Special high-frequency heater for hot drawing roller

A high-frequency heater and high-frequency heating technology, applied in the direction of induction heating, induction heating devices, etc., can solve the problems of easy burning of electric heating wires, large eddy currents, and high energy consumption, and achieve stable line control, fast heating speed, and no heating. easy burnout effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

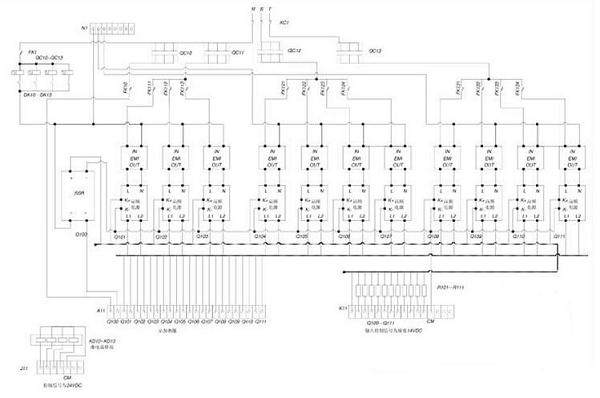

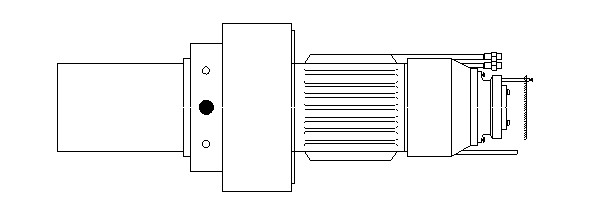

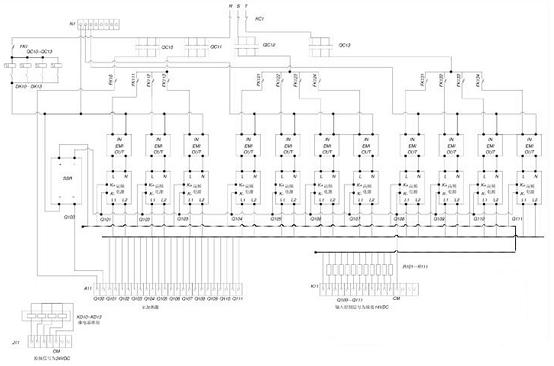

[0009] Embodiment 1: with reference to attached figure 1 and 2 . The high-frequency heater dedicated to the hot drafting roller includes a power frequency heater and a temperature controller. The coil in the power frequency heater is a high-frequency heating coil, which constitutes a high-frequency heater. The circuit of the temperature control appliance is provided with a high-frequency generating source, the input end of the high-frequency generating source inputs 50HZ / 220V power frequency, and the output end inputs 20KHZ high-frequency and is used for high-frequency heating in the high-frequency heater The coil is heated, that is, the output of the high-frequency generator is connected to the input of the high-frequency heater.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com