Magnetic suspension linear guide rail with differential-type serial magnetic circuit structure

A technology of series magnetic circuits and linear guide rails, which is applied in the direction of electric power rails, electric vehicles, magnetic attraction or thrust holding devices, etc., can solve the problems of large volume and weight, large ampere-turns of electric excitation, etc., and achieve small size, Low loss and temperature rise, simple control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

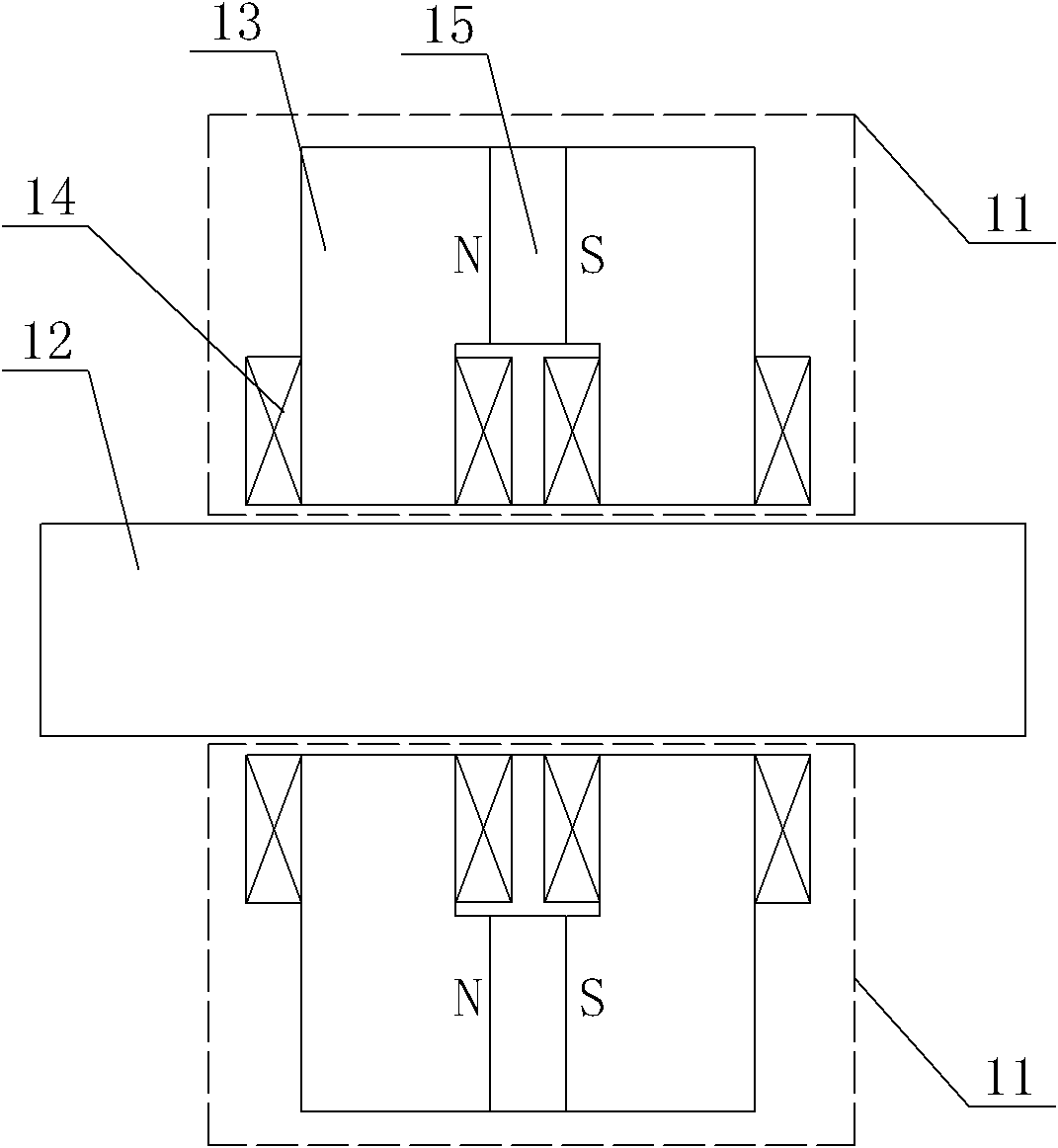

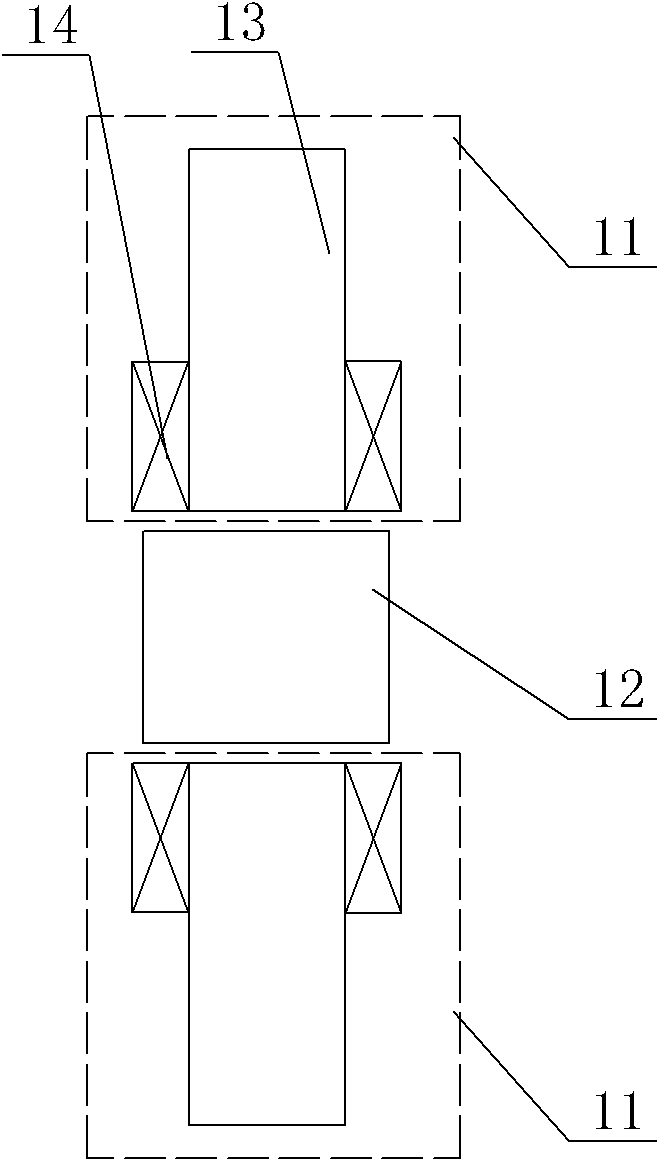

[0030] Specific implementation mode one: the following combination Figures 1 to 4 Describe this embodiment, the differential series magnetic circuit structure magnetic levitation linear guide described in this embodiment is composed of a primary and a secondary, the primary is composed of two primary units 11, and the two primary units 11 are symmetrically arranged on the the upper and lower sides of the secondary;

[0031] The primary unit 11 is composed of a gate-shaped primary core 13, two control coils 14 and a strip-shaped permanent magnet 15,

[0032] The opening side of the gate-shaped primary iron core 13 is opposite to the secondary, and a control coil 14 is respectively wound on the two vertical sections of the gate-shaped primary iron core 13,

[0033] The gate-shaped primary iron core 13 is a symmetrical segmented structure, and the strip-shaped permanent magnet 15 is clamped between each segment of the gate-shaped primary iron core 13, and the connecting end fac...

specific Embodiment approach 2

[0038] Specific implementation mode two: the following combination figure 1 with figure 2 Describe this embodiment. This embodiment is a further description of Embodiment 1. The gate-shaped primary iron core 13 is a two-stage structure, each iron core is L-shaped, and the elongated permanent magnet 15 is clamped between the two L-shaped Between the iron cores, the elongated permanent magnets 15 are magnetized in parallel along the horizontal direction. Other components and connections are the same as those in Embodiment 1.

