Method of analyzing product structure and properties by the utilization of samples prepared with thermo-stimulated test

A thermal simulation and performance technology, applied in the field of iron and steel materials, can solve the problems of difficult control of process parameters, inability to collect key data, and inability to accurately realize, and achieve the effect of saving R&D costs and shortening the R&D cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A method for analyzing the structure and performance of a sample after thermal simulation according to the present invention, the main chemical components are: C: 0.13%, Si: 0.25%, Mn: 1.45%, P: 0.018%, S: 0.002 %, Nb: 0.04%, V: 0.050% of the microalloyed steel, the research on the properties of different final rolling temperatures is carried out according to the following steps:

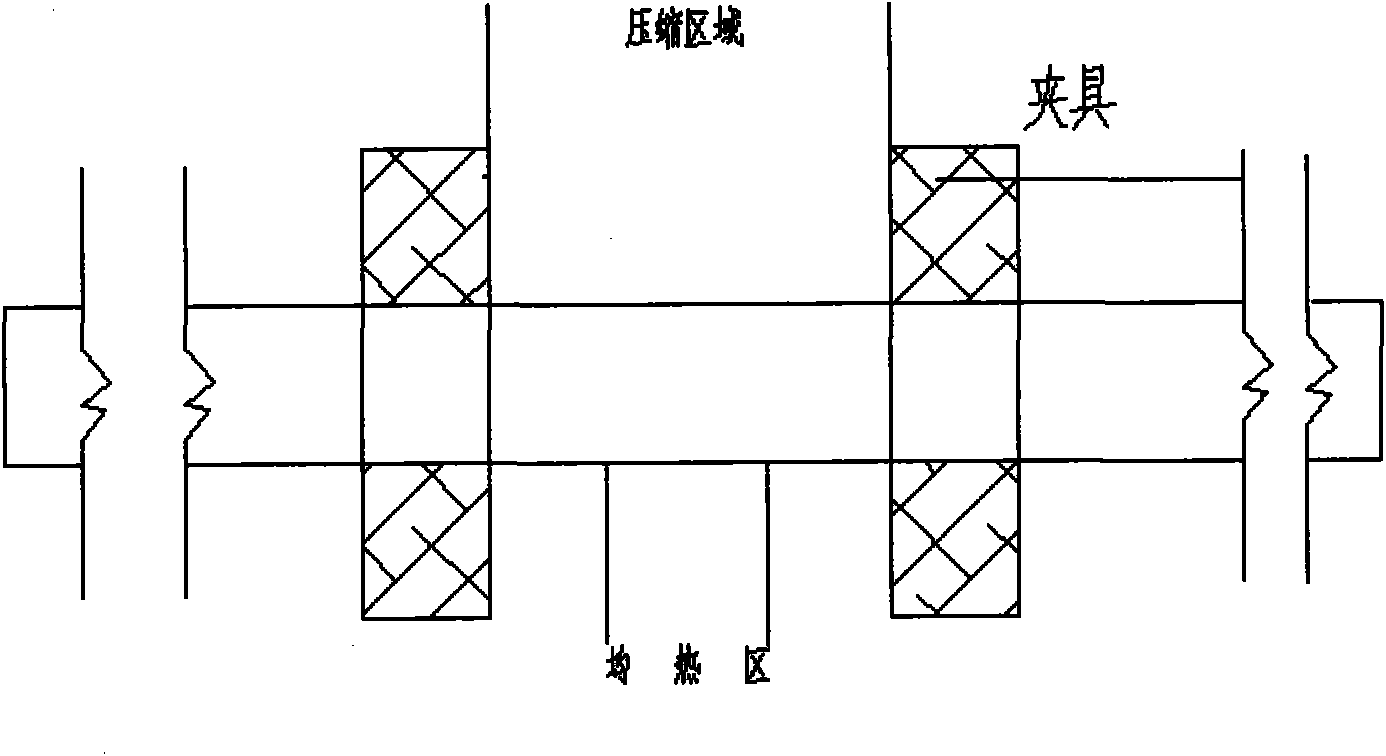

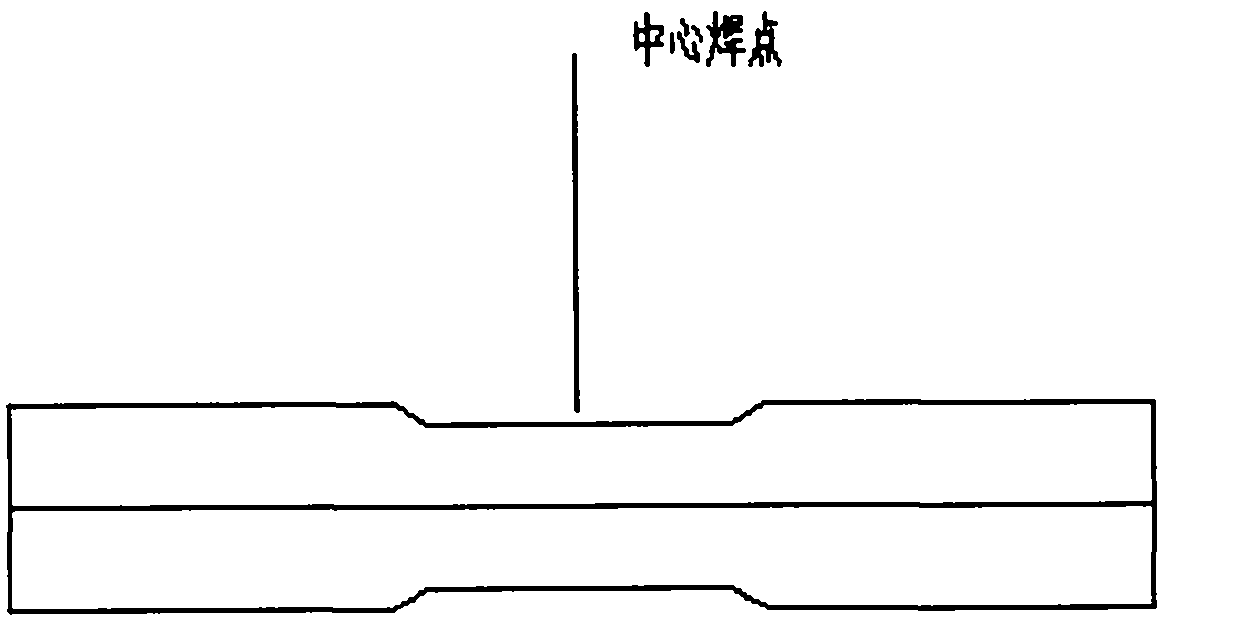

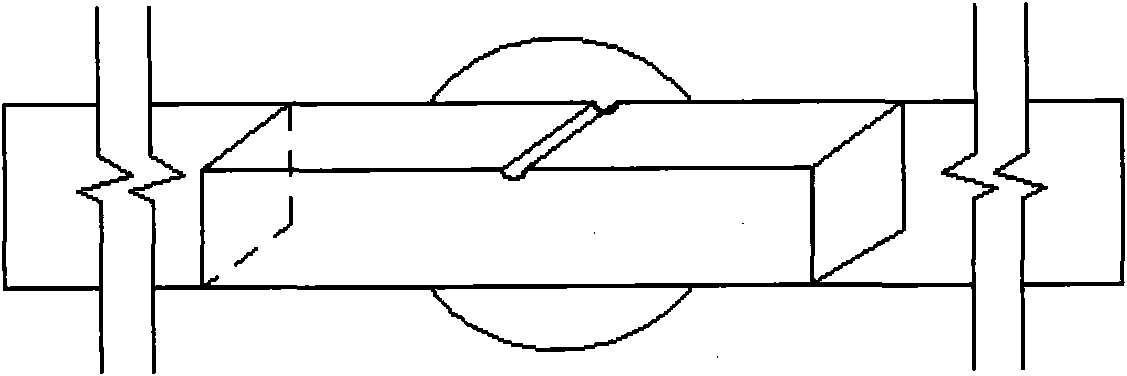

[0019] 1) Process the experimental steel into such as figure 1 In the shape shown, the sample size is Φ10mm×85mm, and it is installed in the sample cavity with the special fixture of the thermal simulation testing machine;

