Compact high-pressure plunger variable double pump

A high-pressure column and compact technology, which is applied in the field of plunger oil pumps, to achieve the effects of compact overall structure, reduced weight, and reduced overall volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

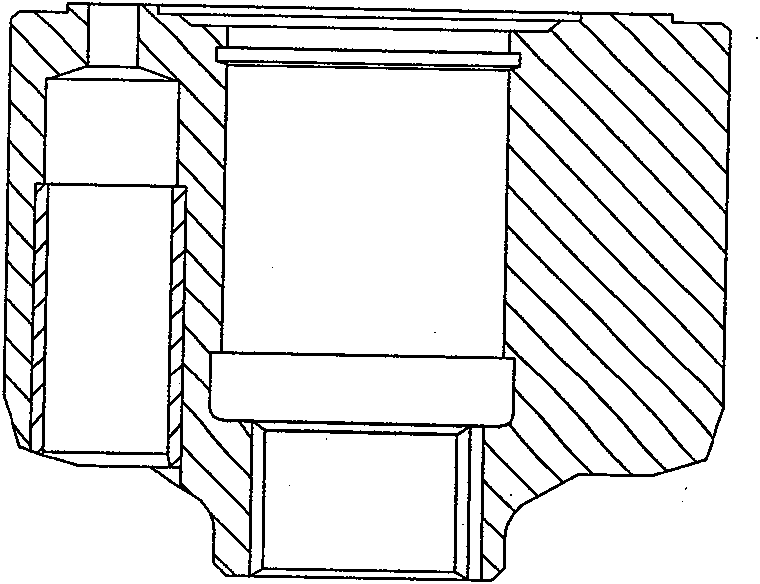

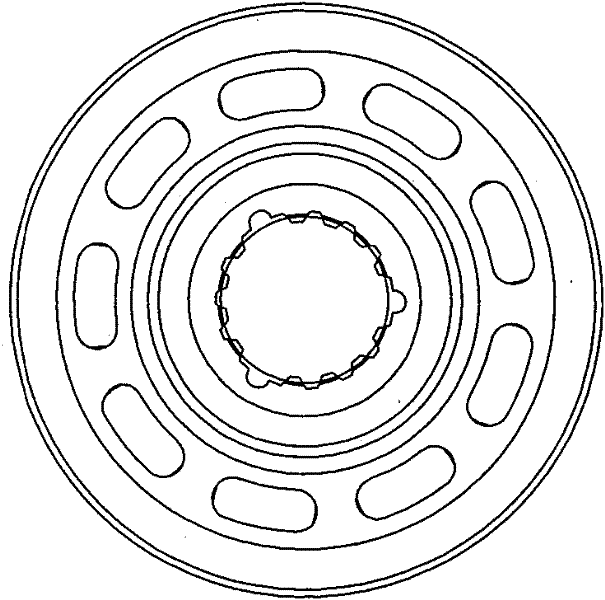

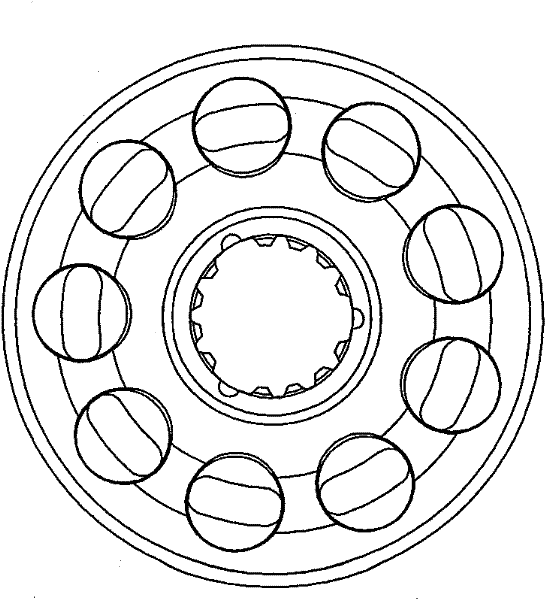

[0035] like Figure 1 to Figure 4a As shown, the symbol numbers are as follows: transmission shaft 1, large bearing 2, swash plate 3, housing 4, return plate 5, plunger shoe assembly 6, ball head body 61, cylinder body 7, spline hole 71, column Plug hole 72, distribution plate 8, oil suction ring groove 81, oil outlet ring groove 82, small bearing 9, positioning pin 10, rear cover 11, coupling sleeve 12, second valve sleeve 13, second valve core 14, first Valve sleeve 15, first spool 16, drive ring 17, adjustment spring 18, end cover 19, variable displacement piston 20, dial block 21, adjustment rod body 22, compression spring 23.

[0036] According to the embodiment of the present invention, a compact high-pressure plunger variable variable double pump includes a fixedly matched housing 4 and a rear cover 11. The inner cavity of the housing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com