GB3923.1-1997

[0032] Tear strength is tested according to GB3917.3-1997

[0033] Thermal stability is tested according to GA10-2002

[0034] Flame retardant properties are tested according to GB / T5455-1997

[0035] Insulation layer: Stability test according to GA10-2002

[0036] Flame retard...

Embodiment 2

[0043] Flame retardant outer layer: using meta-aramid fiber as the main raw material, using X-FIPER from Yuhe Company, gram weight 150g / m 2

[0044] Insulation layer: using meta-aramid fiber as the main raw material, using X-FIPER from Yuhe Company, gram weight 100g / m 2

[0045] Flame retardant inner layer: flame retardant viscose, gram weight 80g / m 2

[0046] The adjacent two layers are compounded by the method of quilting, and the width of the pipe layer is 20mm.

[0047] The fabric was tested as in Example 1 and the results are shown in Table 2.

[0048] Table 2

[0049]

Embodiment 3

[0051] Flame retardant outer layer: using meta-aramid fiber as the main raw material, using X-FIPER from Yuhe Company, gram weight 150g / m 2

[0052] Insulation layer: flame retardant viscose fiber as the main raw material, gram weight 100g / m 2

[0053] Flame retardant inner layer: flame retardant viscose fiber, weight 80g / m 2

[0054] The adjacent two layers are compounded by the method of quilting, and the width of the pipe layer is 10mm.

[0055] The fabric was tested as in Example 1 and the results are shown in Table 3.

[0056] table 3

[0057]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com