Large current deexcitation loop based on silicon controlled rectifier subject to multi-redundancy trigger of jumper

A trigger control and jumper technology, which is applied in the direction of controlling generators, control systems, emergency protection circuit devices, etc., can solve the problem of large-capacity generator sets with large demagnetization current, and a single thyristor jumper cannot meet the maximum demagnetization current. De-excitation requirements under magnetic working conditions, unreliable de-excitation method and other issues, to achieve the effect of high-current de-excitation reliability, high reliability, and protection safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

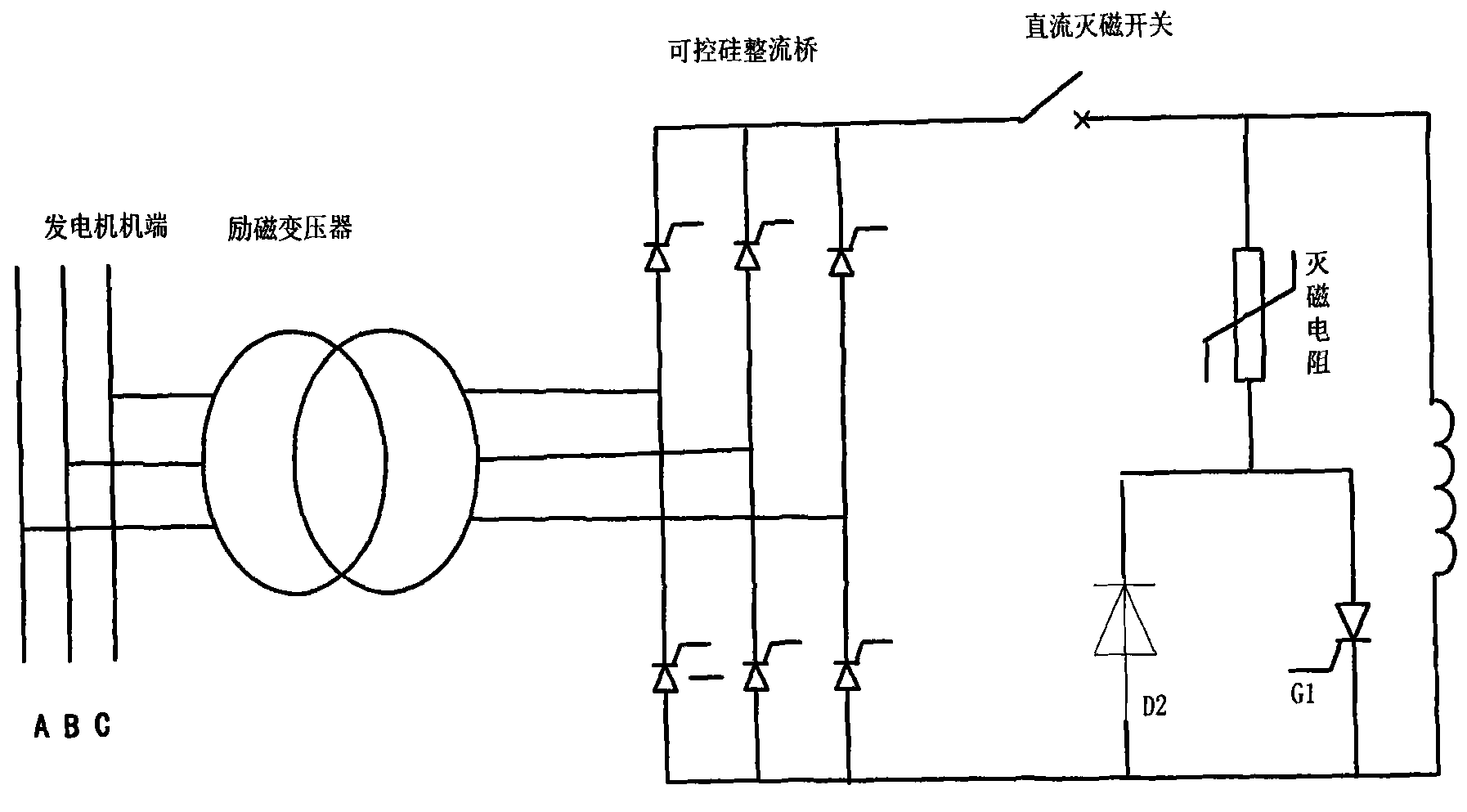

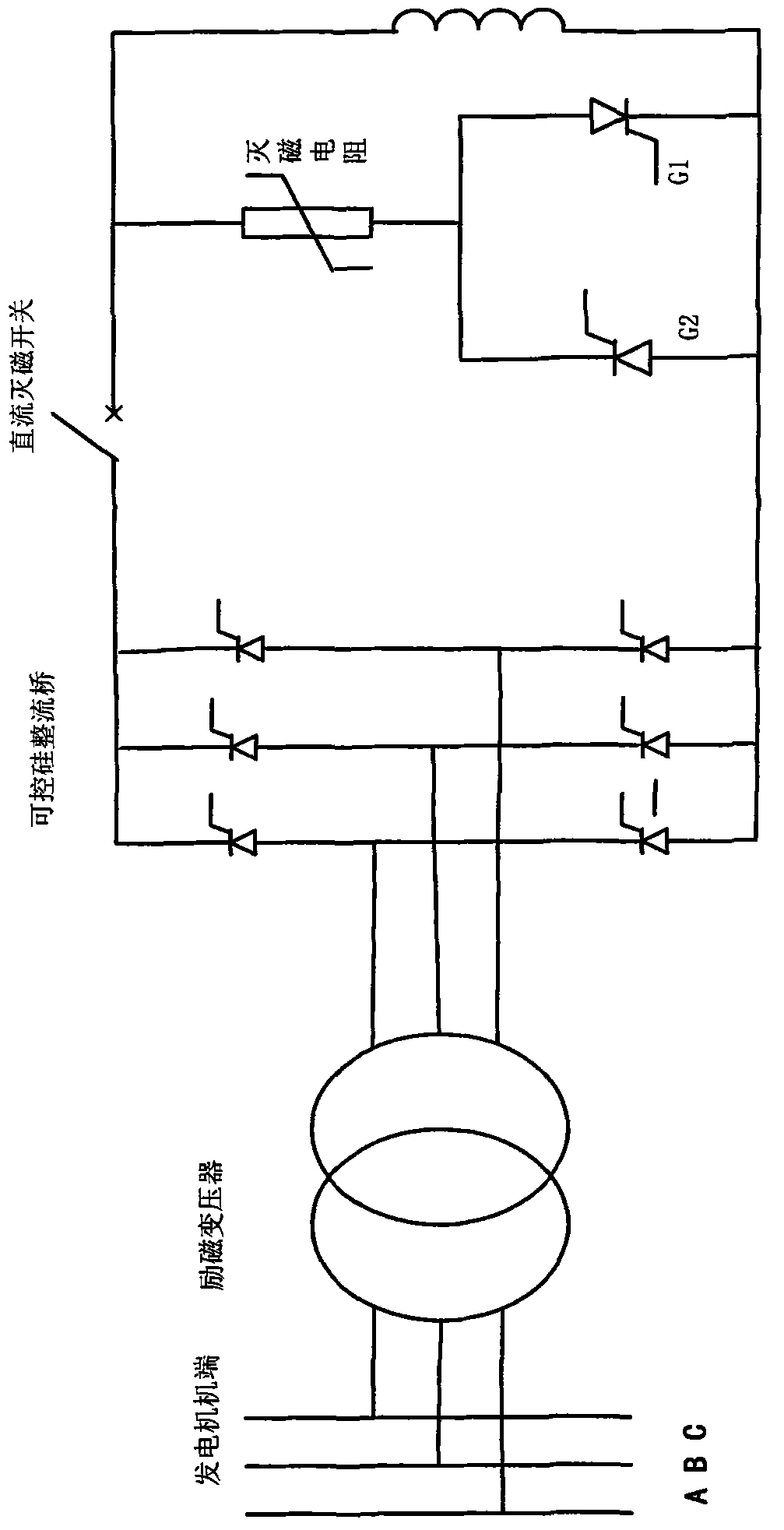

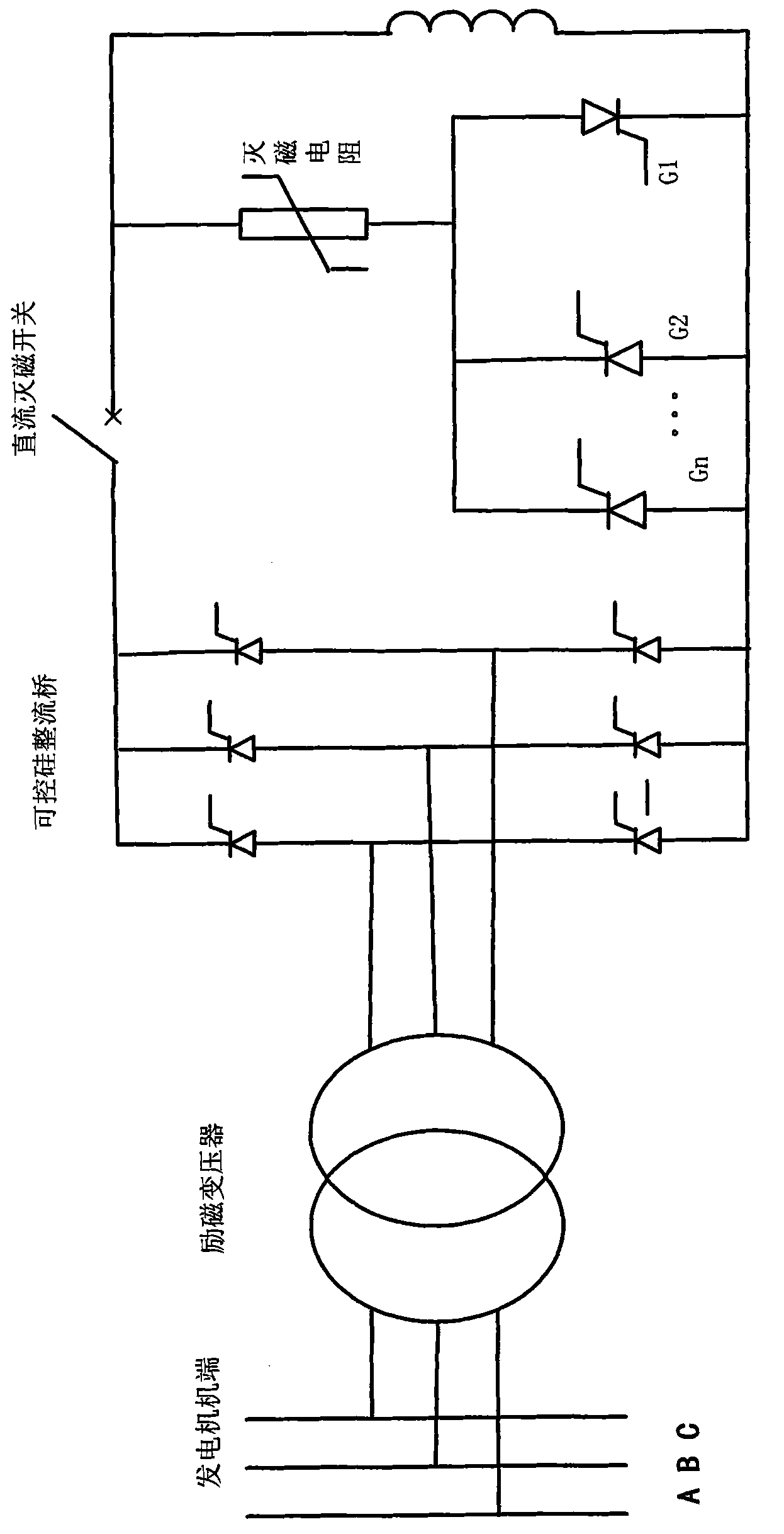

[0024] The present invention aims at the problem that the demagnetization current of large-capacity generator sets is too large, and a single thyristor cannot meet the requirements of safe and reliable demagnetization under the most serious working conditions. One or even multiple SCRs are connected in parallel to improve the flow capacity of the entire demagnetization circuit, that is, multiple SCR redundant demagnetization circuits. The basic characteristics of the de-excitation circuit are: first, multiple thyristors are connected in parallel in series with the non-linear resistance circuit in the de-excitation control circuit; second, the parallel thyristors use components of the same manufacturer and type, and It is very important to use high-parameter thyristor components as much as possible; thirdly, the characteristic parameters of each thyristor should be matched as well as possible, and it is best to confirm that the current sharing effect is good through relevant exp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com