Crystallizer capable of controlling crystallization and nucleation process through ultrasonic wave

A technology of nucleation process and crystallization control, which is applied in the directions of sugar crystallization, crystallization separation, oscillation crystallization, etc. It can solve the problems of difficult installation and low energy density, and achieve the effect of simple energy input control, high cost and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

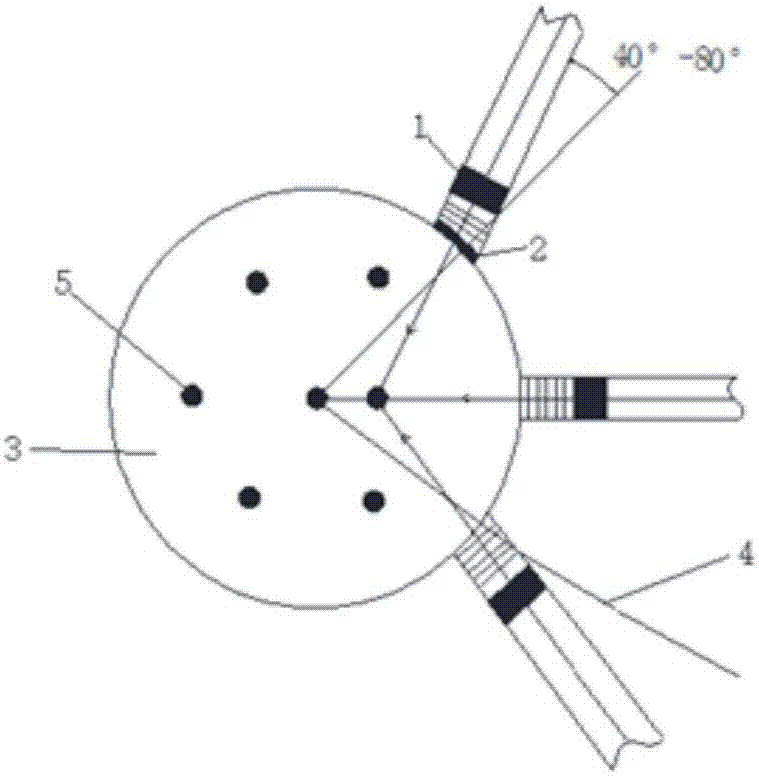

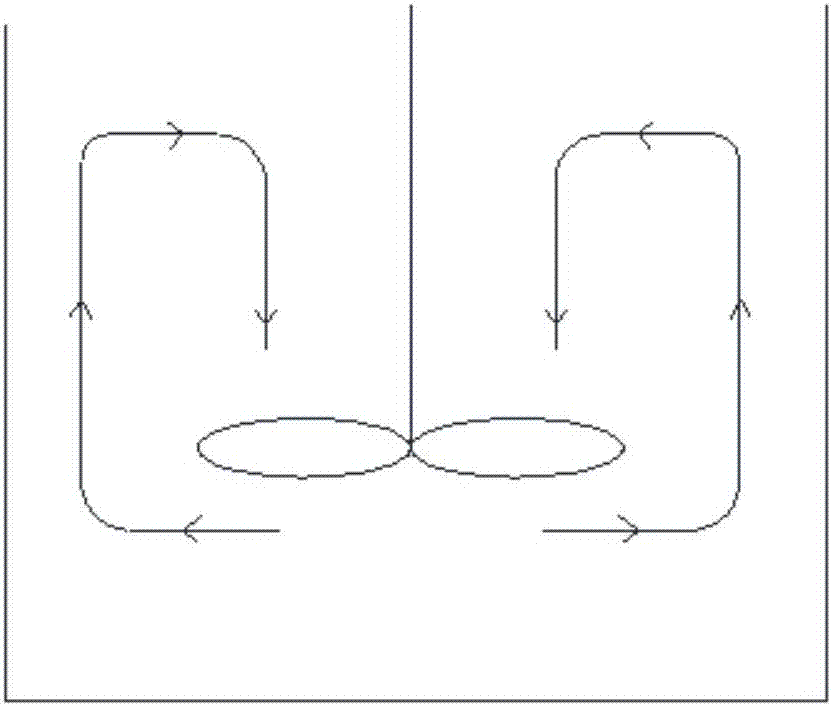

Method used

Image

Examples

Embodiment 1

[0035] In this embodiment, sucrose is used as the solute, water is used as the solvent, and methanol is used as the eluent.

