Jute spinning method

A technology of jute and jute fiber, which is applied in the direction of yarn, textiles, papermaking, fiber treatment, etc., can solve the problems of low length and strength of jute fiber, low count of jute fiber, insufficient softening, etc., to improve softness and reduce fiber length The difference rate, the effect of increasing the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

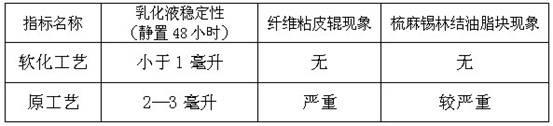

[0006] First soften the jute fiber with a softening solution, pour the softening solution on the jute fiber, and then ferment in a pile. After softening, proceed to the combing step. After combing and re-spinning. The components and weight percent of the softening liquid composition used for softening treatment are emulsifier 1.5%, soft sesame oil 23.5%, water 75%, wherein, the components and weight percent of the emulsifier are alcohol polyoxyethylene ether sodium sulfate 4%, sodium dodecylbenzenesulfonate 4%, sodium lauryl sulfate 0.5%, alkyldiethanolamine 0.8%, softener 1.5%, sodium hydroxide 1.5%, sodium chloride 1.2%, water 86.5%. Preferably, 15% (weight percent) softening solution is poured on 85% (weight percent) jute.

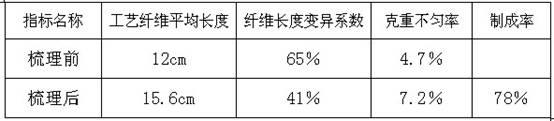

[0007] In the combing step, the softened jute fiber is first combed; the softened jute fiber is also combed by a ramie comber;

[0008] In the spinning step, the jute fibers after the above softening and combing treatments are subjected to sizing we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com