Capacitor touch screen

A capacitive touch screen and electrode technology, which is applied in the direction of electrical digital data processing, instruments, and data processing input/output process, etc., can solve problems such as difficulty in freely setting film layers, limiting capacitance parameter design, increasing manufacturing costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

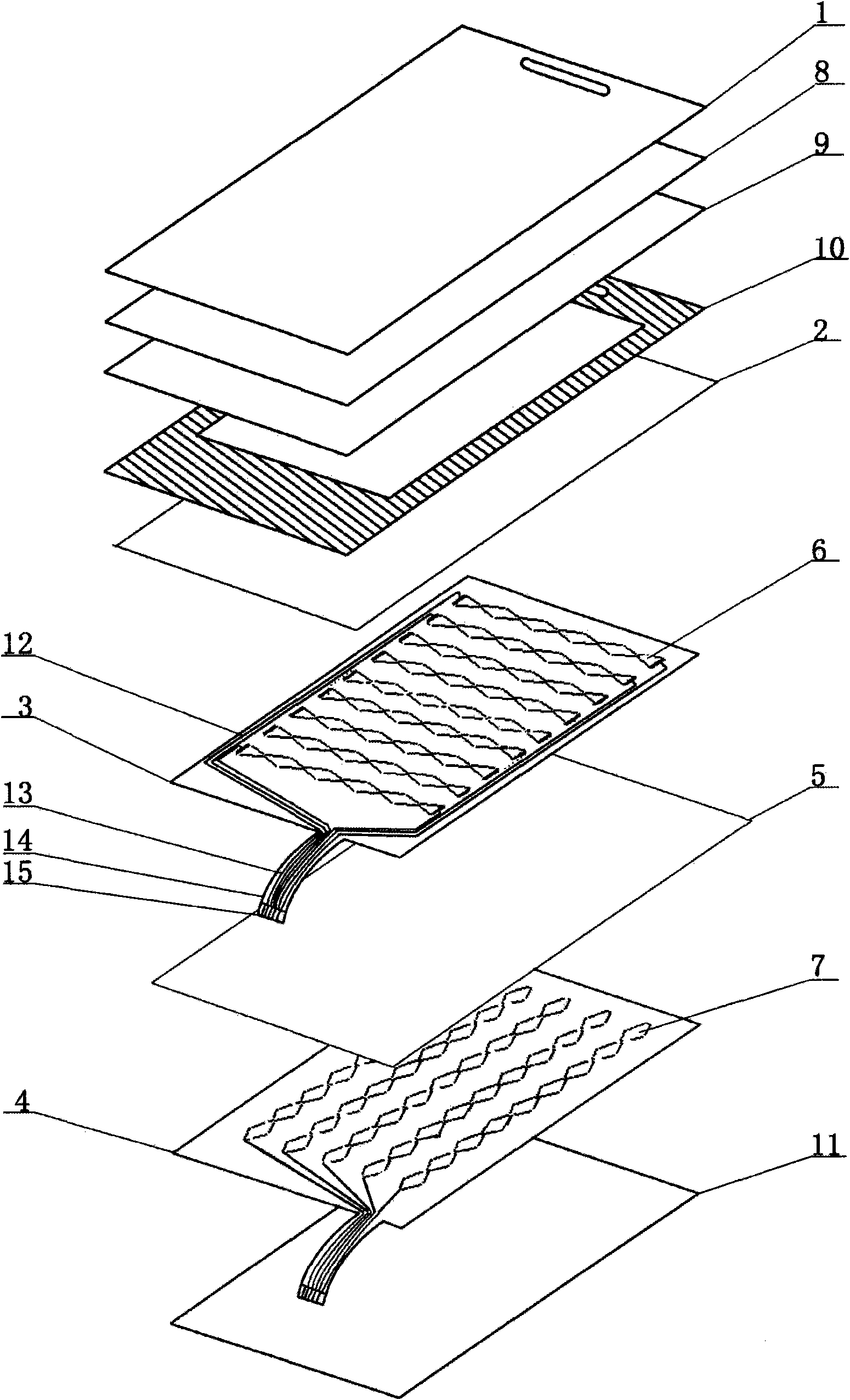

Method used

Image

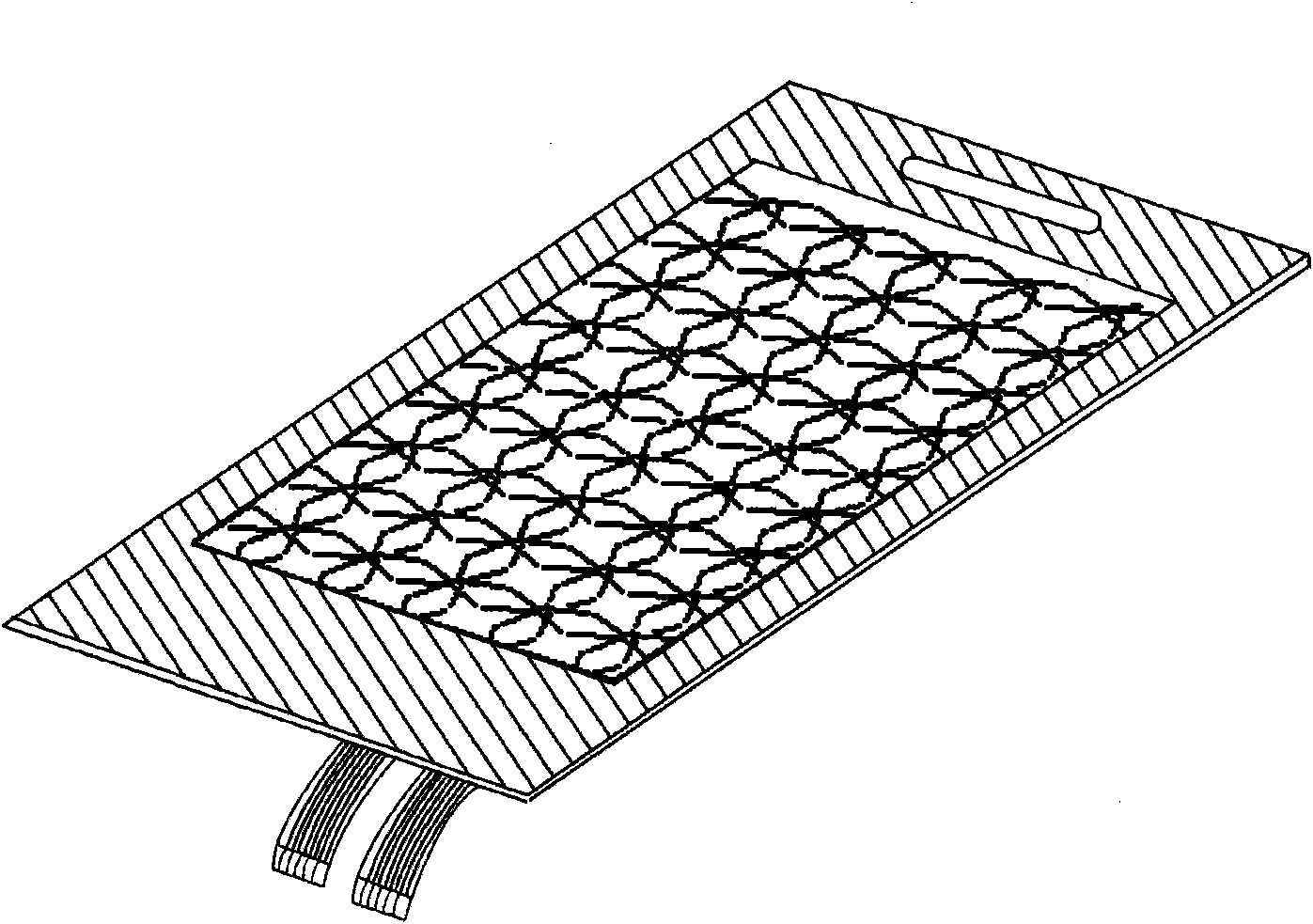

Examples

no. 3 approach

