Hot air drying method of PVA fibers and drying ovens

A technology of hot air drying and drying oven, which is applied in the direction of artificial filament cleaning/drying, etc. It can solve the problems that restrict the expansion of fiber application fields, the appearance of fiber products is slightly yellow, and the fluctuation of dispersion is large, so as to achieve the guarantee of dispersion index and scale The effect of benefit improvement and manufacturing cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

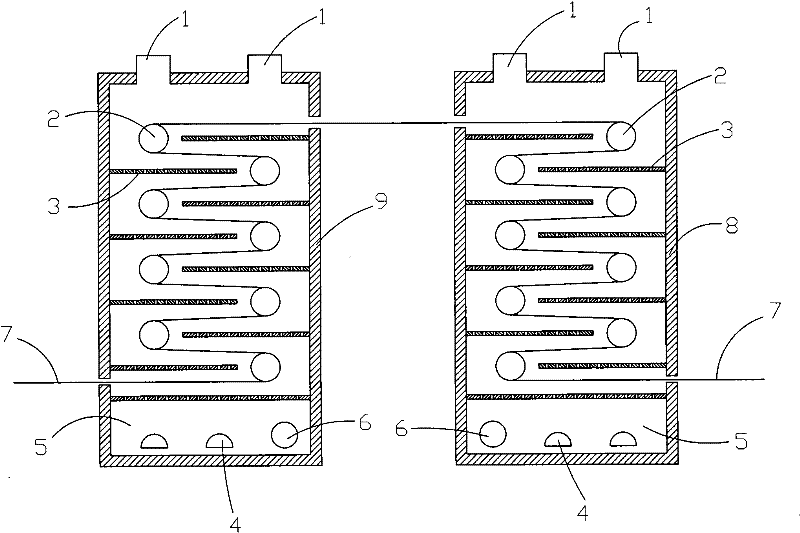

[0032] Specific implementation mode, first use the drawing ribbon to pass through the rollers in the oven to guide it for use. After each section of the oven is drawn, the neutralized water-washed tow is received, and the liquid is squeezed in the oil bath and then connected to the inlet drawing ribbon of the first-stage drying oven. Knot in the looper, start the drive roller to run, and pour out the ribbon from the outlet of the preheated hot air oven until the tow comes out. Then insert the tow into the inlet lead looper of the extension hot air oven, start the roller drive, and pour the tow at the outlet of the cooling roller.

[0033] After the threading is finished, the tow is reshaped so that the thickness of the tow is uniformly entered from the first-stage drying oven and runs between the rollers of each section of the oven.

[0034] Turn on the natural gas burner or hot air chamber and hot air circulation machine. The hot air rises from the combustion chamber or the hot ai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com