Vertical transmission device for vertical roller of rolling mill

A technology of transmission device and vertical roll, which is applied to the driving device of metal rolling mill, metal rolling stand, metal rolling mill stand, etc., which can solve the problem of quality reduction of rolled steel pipe products and insufficient force of horizontal roll and vertical roll Balanced, uneven metal flow and other problems, to achieve the effect of good rolling forming quality, convenient and quick roll change, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

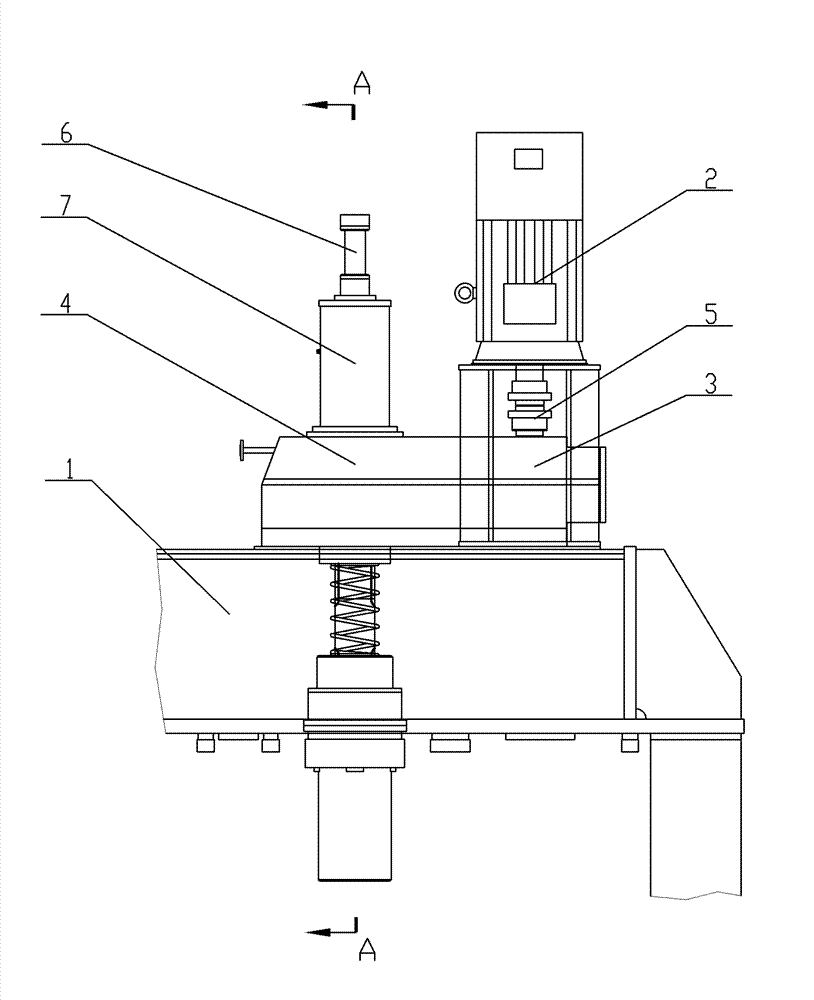

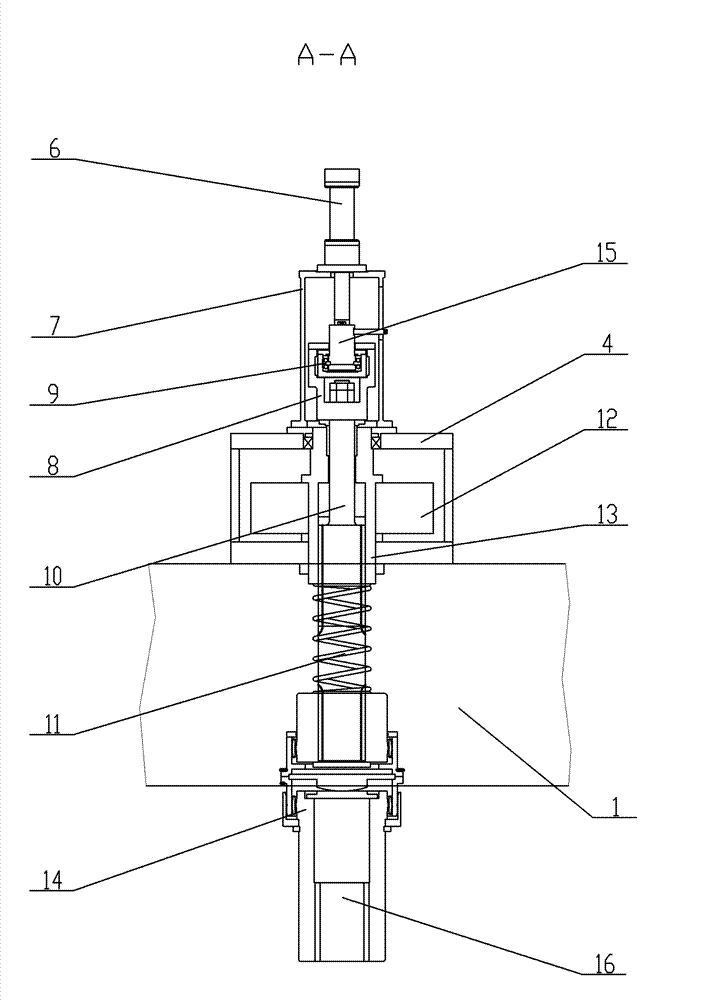

[0014] figure 1 , 2 Shown is the specific embodiment of the present invention, and it is the vertical transmission device of rolling mill vertical roller installed on the rolling mill in steel pipe four-roll thermal sizing unit; Its structure comprises the vertical roller shaft 16 of both sides, is characterized in that: with The vertical transmission device of the vertical roller is installed on the crossbeam 1 corresponding to the vertical roller shaft 16 position of each side, and the vertical transmission device of the vertical roller is composed of a motor base 3, a motor 2, a safety coupling 5, a reduction box 4 and The hydraulic cylinder lifts the roll changing mechanism of the flower roll, the spring 11 and the gear coupling 14. The reduction box 4 is a reduction box 4 of 4-stage gears. The output shaft in the reduction box adopts a spline shaft 10, so The upper shaft end and the lower shaft end of the spline shaft 10 described above are all exposed outside the reduct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com