Continuous forming system for laminated veneer lumber

A technology of laminated veneer lumber and veneer, which is applied in the jointing of wooden veneers, wood processing equipment, manufacturing tools, etc. Low efficiency and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

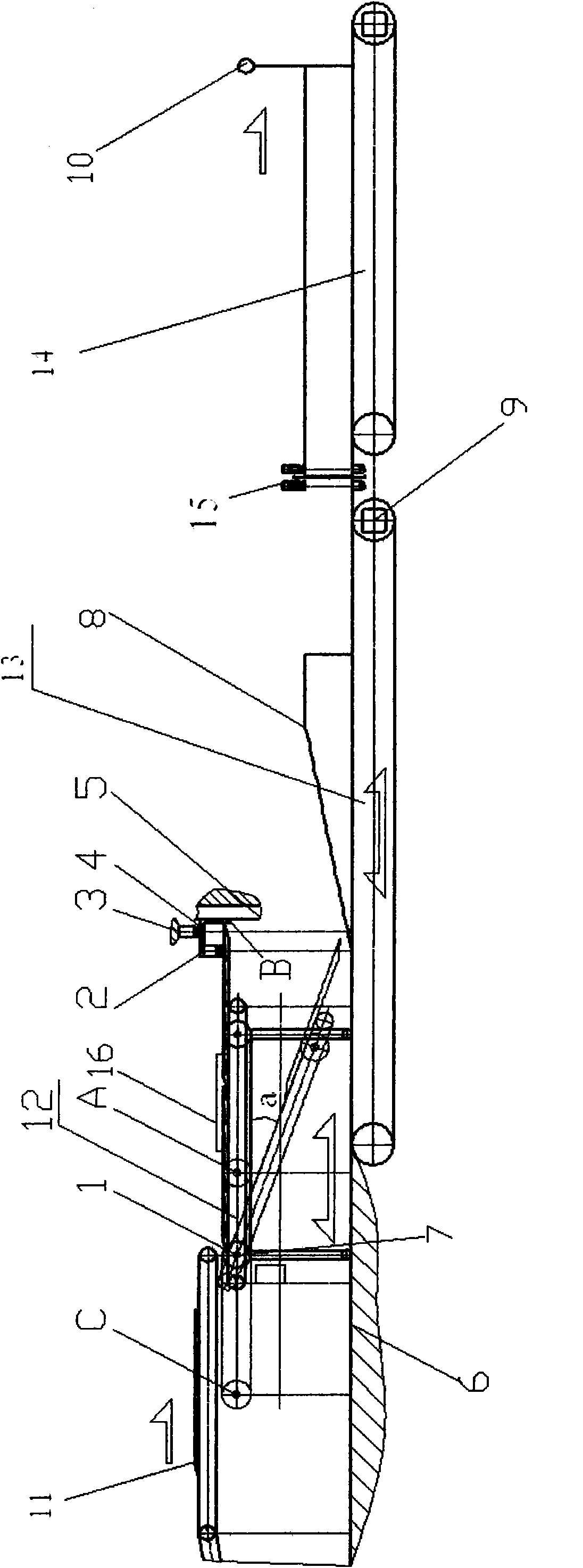

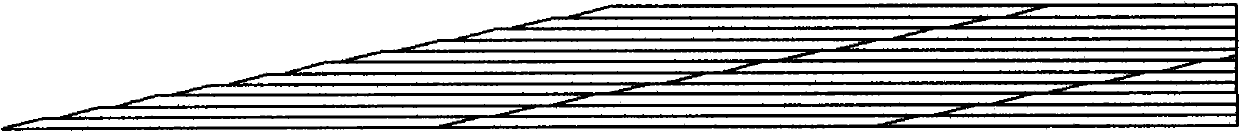

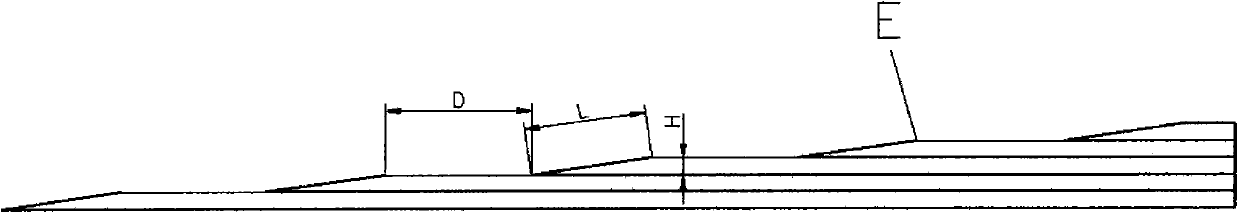

[0020] Specific implementation mode one: refer to Figure 1 to Figure 4 , The continuous pavement of the laminated veneer lumber in this embodiment is completed according to the following steps. One, the veneer with a thickness of 3mm, which has been graded and matched by moisture content, density and surface quality, is subjected to oblique grinding at both ends by an oblique mill (21), and the slope length of the oblique grinding is 30mm; The veneer passes through the glue brushing machine (22) to brush glue on the oblique grinding parts at both ends, then passes through the glue spreader (23) to apply glue on the upper surface, and is transported to the front part of the mobile paving head (12) by the belt conveyor (11) and waits; 3. The veneer enters the belt conveyor (1) of the mobile paving head (12) at station A and is transported forward to the baffle (4), and the belt conveyor (1) passes through the rotation at station O The reduction motor (7) rotates 15° clockwise,...

specific Embodiment approach 2

[0021] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the veneer thickness is 2mm, and the slope length of the oblique mill is 20mm. After completing the paving of a veneer, the pavement belt conveyor (13) is backward The stepping distance is 100mm. Other specific implementations are the same as the first specific implementation.

specific Embodiment approach 3

[0022] Specific embodiment three: the difference between this embodiment and specific embodiment one is that the veneer enters the belt conveyor (1) of the mobile paving head (12) at station A and is transported forward to the baffle plate (4 ), the belt conveyer (1) rotates 60° clockwise through the rotating deceleration motor (7) at the station O, and at the same time the compression cylinder (3) is pressed down so that the compression cylinder (2) and the baffle (4) move along the guide rail (5) Move down to the veneer so that the veneer falls into the ladder formwork (8). Other specific implementations are the same as the first specific implementation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com