Thermoplastic polyurethane resin composition for plated dual molding, dual-molded article for plating, plated dual-molded article, and their production methods

A thermoplastic polyurethane and resin composition technology, applied in coating, liquid chemical plating, metal material coating process, etc., can solve the problems of unclear characteristics, such as the relationship between plating treatment resistance and resistance, and achieve the effect of inhibiting discoloration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、2 and comparative example 1~3

[0067]

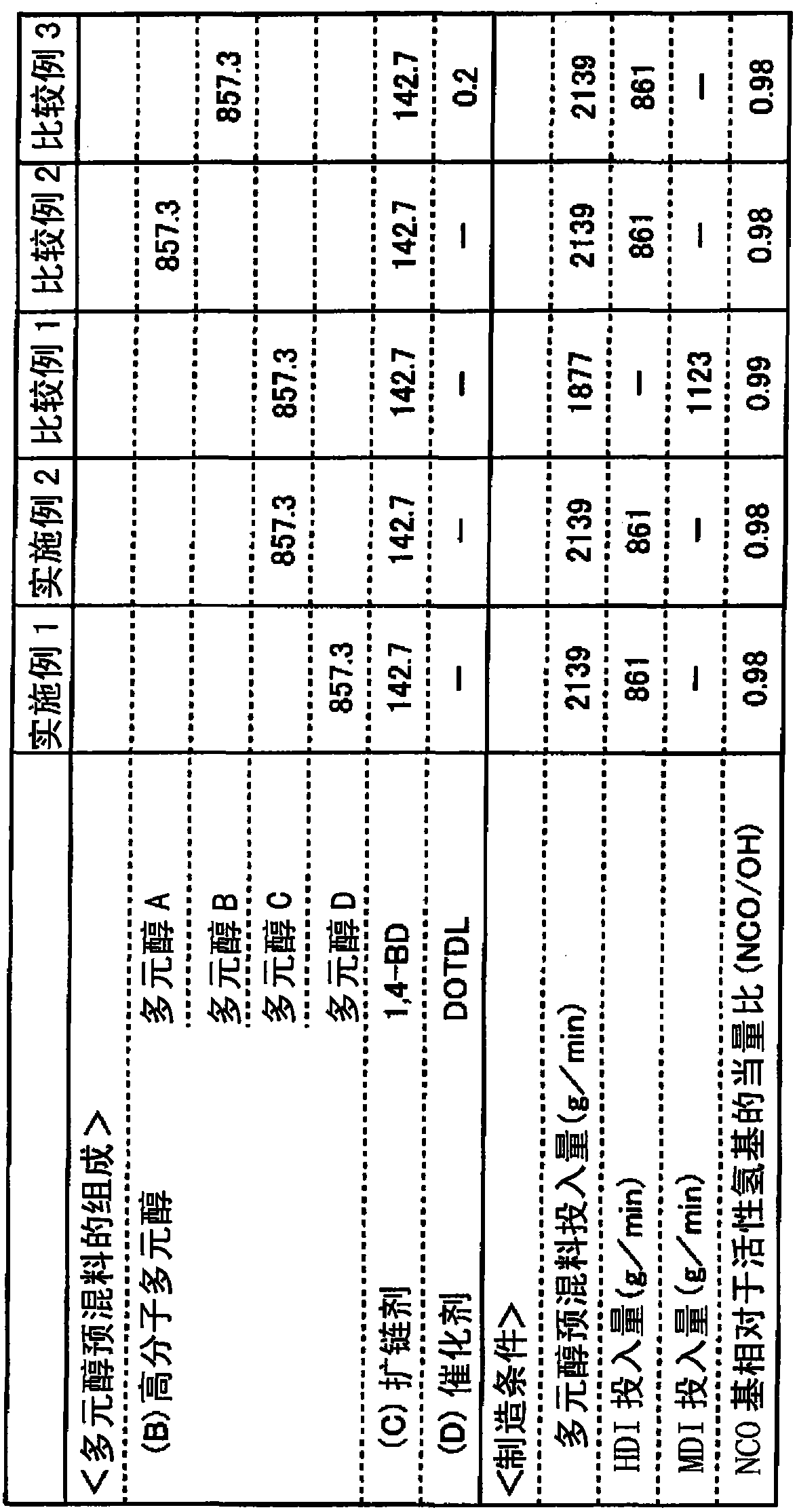

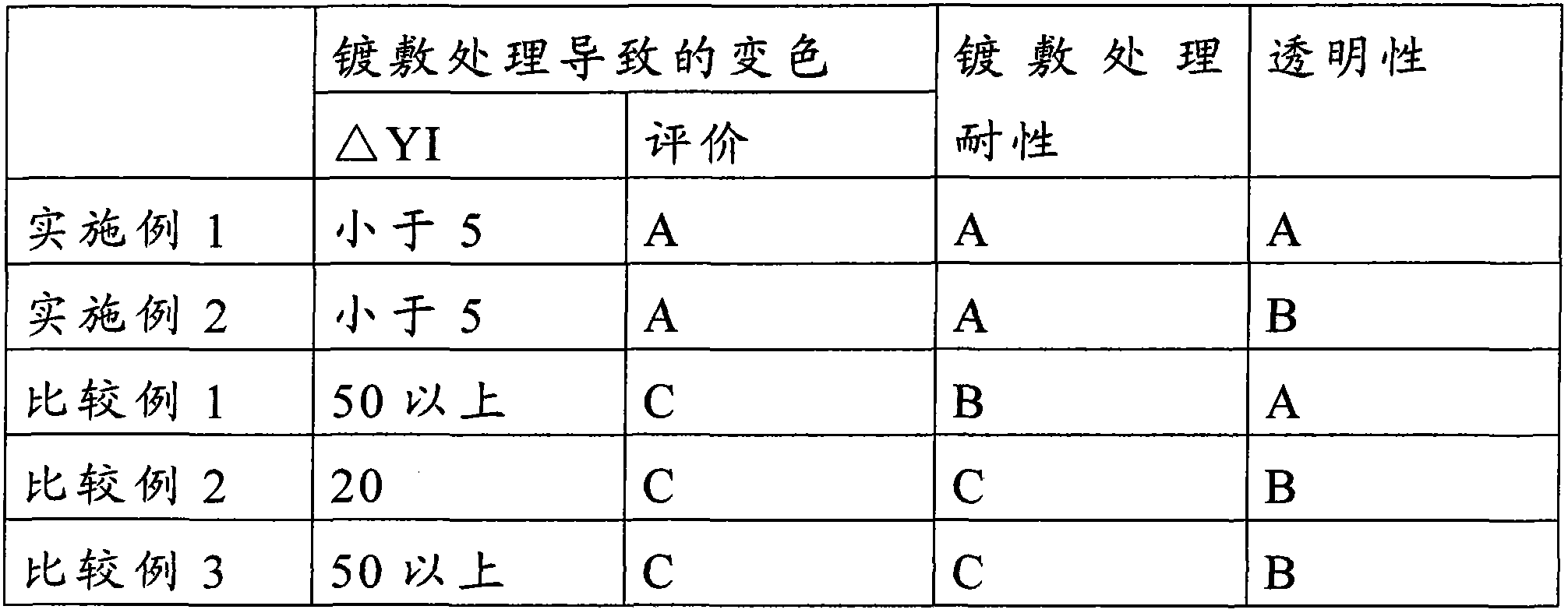

[0068] In Example 1, a thermoplastic polyurethane resin composition was obtained in the following manner. That is, 857.3 parts of polyol D and 142.7 parts of 1,4-BD were added to a mixing tank, followed by mixing, thereby obtaining a polyol premix. The temperature of the resulting polyol premix was then adjusted to 75°C. On the other hand, HDI was charged in another mixing tank, and then the temperature was adjusted so that the temperature was 50°C.

[0069] Next, the polyol premix and HDI were charged into a twin-screw extruder (manufactured by Ikegai Co., Ltd.). In addition, the temperatures in the vicinity of the hopper of the twin-screw extruder, the middle portion, and the front end were adjusted to 160° C., 180° C., and 200° C., respectively. Then with the input amount of polyol premixed material is 2139g / min, the input amount of HDI is the condition of 861g / min to add these raw materials continuously from the hopper mouth of twin-screw extruder, eject molte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com