[0020] 2) Raise the sample to 1200°C at a heating rate of 5°C / s on the thermal simulation testing machine, so that various microalloying elements are solid-dissolved into the austenite, and carry out two-stage controlled rolling after holding for 5 minutes;

[0021] 3) First drop to 1050°C at a rate of 5°C / s, and at a strain rate of 1s -1 , Compress the sample with 45% ...

Embodiment 2

[0029] Another method of the present invention that directly uses the sample after thermal simulation to analyze the structure and performance, the main chemical composition is: the main chemical composition is: C: 0.08%, Si: 0.25%, Mn: 1.48%, P : 0.015%, S: 0.003%, Nb: 0.056%, Ti: 0.01%, Ni: 0.22%, Mo: 0.24%, B: 0.001% of low-alloy high-strength steel, the research on the performance of different relaxation time after rolling , proceed as follows:

[0030] 1) Process the experimental steel into such as figure 1 In the shape shown, the sample size is Φ10mm×85mm, and it is installed in the sample cavity with the special fixture of the thermal simulation testing machine;

[0031] 2) Raise the sample to 1250°C at a heating rate of 5°C / s on the thermal simulation testing machine, so that various microalloying elements are solid-dissolved into the austenite, and carry out two-stage controlled rolling after holding for 8 minutes;

[0032] 3) First drop to 1050°C at a rate of 5°C / s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com