Scribing wheel

A technology for scoring wheels and knife tips, which is applied to glass manufacturing equipment, stone processing tools, glass cutting devices, etc., to achieve the effects of prolonging life, suppressing wear and tear, and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

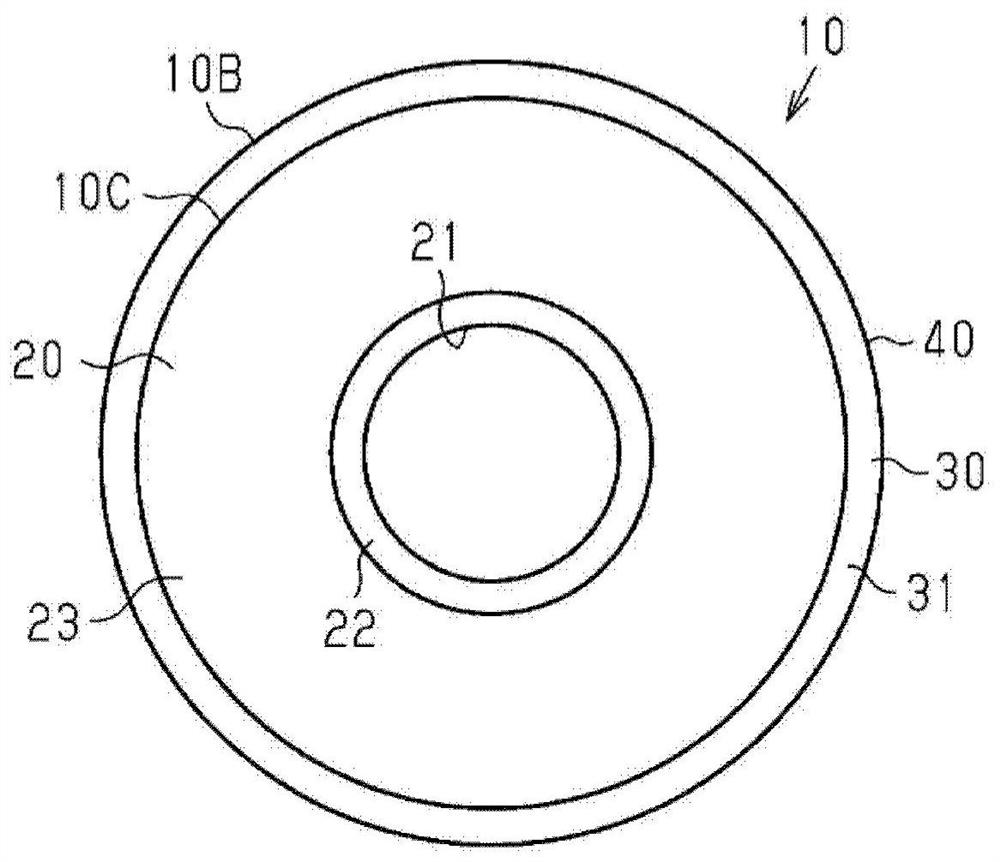

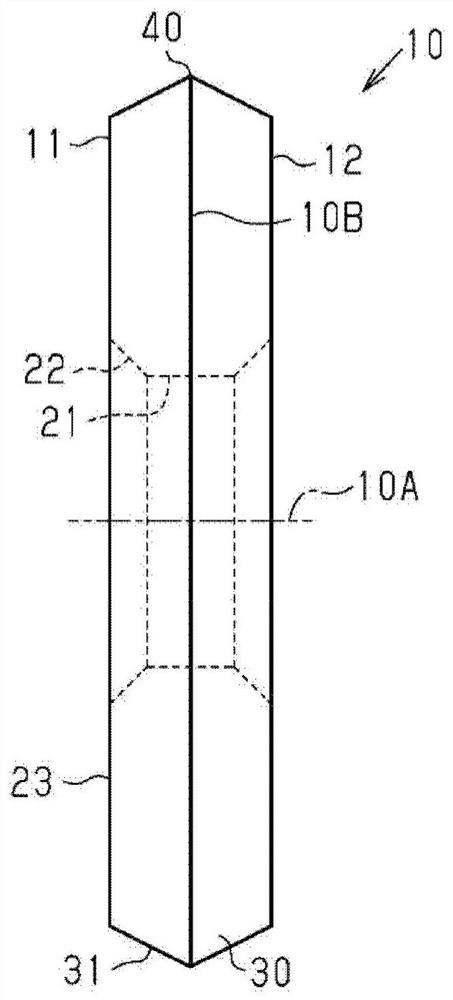

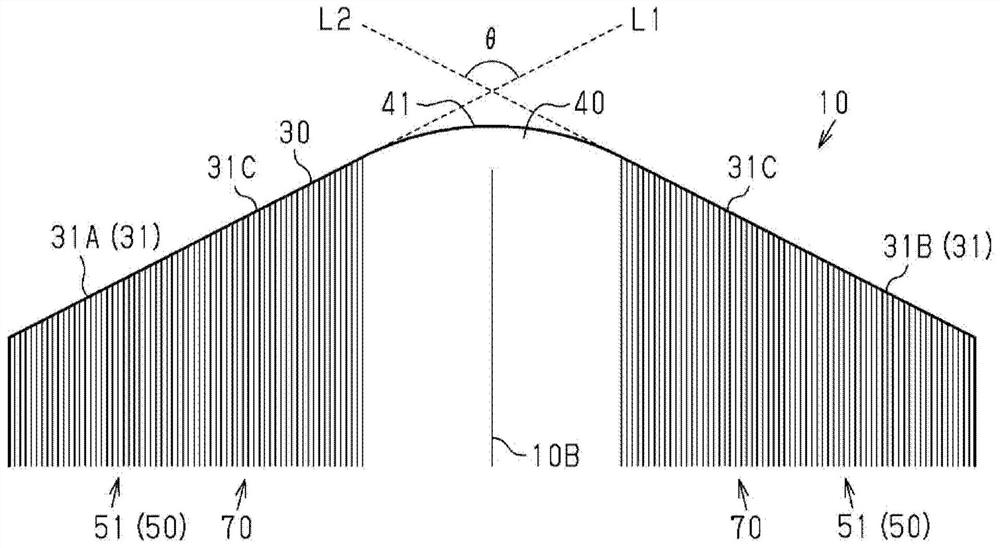

[0088] figure 1 The illustrated scoring wheel 10 is used for scoring machining of workpieces. The workpiece is, for example, a substrate. The substrate is, for example, a brittle material substrate. The brittle material substrate is, for example, a glass substrate or a ceramic substrate. The scoring wheel 10 includes a main body 20 and a blade edge portion 30 . In the scoring wheel 10, at least the cutting edge portion 30 is formed of a high-hardness material. The high hardness material is, for example, diamond sintered compact, single crystal diamond or polycrystalline diamond. The basic structure of the scoring wheel 10 is classified into a first structure and a second structure, for example. In the first configuration, the scoring wheel 10 is entirely formed of a high hardness material. In the second configuration, the scoring wheel 10 includes a non-high hardness portion formed of a non-high hardness material, and a high hardness portion formed of a high hardness mat...

no. 2 approach

[0137] Figure 9 A scoring wheel 100 of a second embodiment is shown. The structure of the scoring wheel 100 of the second embodiment corresponds to a partially modified structure of the scoring wheel 10 of the first embodiment. The rounding process is not performed on the front end portion 110 of the scoring wheel 100 of the second embodiment. In other points, the scoring wheel 10 of the first embodiment and the scoring wheel 100 of the second embodiment have the same structure. In each of the scoring wheels 10 , 100 , the same reference numerals are assigned to common structures.

[0138] The tip portion 110 of the scoring wheel 100 is sharper than the tip portion 40 of the first embodiment. The front end surface 111 of the front end portion 110 is smooth. The scoring wheel 100 is equipped with the contact suppression structure 50 similarly to the scoring wheel 10 of 1st Embodiment. Each cutting edge surface 31A, 31B is divided into main surface 31C and front end surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com