Nth-order shift register capable of increasing driving power and method thereof

A technology of shift register and driving capability, which is applied in the direction of static memory, digital memory information, instruments, etc., and can solve problems such as inability to charge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

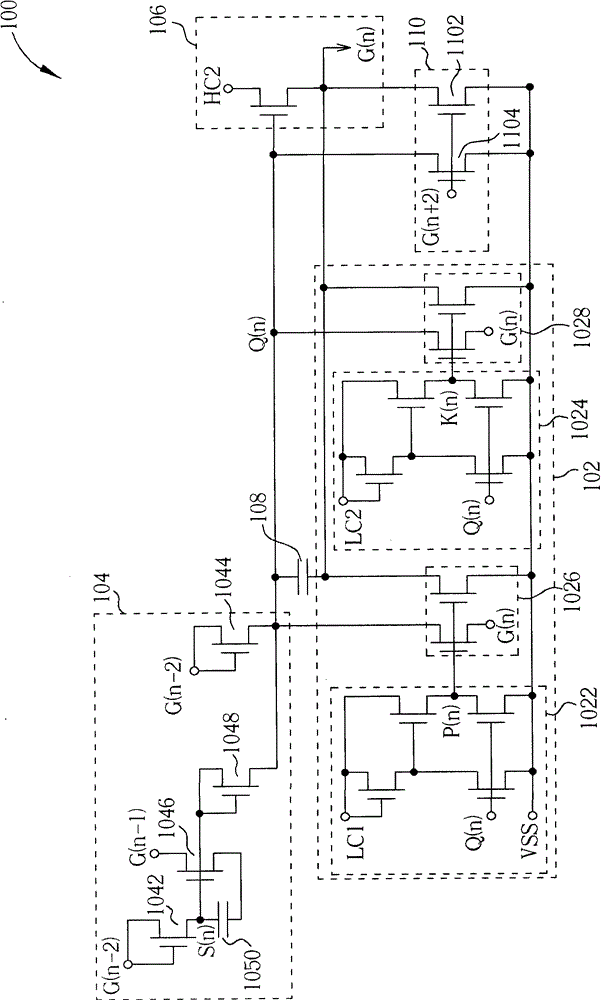

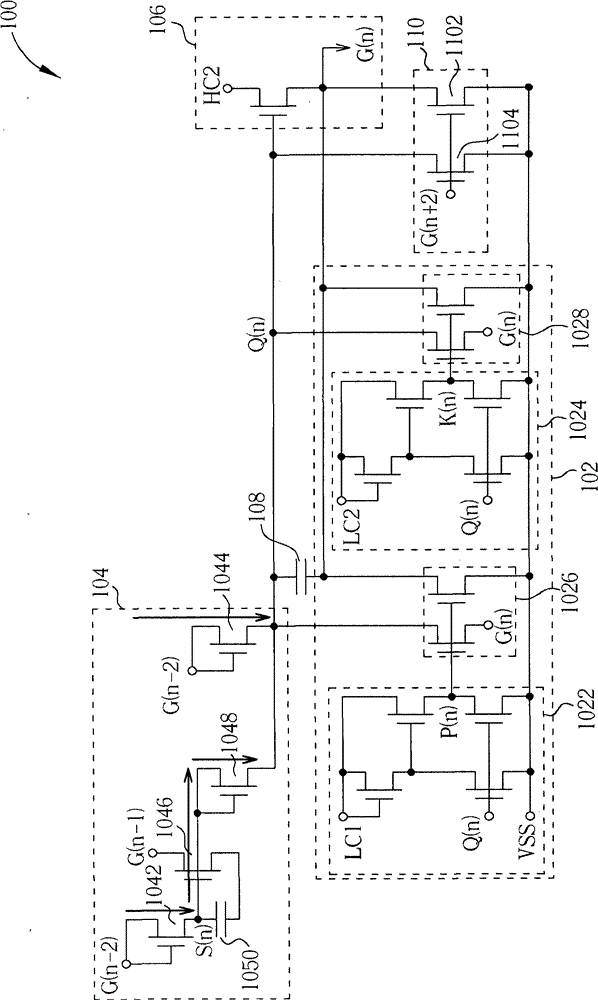

[0039] Please refer to figure 1 , figure 1 A schematic diagram of an n-th stage shift register 100 capable of increasing driving capability is illustrated for an embodiment of the present invention. The nth shift register 100 includes a pull-down circuit 102 , a pull-up circuit 104 , a driver circuit 106 , a first capacitor 108 and a key pull-down circuit 110 . The pull-down circuit 102 uses the potential of the first node Q(n) and the first low-frequency clock signal LC1 and the second low-frequency clock signal LC2 to pull down the potential of the first node Q(n) to the output node of the shift register 100 of the nth stage The potential of G(n) and the potential of the output node G(n) of the n-th shift register 100 are pulled down to the reference low potential VSS. The pull-up circuit 104 is coupled to the pull-down circuit 102, and uses the output signal G(n-2) of the n-2th stage shift register to pull up the potential of the first node Q(n) for the first time, and th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap