Variable-pitch servo driver with function of energy storage

A servo driver and functional technology, which is applied in the output power conversion device, the conversion of AC power input to AC power output, and the control of AC motor, etc., can solve the problem of undiscovered pitch servo drives, and the overall structure and control of the pitch system are complex. and other problems, to achieve the effect of compact structure, high reliability requirements and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

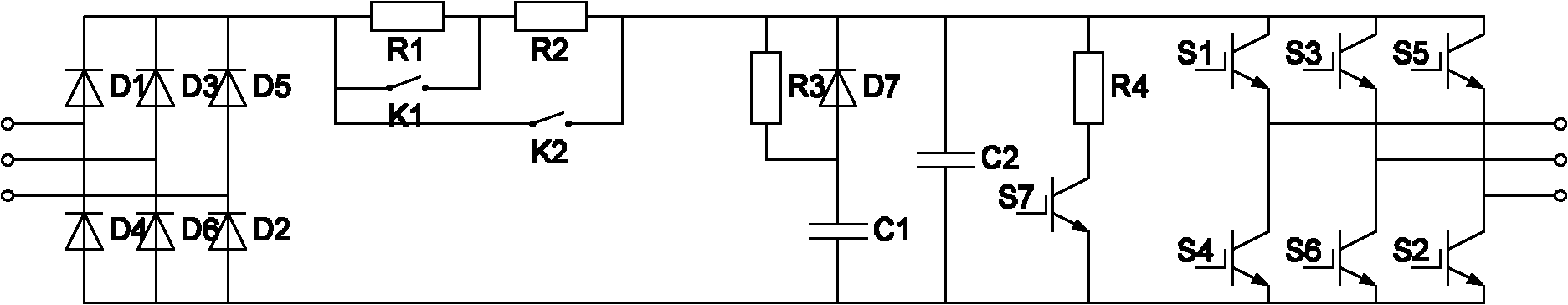

[0020] This embodiment is a 10kW electric servo pitch driver, the rated torque of the selected motor is 30Nm, and the rated speed is 2200rpm. In emergency feathering, the motor is required to run at a speed of 3000rpm and a torque of 30Nm for 10s. The entire servo driver can be powered off in the power grid Maintain normal operation for 3s.

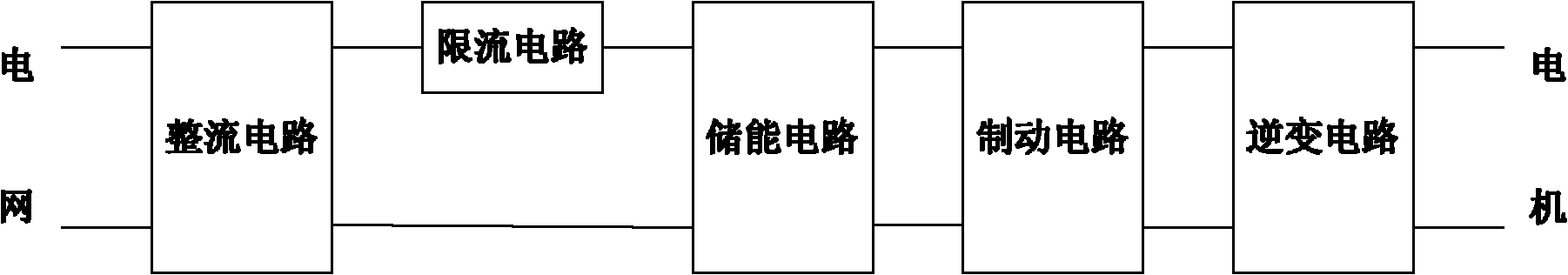

[0021] Such as figure 1 and figure 2 As shown, this embodiment includes: a rectification circuit, a current limiting circuit, an energy storage circuit, a braking circuit and an inverter circuit, wherein: the input terminal of the rectification circuit is connected to the power grid to transmit AC voltage, and an output terminal of the rectification circuit is connected to the current limiting circuit The input terminal of the circuit is connected to transmit DC voltage, the other output terminal of the rectifier circuit is connected to one input terminal of the energy storage circuit to transmit DC voltage, the output terminal of the c...

Embodiment 2

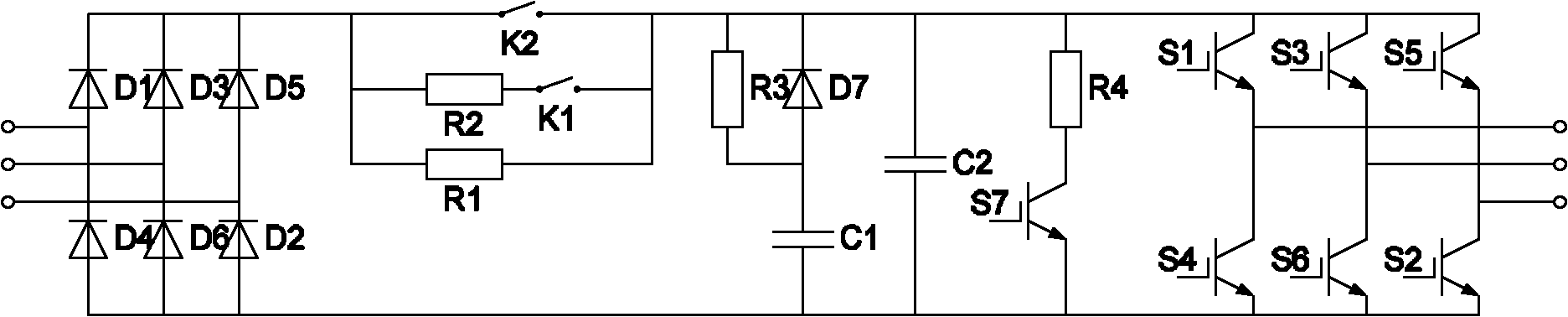

[0040] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that: the current limiting circuit includes: a first resistor R1, a second resistor R2, a first contactor K1 and a second contactor K2, wherein: the first resistor R1 One end of the second resistor R2, one end of the second contactor K2 are respectively connected to the positive output end of the rectifier circuit two by two, the other end of the second resistor R2 is connected to one end of the first contactor K1, and the second contactor The other end of K2, the other end of the first contactor K1, the other end of the first resistor R1 and an input end of the energy storage circuit are respectively connected in pairs.

[0041] In this embodiment, the resistance value of the first resistor R1 is 94 ohms, the resistance value of the second resistor R2 is 33 ohms, the rated voltage of the first contactor K1 and the second contactor K2 are both 600VDC, the first contactor K1 and The ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com