Ice making unit for flow down type ice maker

An ice making machine and ice making plate technology, which is applied in the directions of ice making, ice making, lighting and heating equipment, etc., can solve the problems such as the lengthening of the upper and lower dimensions of the ice making plate, the inability to use ice cubes, the need for time, etc., to achieve ice making. Ability-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

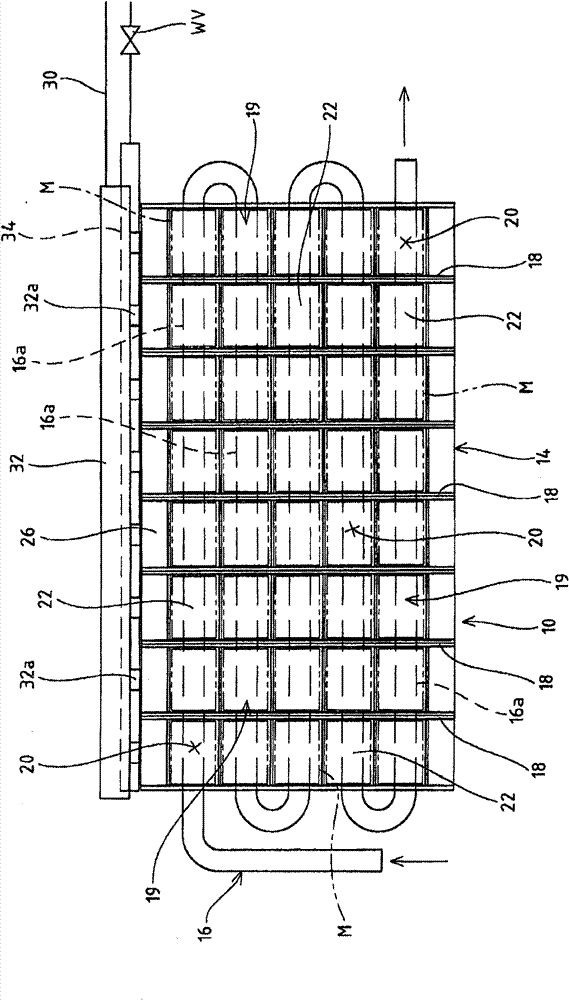

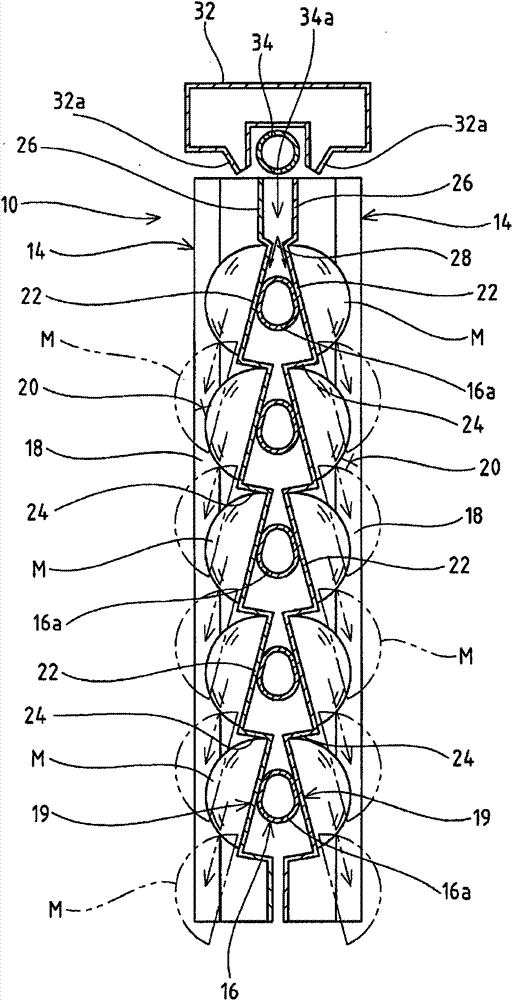

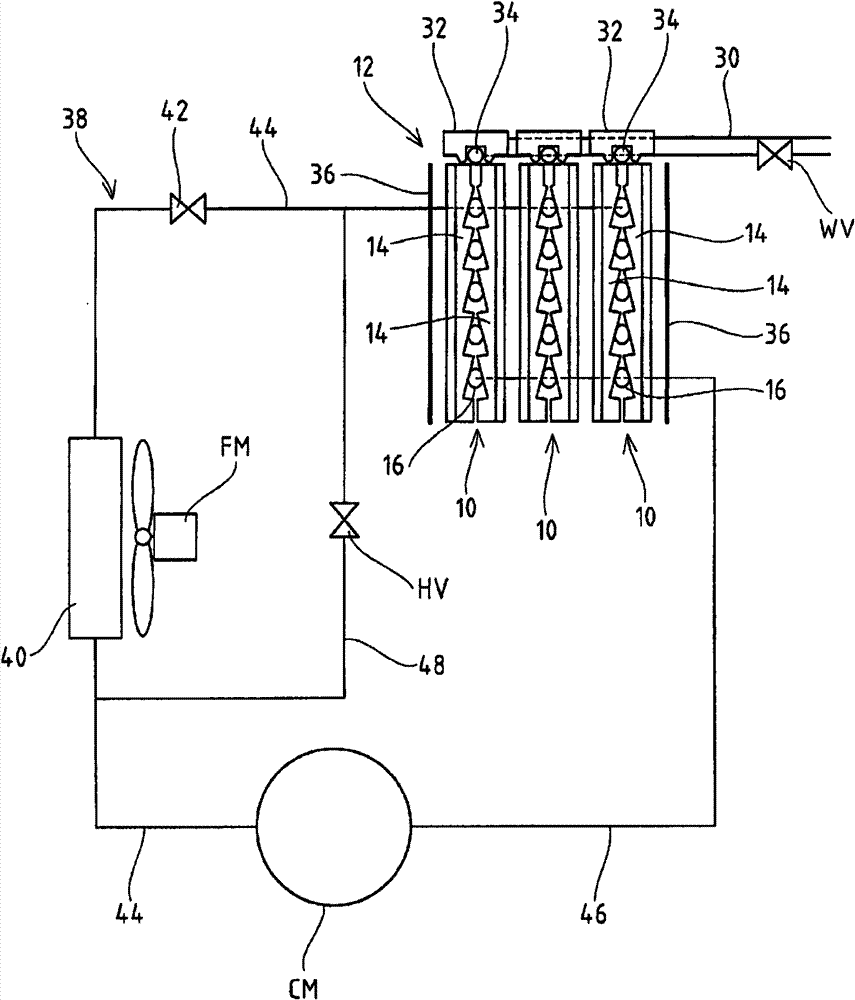

[0024] figure 1 It is a longitudinal sectional side view showing the ice making part 10 of the embodiment of the present invention, figure 2 It is a schematic configuration diagram of a downflow ice machine having an ice making unit 12 configured by arranging a plurality of ice making units 10 in parallel. in addition, image 3 is the overall representation figure 1 The schematic perspective view of the ice making part 10 shown. In the downflow type ice machine, the ice making unit 12 is arranged above the ice storage chamber (none of which is shown) divided into the inside of the heat insulation box, and the ice cubes M made by the ice making unit 12 are discharged and stored below. in the ice storage compartment. Such as figure 1 and image 3 As shown, each ice making unit 10 constituting the ice making unit 12 includes: a pair of ice making plates 14, 14 arranged longitudinally; 16. Such as Figure 4 As shown, the laterally extending portion 16a of the evaporating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com