Vibration pile driving hammer with manipulation functions of multiple degrees of freedom

A degree of freedom, pile hammer technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of high labor intensity, long preparation time, and difficulty in holding long piles, so as to improve construction efficiency and reduce Construction cost and effect of quick pile grabbing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The implementation of the patent of the present invention will be further explained below in conjunction with the accompanying drawings.

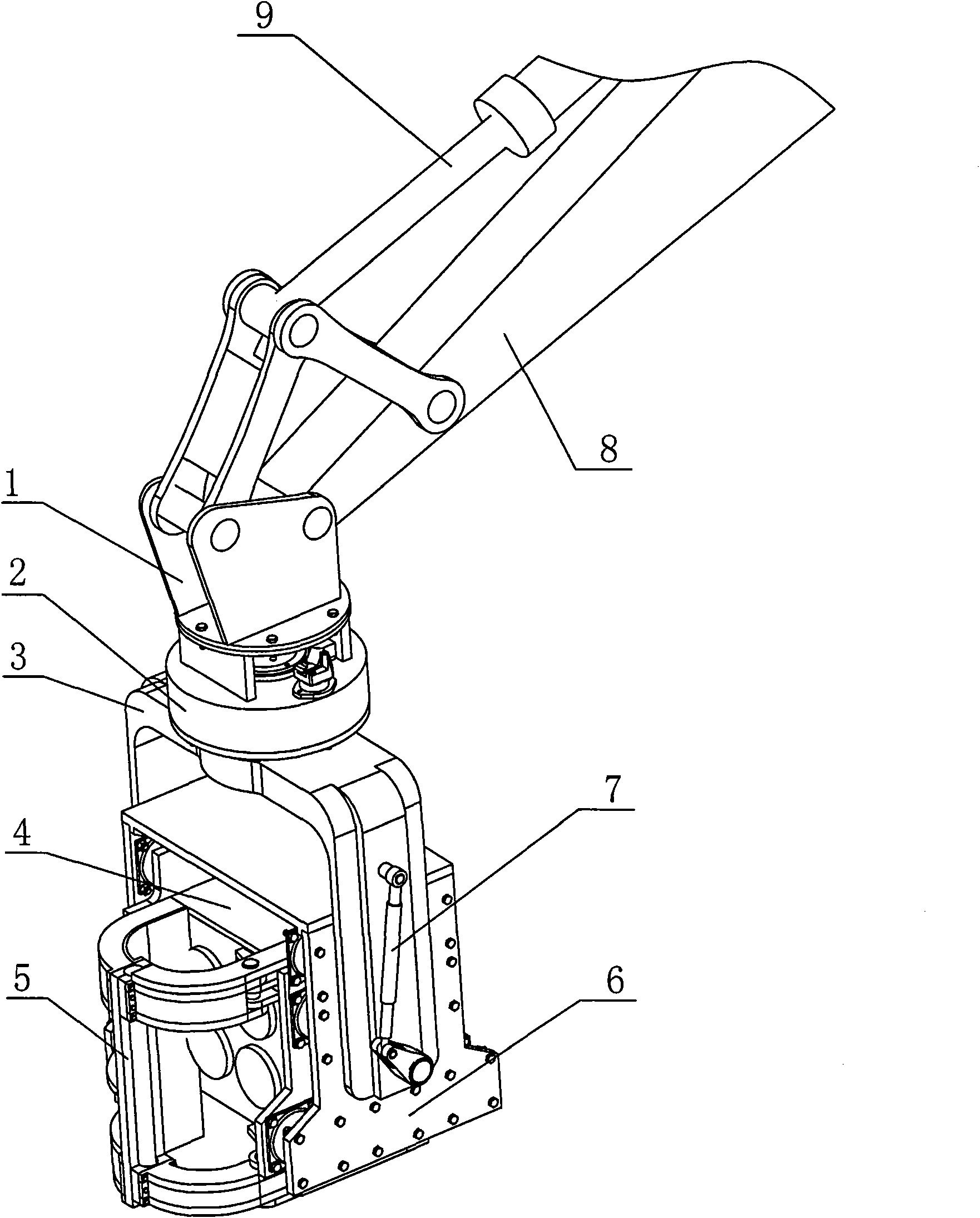

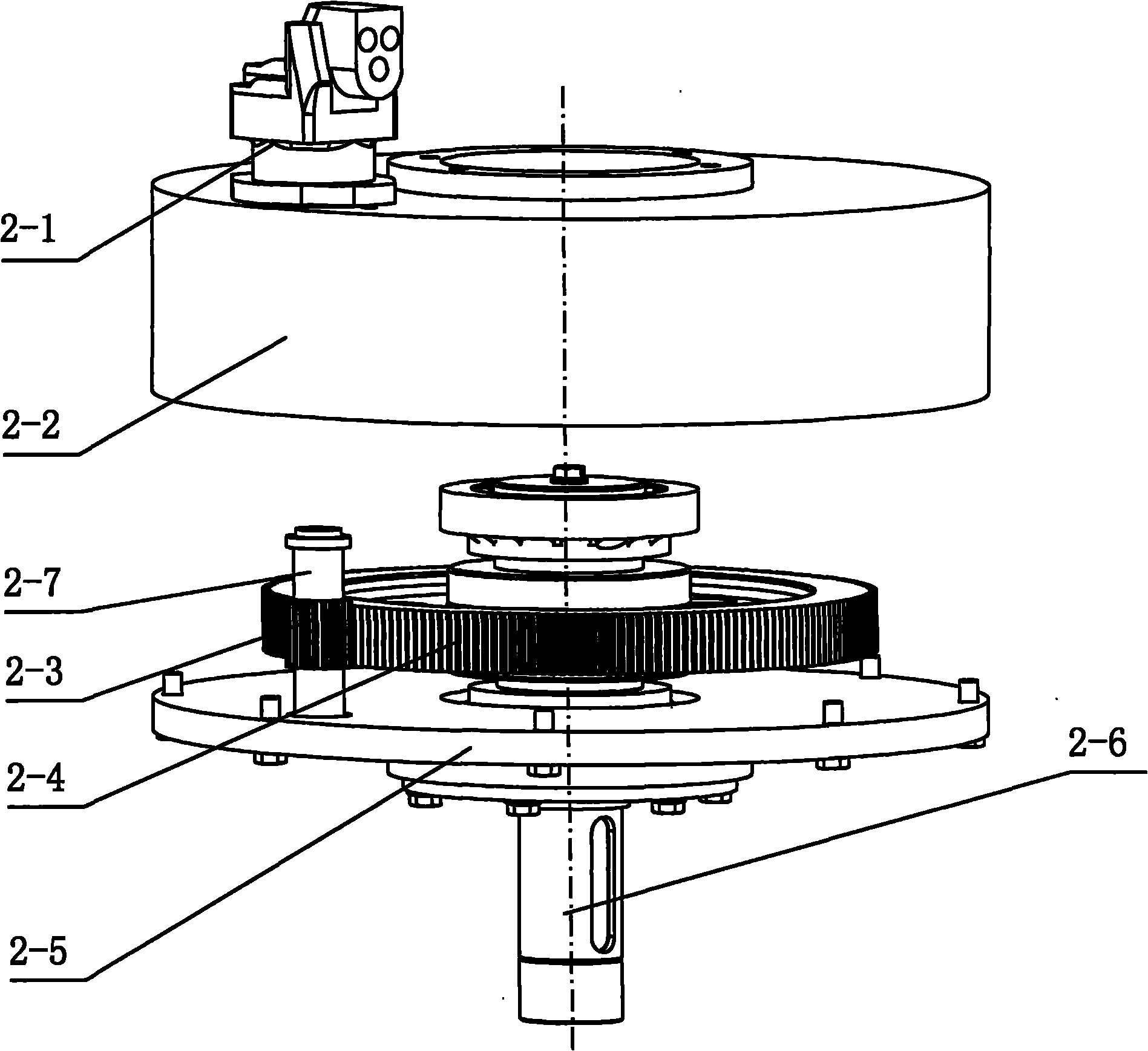

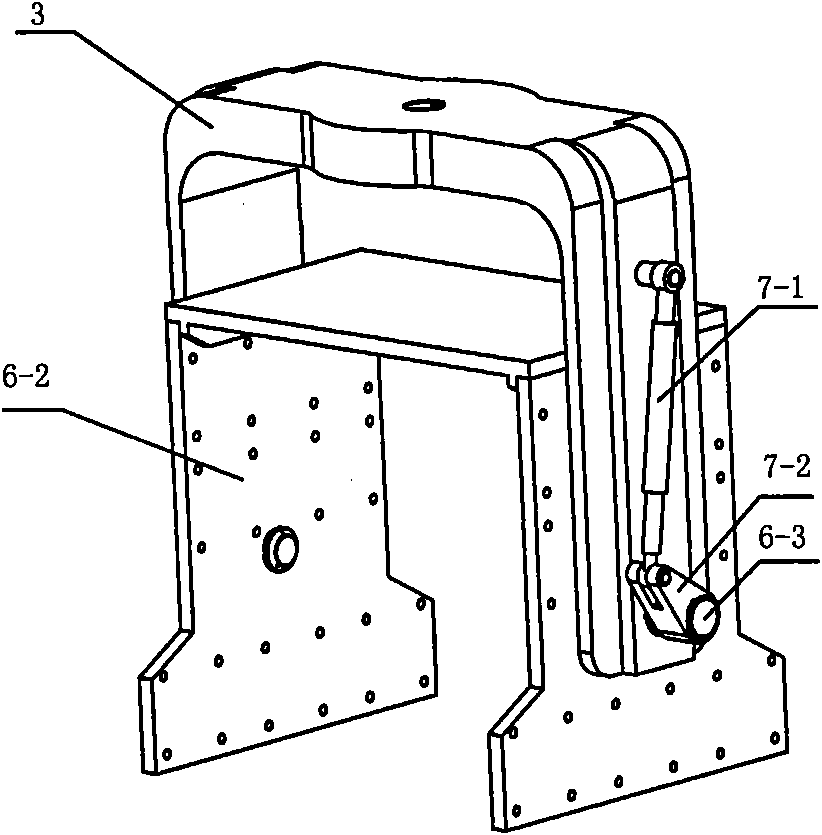

[0021] The invention patent can be passed figure 1 The structure shown is implemented: the vibratory piling hammer with multi-degree-of-freedom manipulation function includes a lifting connecting plate 1, a horizontal slewing mechanism 2, a hanger 3, a vibration exciter 4, a clamping device 5, a shock absorption device 6 and a vertical The swing mechanism 7 is composed of the lifting connecting plate 1 and the horizontal slewing mechanism 2. The horizontal slewing mechanism 2 is connected with the hanger 3 by a rotating pair, which can drive the hanger 3 to rotate 360° in the horizontal plane, and the hanger 3 is reduced by The vibration device 6 is connected to the vibration exciter 4, and the clamping device 5 is installed on the vibration exciter 4; the multi-degree-of-freedom control function of the vibratory piling hammer is compose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com