Thermal insulation material and method for producing same

A heat-insulating material and manufacturing method technology, applied to chemical instruments and methods, ceramic products, electronic equipment, etc., can solve problems such as difficulty in maintaining the heat-insulating structure, inability to maintain the shape, collapse of the heat-insulating material, etc. Crack, strength, and heat resistance improvement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~15、17

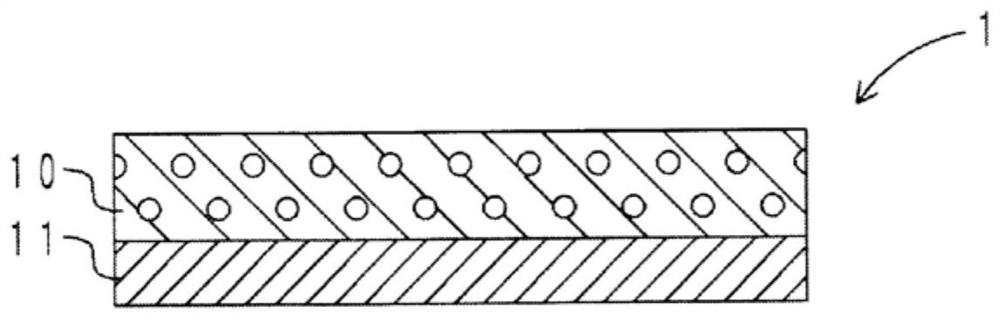

[0068] Add carboxymethyl cellulose (CMC; manufactured by Sigma-Aldrich) as a thickener to colloidal silica (aqueous dispersion of silica particles; "LUDOX (registered trademark) LS" manufactured by Sigma-Aldrich) Carboxymethylcellulose sodium salt, molecular weight is 380,000) and stirring. Next, the pulverized silica airgel was added and stirred, and glass fibers were further added and stirred to prepare a coating material for a heat insulating layer. The pulverized product of silica aerogel is obtained by pulverizing silica aerogel ("P200" manufactured by Cabot Corporation) with hydrophobic parts on the surface and inside using a household mixer to make it spherical , with an average particle size of 100 μm. As for the glass fiber, five types (A to E) having different aspect ratios (length / diameter) were selected from "chopped strands" manufactured by NEC Glass Co., Ltd. and used.

Embodiment 16

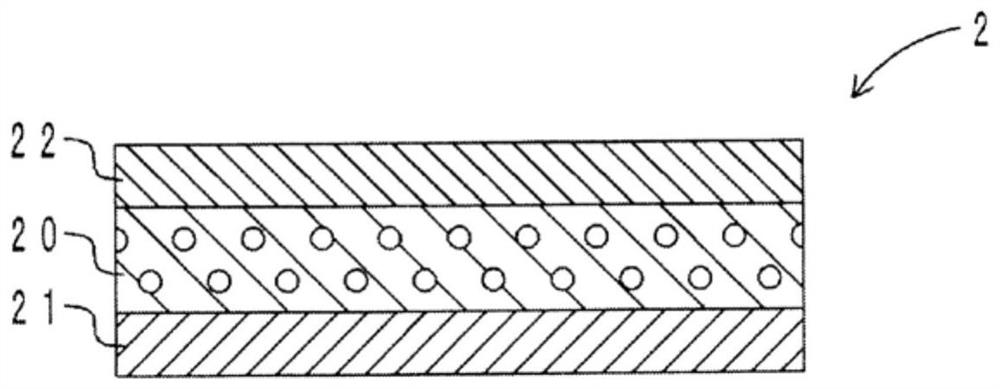

[0070] In place of the pulverized silica airgel, a non-pulverized silica airgel ("P200" manufactured by Cabot Corporation) was used, and the coating material for the heat insulating layer was prepared in the same manner as in Example 2. . The paints for heat insulating layers of Examples 1 to 17 are included in the concept of the paint for heat insulating layers of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com