Saddle-shaped pipe end cutting device

A pipe end cutting device, saddle type technology, applied in welding equipment, gas flame welding equipment, metal processing equipment, etc., can solve problems such as affecting the stability and safety of equipment, unfavorable popularization and use, and high structural layout requirements. , to achieve the effect of expanding the cutting operation range, easy purchase of casters, and light overall movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

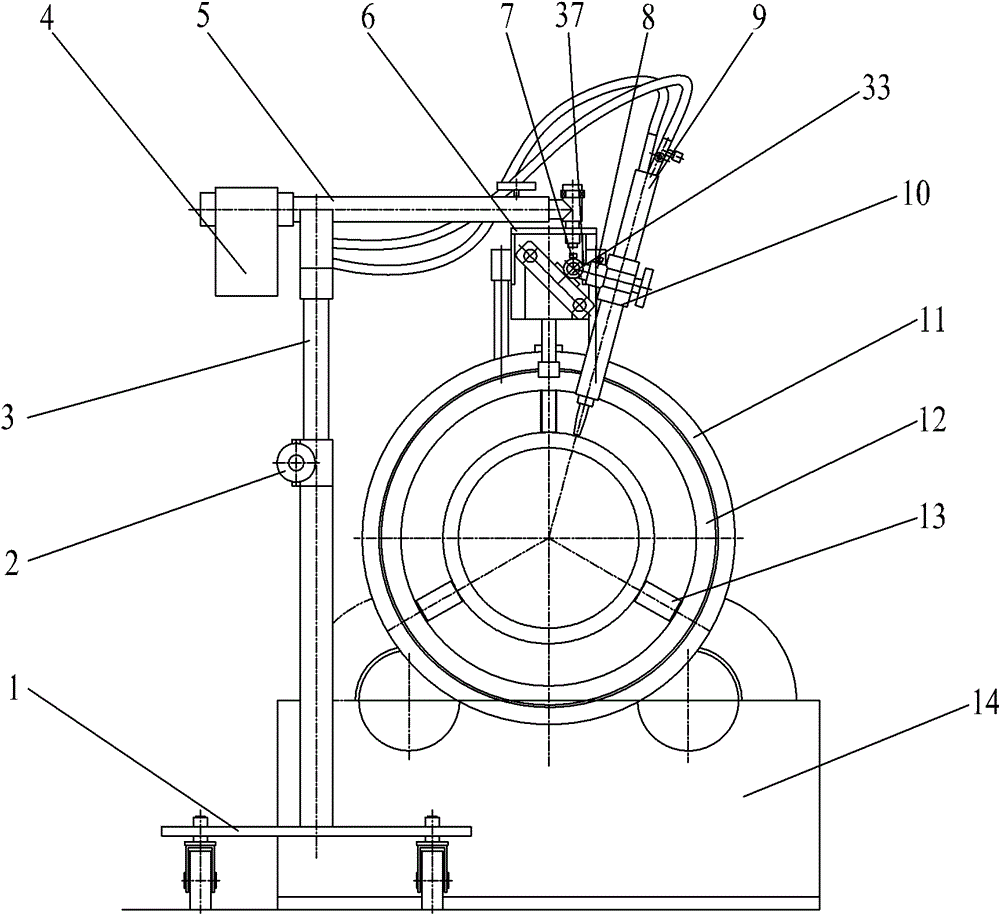

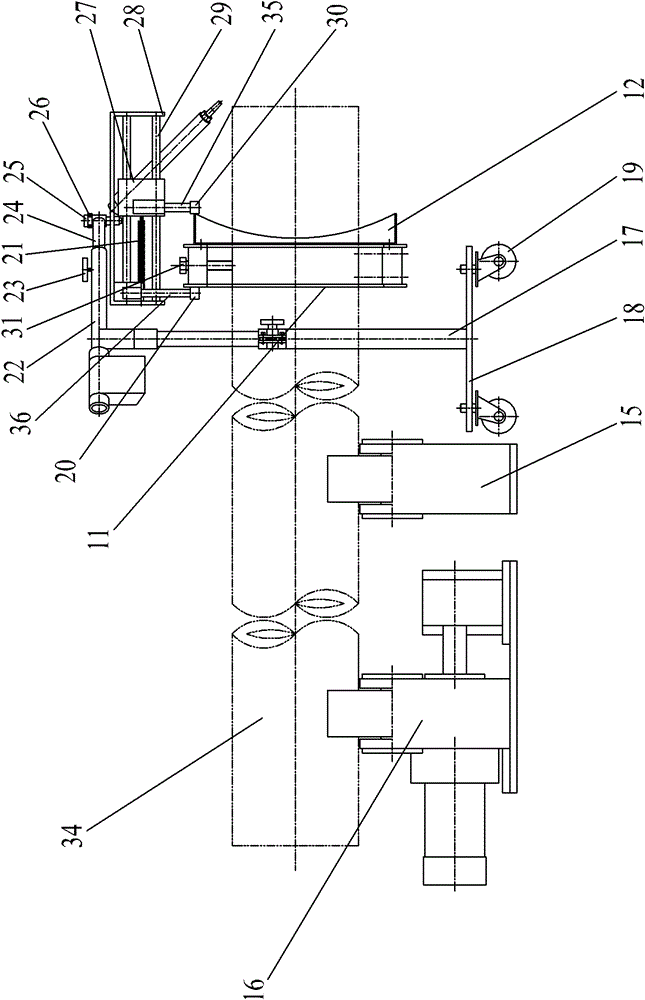

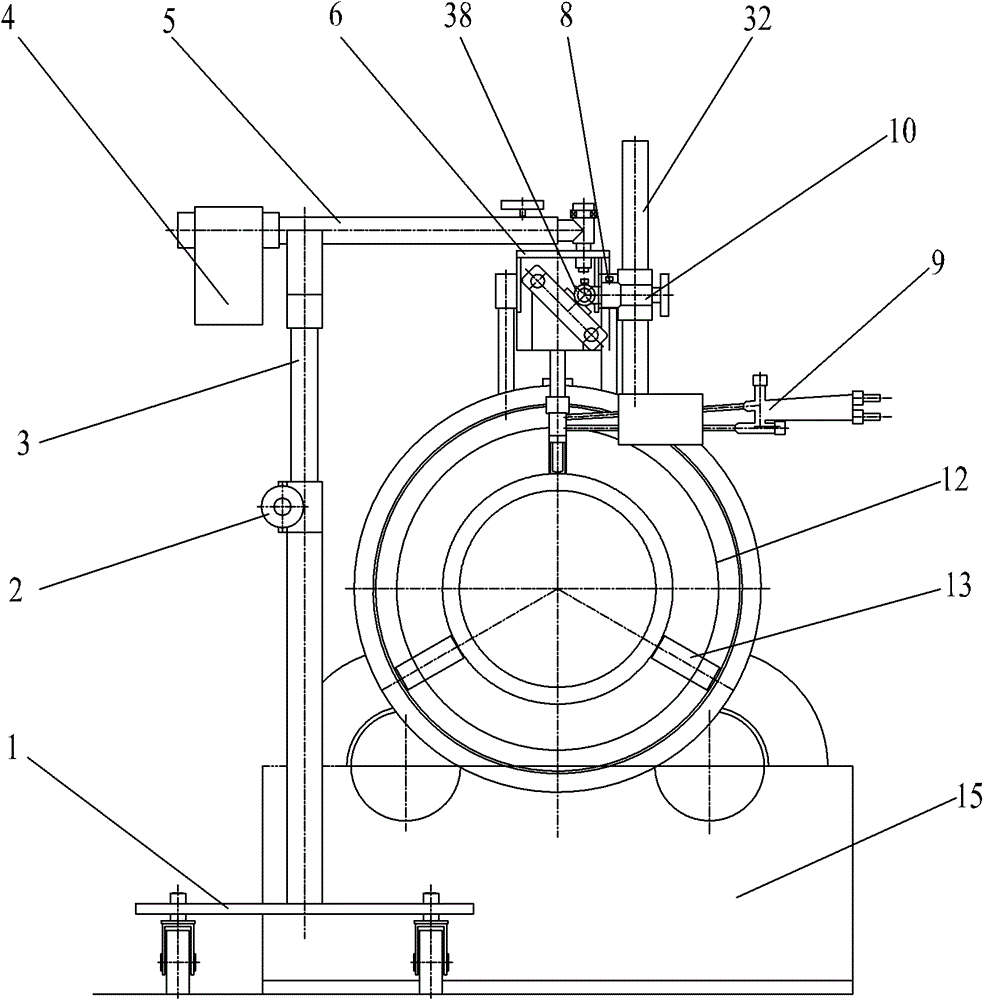

[0017] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0018] Such as Figure 1~Figure 3 As shown: the present invention includes a base 1, a lifting sleeve 2, a column 3, a balance weight 4, a cross arm 5, a hanger 6, a first positioning screw 7, a second positioning screw 8, a cutting torch 9, and a cutting torch adjustment sleeve 10 , Positioning sleeve 11, master mold 12, adjustment pad 13, overturning frame 14, driven wheel frame 15, driving wheel frame 16, column casing 17, bottom plate 18, casters 19, fixed pressure wheel 20, adjustment spring 21, inner tube Sleeve 22, inner tube set bolt 23, inner tube 24, pin shaft 25, bearing 26, slider 27, frame body 28, sliding shaft 29, movable pressure roller 30, compression bolt 31, auxiliary hanger 32, hinge Axle 33, workpiece 34, movable pinch roller connecting rod 35, fixed pinching roller connecting rod 36, connecting shaft 37 and hinged seat 38.

[0019] Such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com