Method for homogenizing residual stress through vibration positioning

A residual stress and stress technology, applied in the field of residual stress vibration positioning homogenization, can solve the problems of long experimental period for obtaining aging process parameters, uncontrollable aging effect, blind operation and implementation, etc. Fast and effective processing, the effect of shortened cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

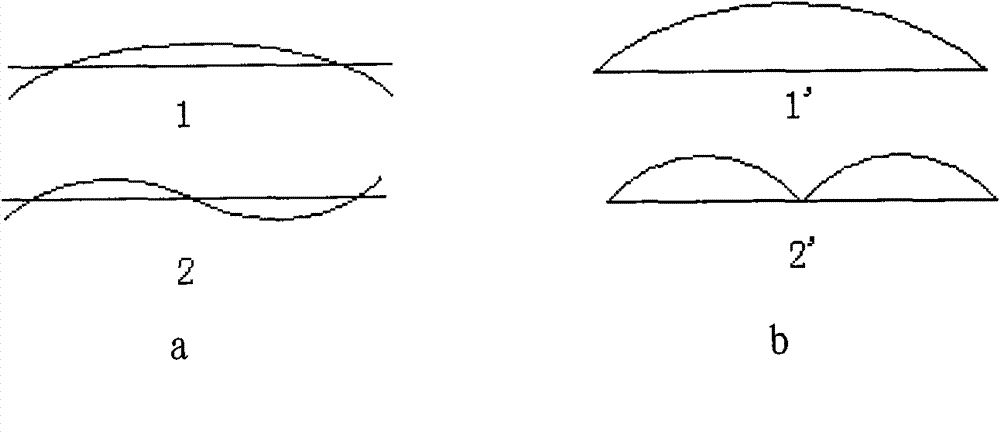

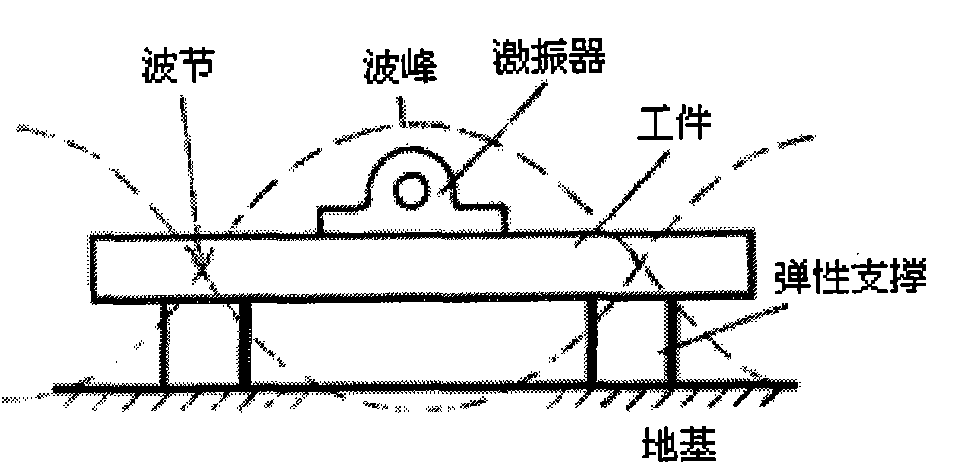

[0043] like figure 1 1 shown in a is the first-order mode shape of the slender beam, and 2 is the second-order mode shape of the slender beam, such as figure 1 1' shown in b is the first-order modal stress distribution, and 2' is the second-order modal stress distribution. Different frequencies correspond to different mode shapes, and different mode shapes correspond to different dynamic stress fields. Focus on eliminating residual stress in different parts . The bending stress in the middle of the first-order vibration mode is the largest, and the focus is to eliminate the residual stress in the middle of the beam; the peak value of the bending stress in the second-order vibration mode moves to 1 / 4 of the beam, and the focus is to eliminate the residual stress in this part, and eliminate the residual stress in different parts by selecting different vibration modes. Residual Stress.

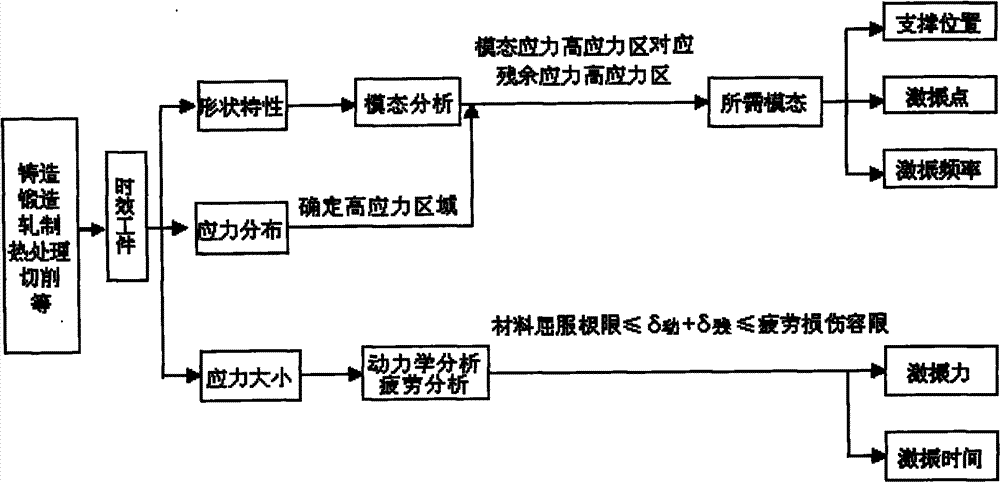

[0044] like figure 2As shown, it is the method of reducing and homogenizing residual stre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com