Solar heat-absorbing pipe

A technology of solar heat absorption and bellows, which is applied in the field of solar thermal utilization, can solve the problems of complex process and scrapping of the whole tube

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

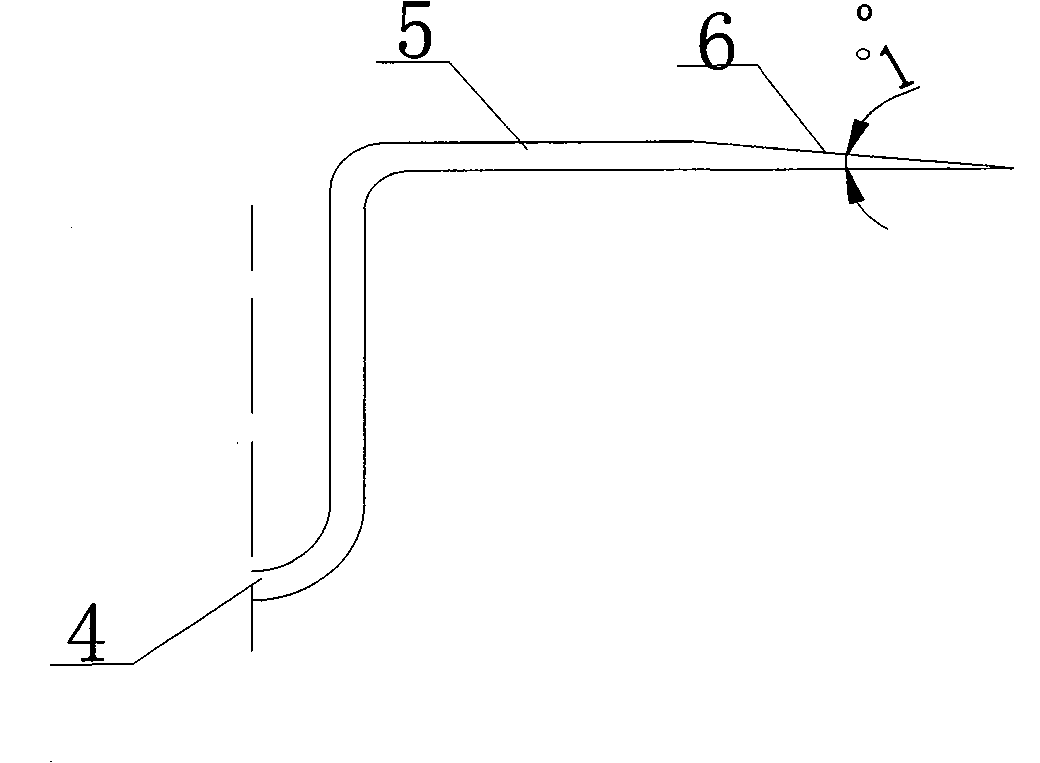

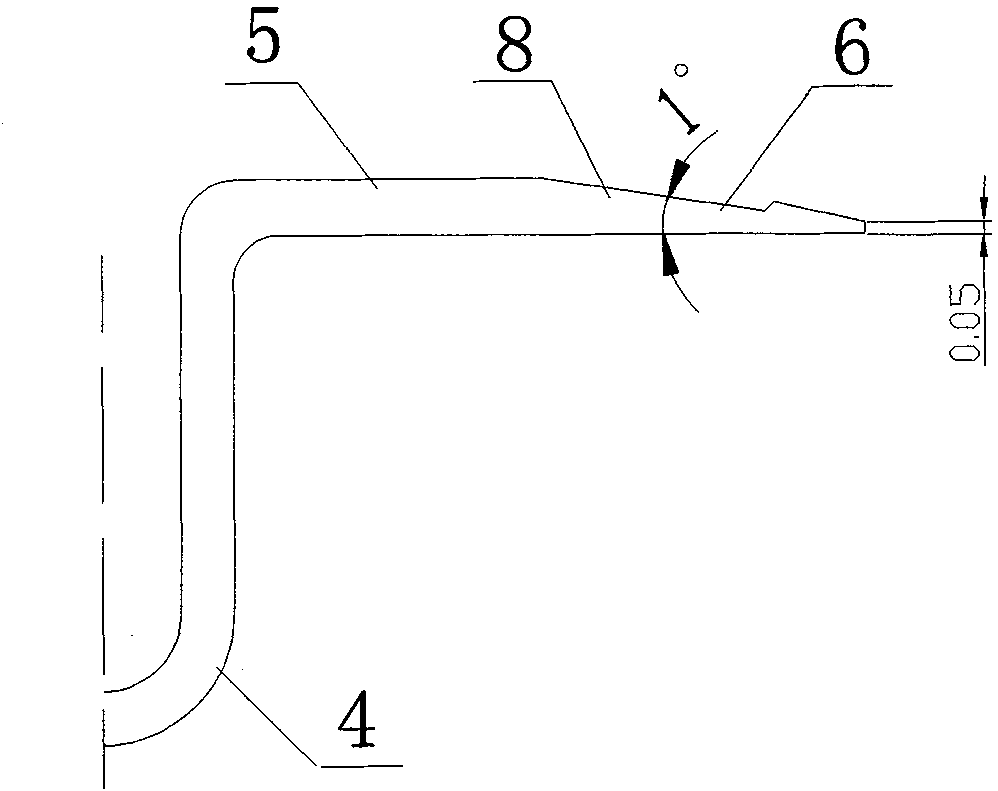

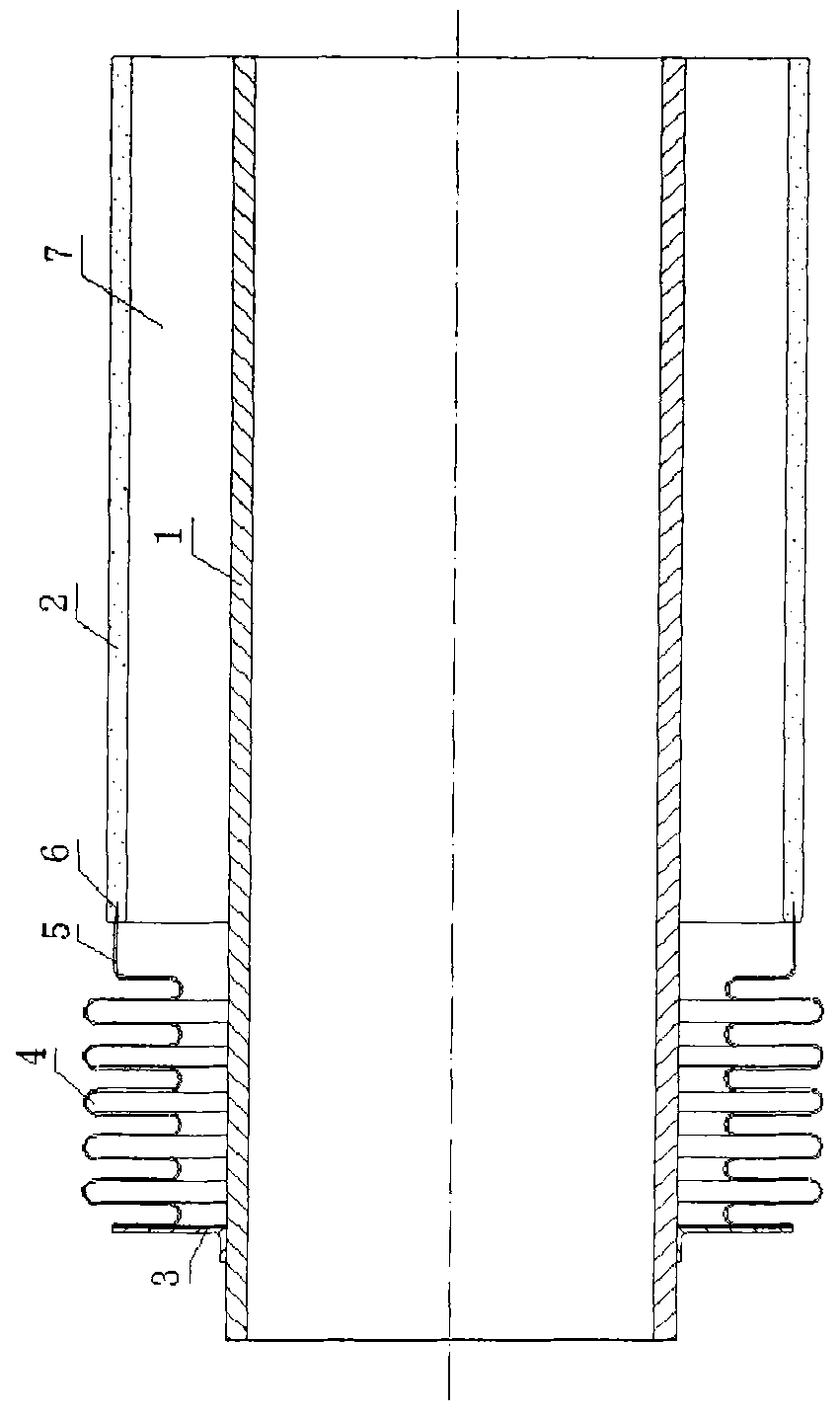

[0023] One end of the solar heat absorbing pipe of embodiment 1 of the present invention is as figure 1 shown. The solar heat absorbing tube includes a glass outer tube 2 and a metal inner tube 1 with a high temperature resistant selective absorbing coating. The metal inner tube 1 is made of 316L stainless steel alloy; the glass outer tube 2 is made of high borosilicate 3.3 glass. One end of the connector 3 is welded with the metal inner tube 1, and the other end of the connector 3 is welded with the bellows 4 with expansion compensation; the material of the bellows 4 is 304 stainless steel alloy, and the expansion coefficient is 17×10 -6 / K, with 5 corrugations, one end of the corrugated pipe 4 has a straight section 5, and the port of the straight section 5 is processed into the shape of a thin-walled knife edge 6, such as figure 2 As shown, the thickness of the thinnest edge of the thin-walled knife edge 6 is 0.03mm, the taper is 1°, and the length of the knife edge is 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coefficient of expansion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com