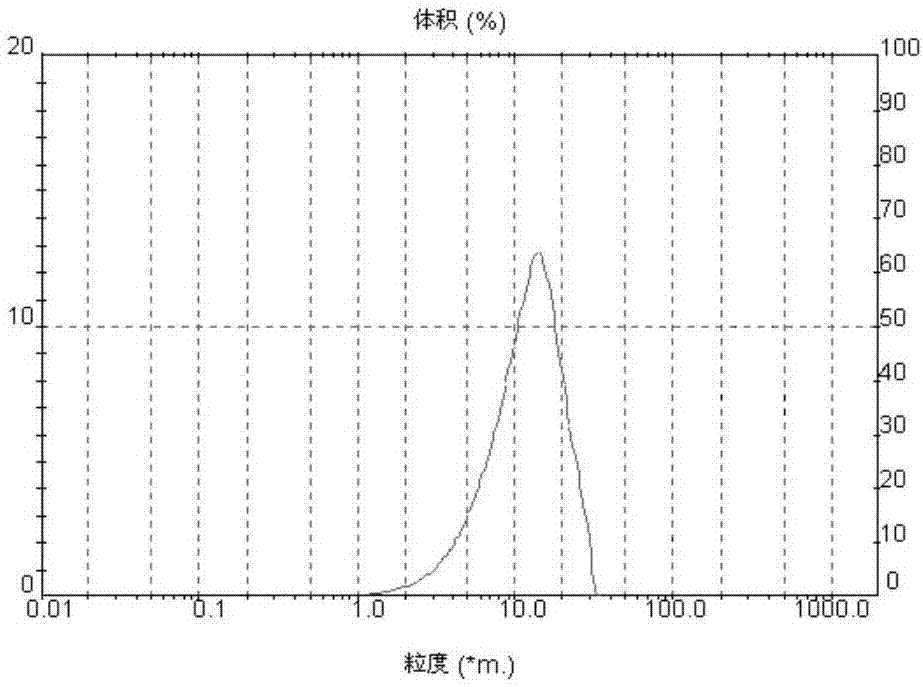

[0036] The results of particle size analysis of the seeds induced by ultrasound and the seeds produced by grinding are as follows: image 3 and 4 As shown, it can be seen from the figure that the main particle size and particle size distribution range of the sucrose seed crystals induced by ultrasound are far superior to those produced by grinding, so it is easier to produce crystals with uniform particle size distribution. Seed crystals are easier to disperse in the crystallization mother liquor container. Therefore, when the volume of the crystallization module can ensure uniform mixing, there is no problem of dispersion of the ultrasonically induced seeds.

Embodiment 2

[0038] Two sets of ultrasonic crystallizers are installed on the 100-liter crystallization mother liquor container, each group contains three 60W ultrasonic generators, and the generated ultrasonic waves are focused on the circulation area of the crystallization mother liquor. In the crystallization mother liquid container, water is used as solvent and methanol is used as eluent to produce sucrose crystals. Dissolve 2.6 kg of sucrose in 15 kg of water. Add 80 kg of methanol at a uniform speed to carry out intermittent elution and crystallization.

[0039] When the ultrasonic nucleation inducer is not turned on, the crystal nuclei are precipitated when 19 kg of methanol is added. Stop feeding methanol for half an hour and resume feeding. After adding all 80 kg of methanol, the crystallization system continues to stir for 40 minutes, and filter , drain the mother liquor, wash the crystals with methanol at room temperature, and conduct particle size analysis. The particle size...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com