White curable composition for optical semiconductor device, molded article for optical semiconductor device and optical semiconductor device

A technology of optical semiconductor device and curable composition, which is applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device parts, semiconductor devices, etc., to achieve the effects of not easy to reduce quality, suppress discoloration, and improve adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Method used

Image

Examples

Embodiment 1~18 and comparative example 1~8

[0160]Each component shown in the following Tables 1 and 2 was blended in the compounding amounts shown in the following Tables 1 and 2 (the compounding unit is parts by weight), and mixed with a mixer (LABOPLASTOMILL R-60, manufactured by Toyo Seiki Co., Ltd.) for 15 minutes to obtain a kneaded product.

[0161] (Evaluation)

[0162] (1) PCT resistance characteristics

[0163] The obtained kneaded product was heat-treated at 40° C. for 30 hours to be cured. The solidified kneaded product is pulverized, and a sheet-like product (curable composition) is formed.

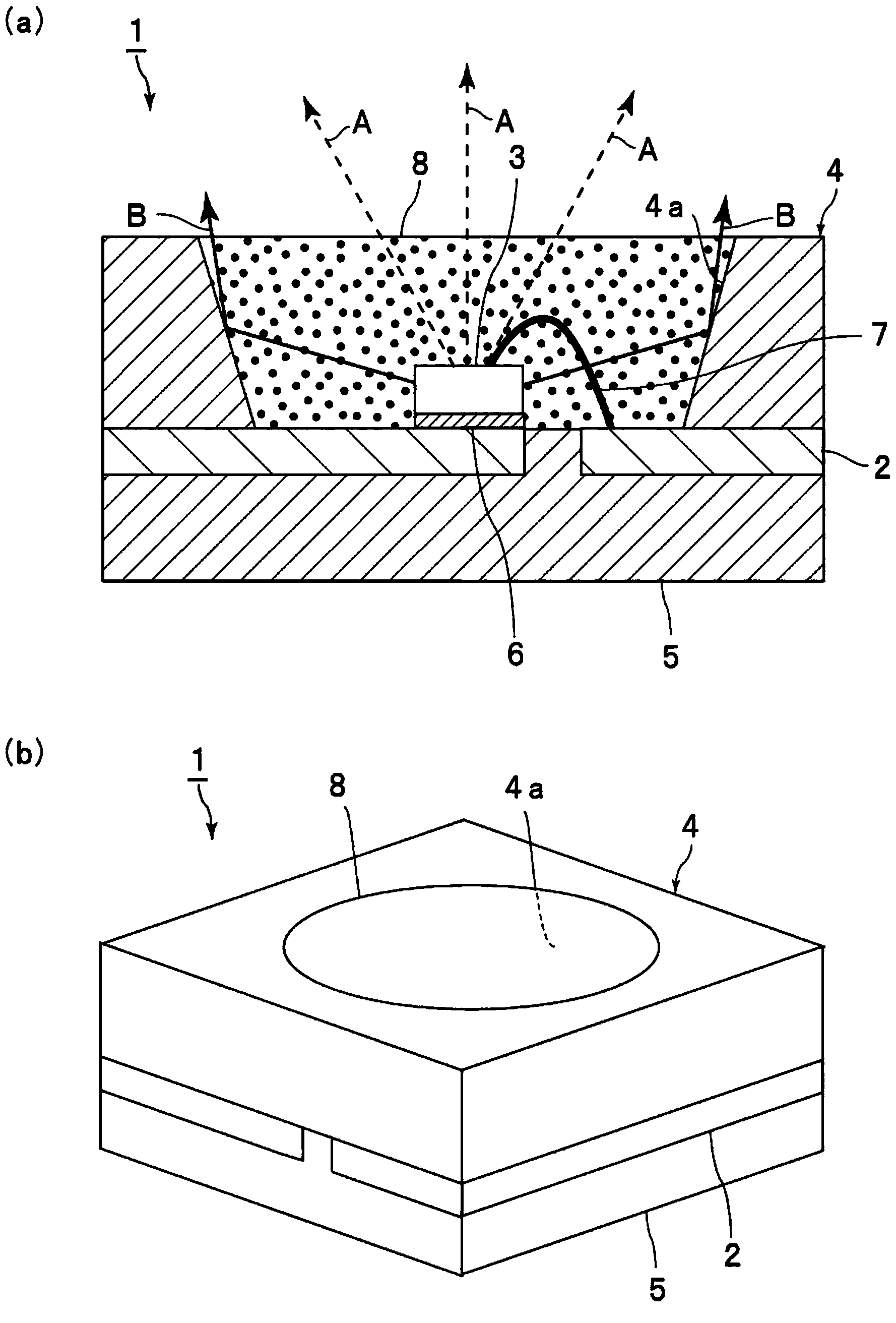

