Method of detecting fruit surface defect based on low pass filter

A defect detection and low-pass filtering technology, which is applied in the direction of optical test defect/defect, instrument, character and pattern recognition, etc., can solve the problems of increasing image processing workload and reducing the processing speed of machine vision system, etc., to achieve strong adaptability, The effect of overcoming complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with drawings and embodiments.

[0040] 1) Image acquisition: take the blue cardboard as the background, put the fruit on the sample table, and take a color image of the fruit;

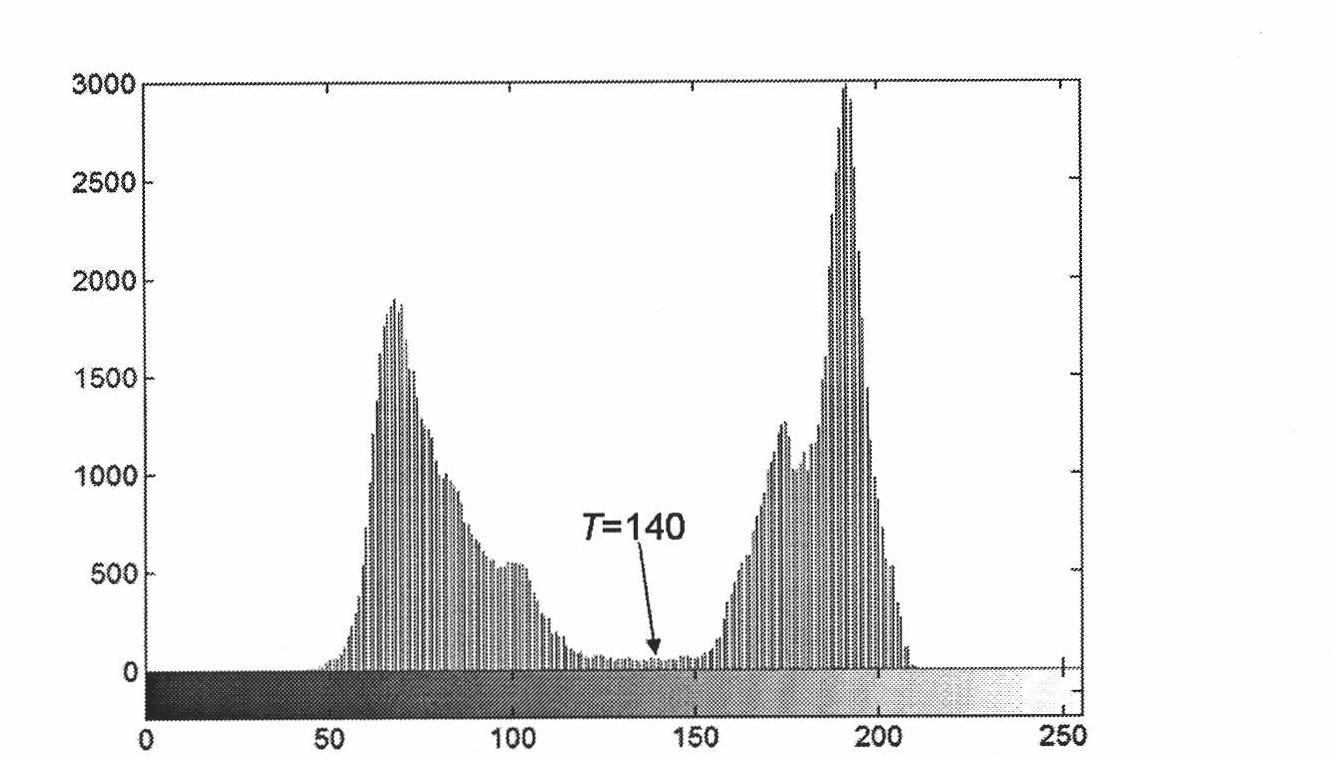

[0041] 2) Background removal: extract the R and B component images of the color image, such as figure 1 and figure 2 shown. Then according to the B component image histogram image 3 (The peak on the left of the histogram represents the fruit, and the peak on the right represents the background) Select the threshold T=140 to binarize the B component image to form the following Figure 4 In the binary image B' shown, the area with fruit is set to 1, and the rest of the area is set to 0. Using the formula (1), the R component image f(x, y) after removing the background is obtained by dot multiplication between the R component image and the B′ image, as shown in Figure 5 shown;

[0042] f(x,y)=R.*B' (1)

[0043] 3) Cente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com