Controllable self-clamping SensorFET composite vertical power device

A technology of power devices and power converters, applied in the electronic field, can solve problems such as device temperature rise and inability to discharge avalanche energy

- Summary

- Abstract

- Description

- Claims

- Application Information

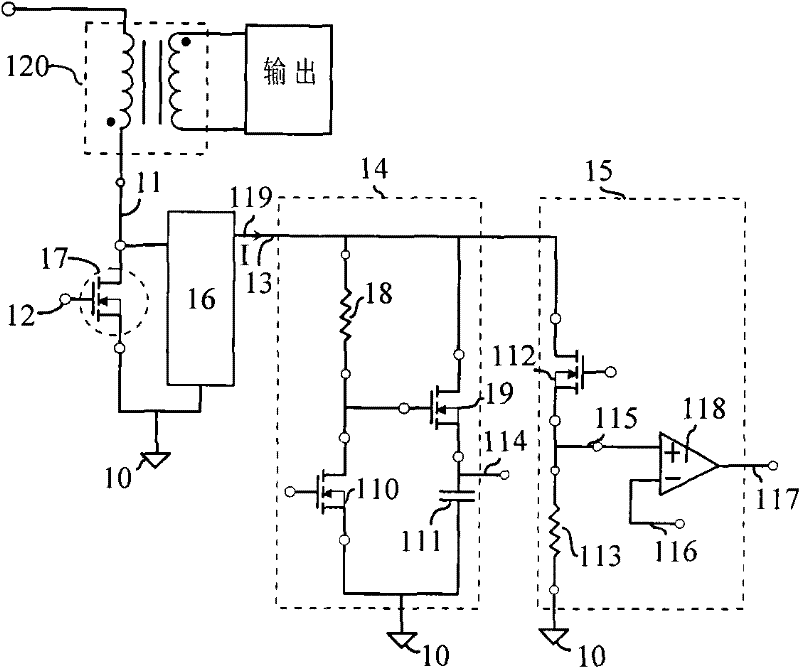

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

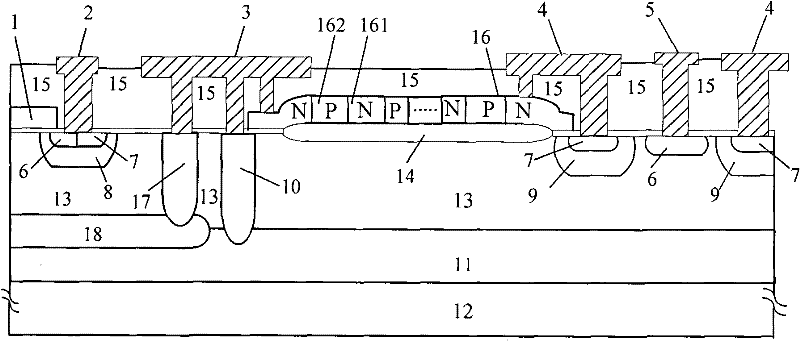

[0024] A controllable self-clamping SensorFET compound vertical power device, such as image 3 As shown, it includes a main switching tube of a power converter and a SensorFET device; the main switching tube and the SensorFET device of the power converter are integrated on the same P-type substrate 11 .

[0025] The SensorFET device is a vertical structure, including: P-type substrate 12, N - The drift region 13 is located on the P-type substrate 12 and the N - N between the drift region 13 + Buried layer 11; one located at N - In the drift region 13, one end is connected to the metal anode 3, and the other end extends into the N + Deep N-type contact region 10 of buried layer 11; one located at N - The N connected to the metal cathode electrode 5 in the drift region 13 + Region 6; by the deep N-type contact region 10, N + Buried layer 11, N - The N where the drift region 13 is connected to the metal cathode electrode 5 + Area 6 constitutes charging and current detecti...

specific Embodiment approach 2

[0028] A controllable self-clamping SensorFET compound vertical power device, such as image 3 As shown, it includes a main switching tube of a power converter and a SensorFET device; the main switching tube and the SensorFET device of the power converter are integrated on the same P-type substrate 11 .

[0029] The SensorFET device is a vertical structure, including: P-type substrate 12, N - The drift region 13 is located on the P-type substrate 12 and the N - N between the drift region 13 + Buried layer 11; one located at N - In the drift region 13, one end is connected to the metal anode 3, and the other end extends into the N + Deep N-type contact region 10 of buried layer 11; one located at N - The N connected to the metal cathode electrode 5 in the drift region 13 + Region 6; by the deep N-type contact region 10, N + Buried layer 11, N - The N where the drift region 13 is connected to the metal cathode electrode 5 + Area 6 constitutes charging and current detecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com