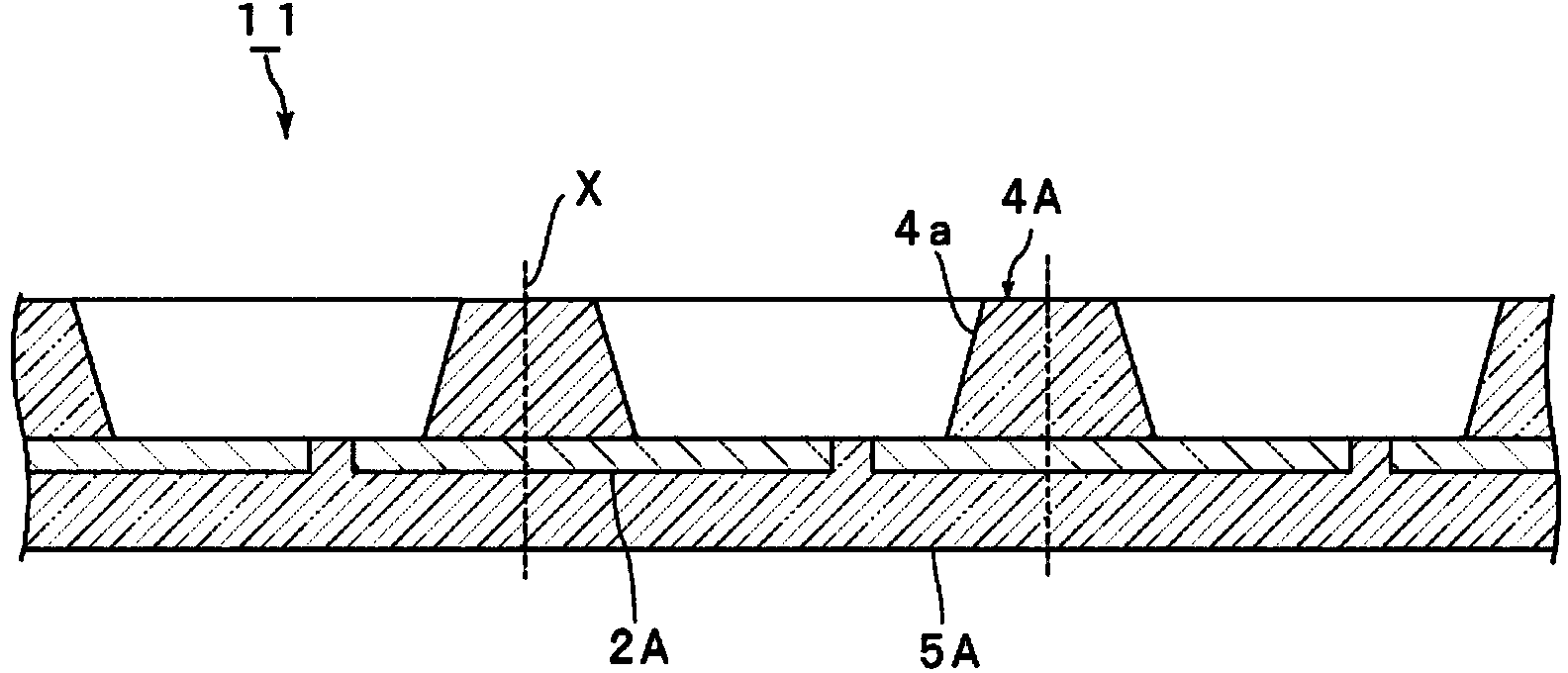

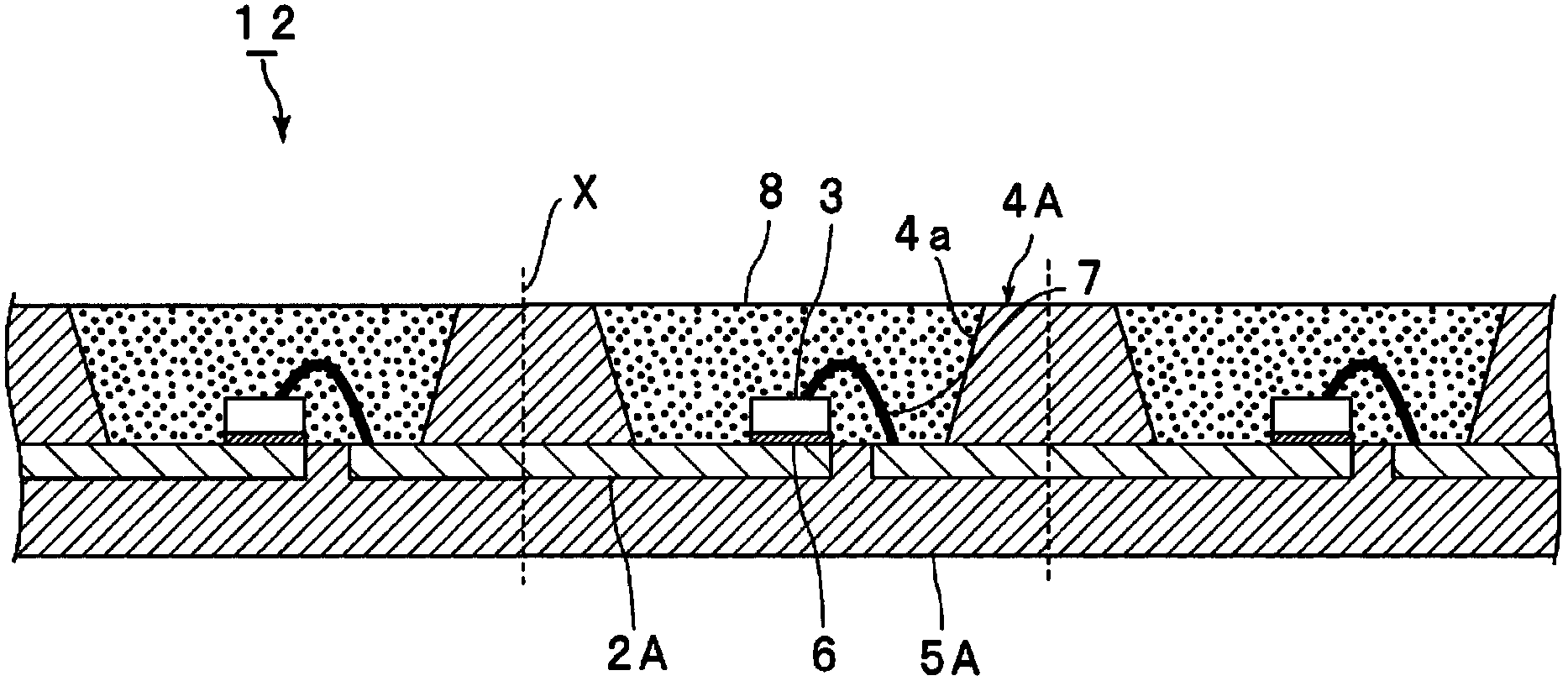

[0164] After forming a circuit by etching on a copper material (TAMAC194), silver plating was performed to obtain a lead frame with a thickness of 0.2 mm. Using a plunger injection method device (“YPS-MP” manufactured by TOWA Corporation), the above-mentioned curable composition was produced on the lead frame by plunger injection (molding temperature 170° C., molding time 3 minutes) by the MAP molding method. The o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com