specific Embodiment approach 3

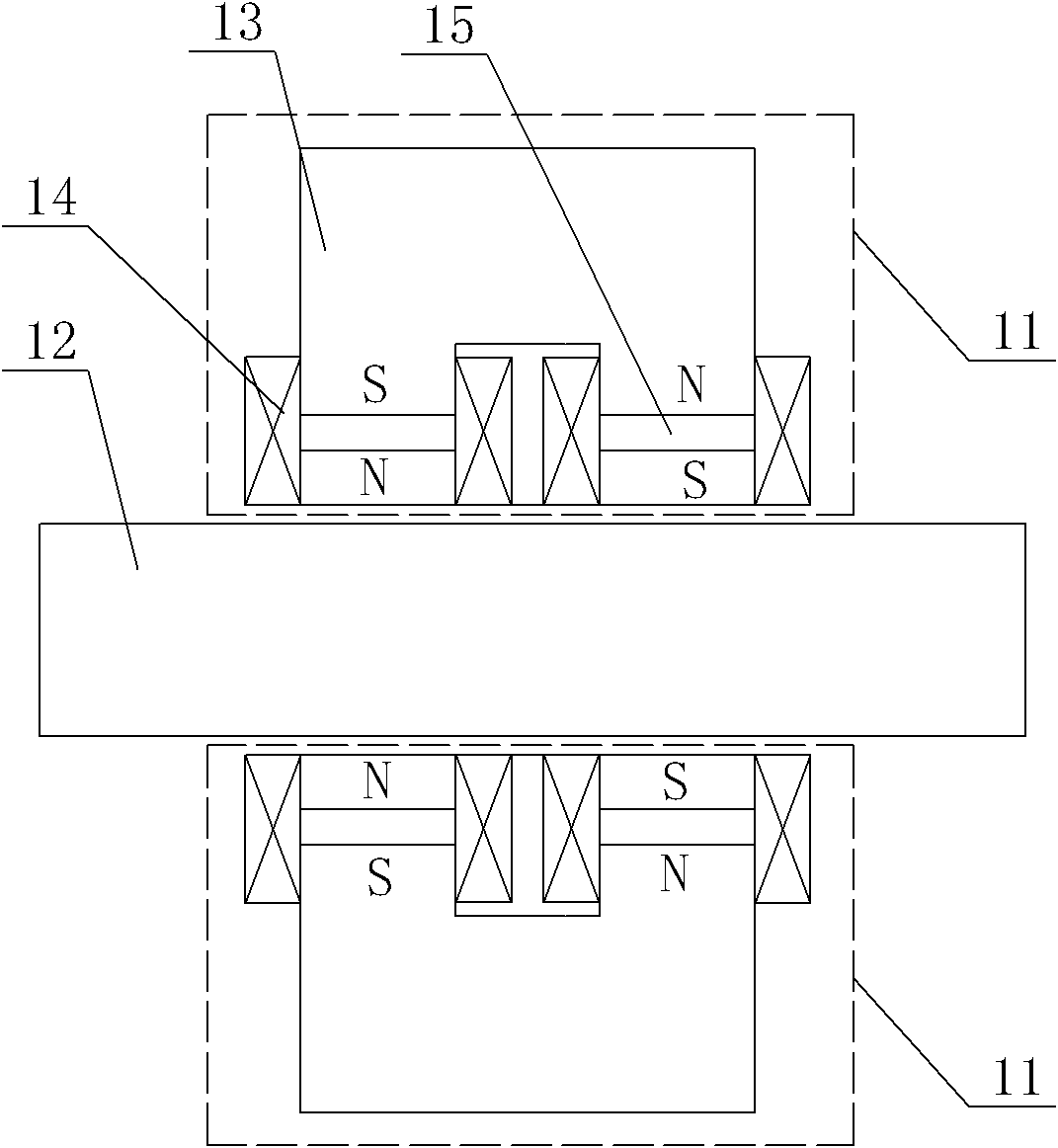

[0039] Specific implementation mode three: the following combination image 3 with Figure 4 Describe this embodiment, this embodiment is a further description of Embodiment 1: the gate-shaped primary iron core 13 is a three-section structure, and each vertical section wrapped around the control coil 14 is composed of two sections, and the two-section iron core A strip-shaped permanent magnet 15 is clamped therebetween, and the position of the strip-shaped permanent magnet 15 corresponds to the middle section of the wound control coil 14;

[0040] Each strip-shaped permanent magnet 15 is magnetized in parallel along the vertical direction, and the magnetization directions of the two strip-shaped permanent magnets 15 located on the same gate-shaped primary core 13 are opposite. Other components and connections are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com