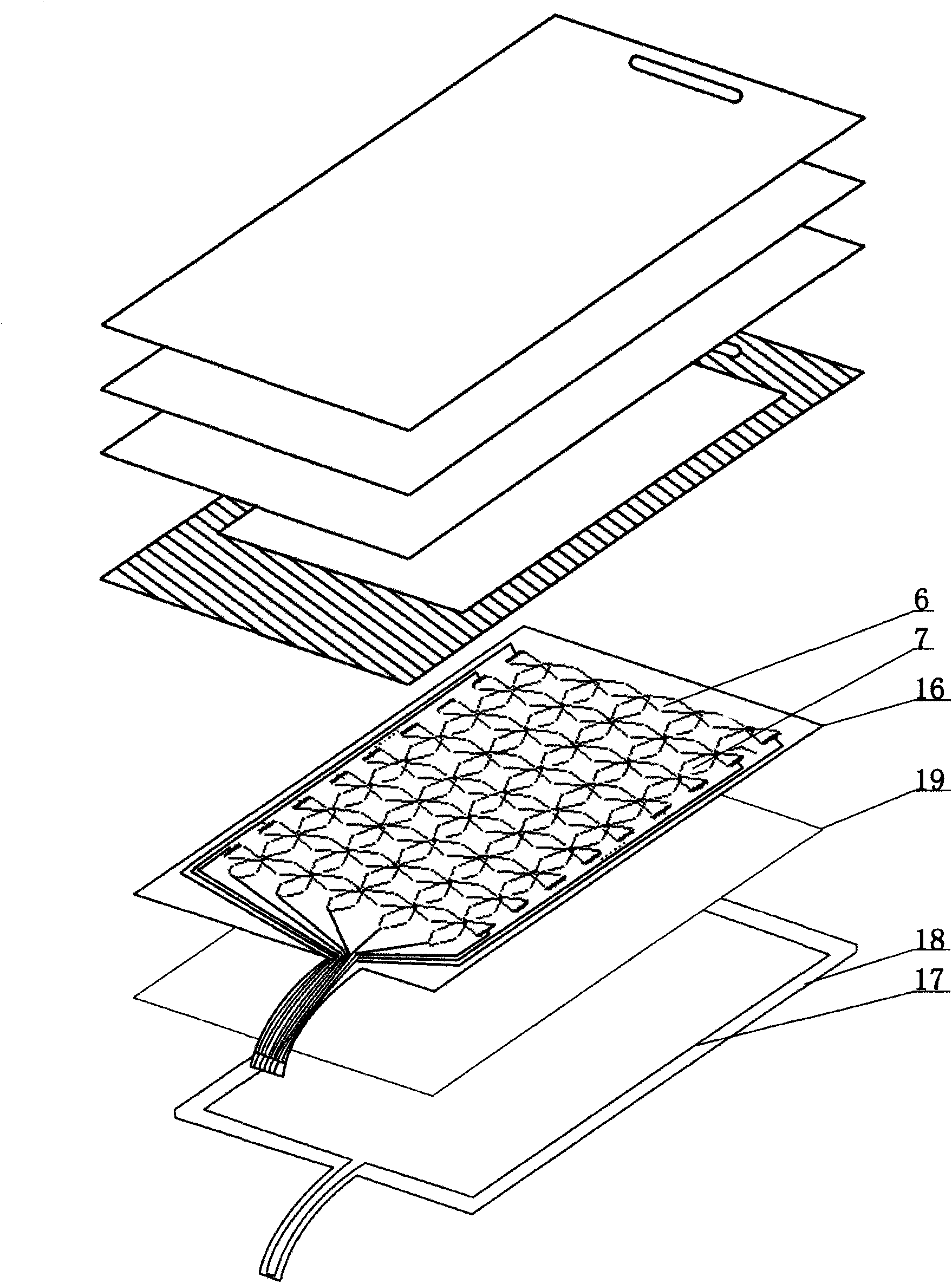

[0042]In the case that other parts are the same as the first embodiment, the difference is that: instead of setting the polarizing layer, retardation layer and optical compensation layer, the internal anti-reflection layer 20 is set on the inner side of the sensing electrode layer; there is no shielding Instead, the distance between the first sensing electrode 6 and the second sensing electrode 7 is designed to be 0.25mm to play a shielding role. By designing the distance between the first sensing electrode 6 and the second sensing electrode 7 to be 0.25 mm, the second sensing electrode 7 can be used as a shielding electrode layer, and the electrode support layer 16 can be used as a shielding insulating layer, which can shield most of the Interference from external signals at the bottom of the touch screen, so there is no need to additionally provide a shielding electrode layer and a corresponding shielding insulation layer, which simplifies the structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com