Detector for detecting friction moment of bearings

A detection device, friction torque technology, applied in the direction of measuring device, mechanical bearing test, torque measurement, etc., can solve the problems of guidance, difficult to use, unable to fully reflect the friction resistance of bearings, etc., to achieve improved recovery efficiency, true value, and improved The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

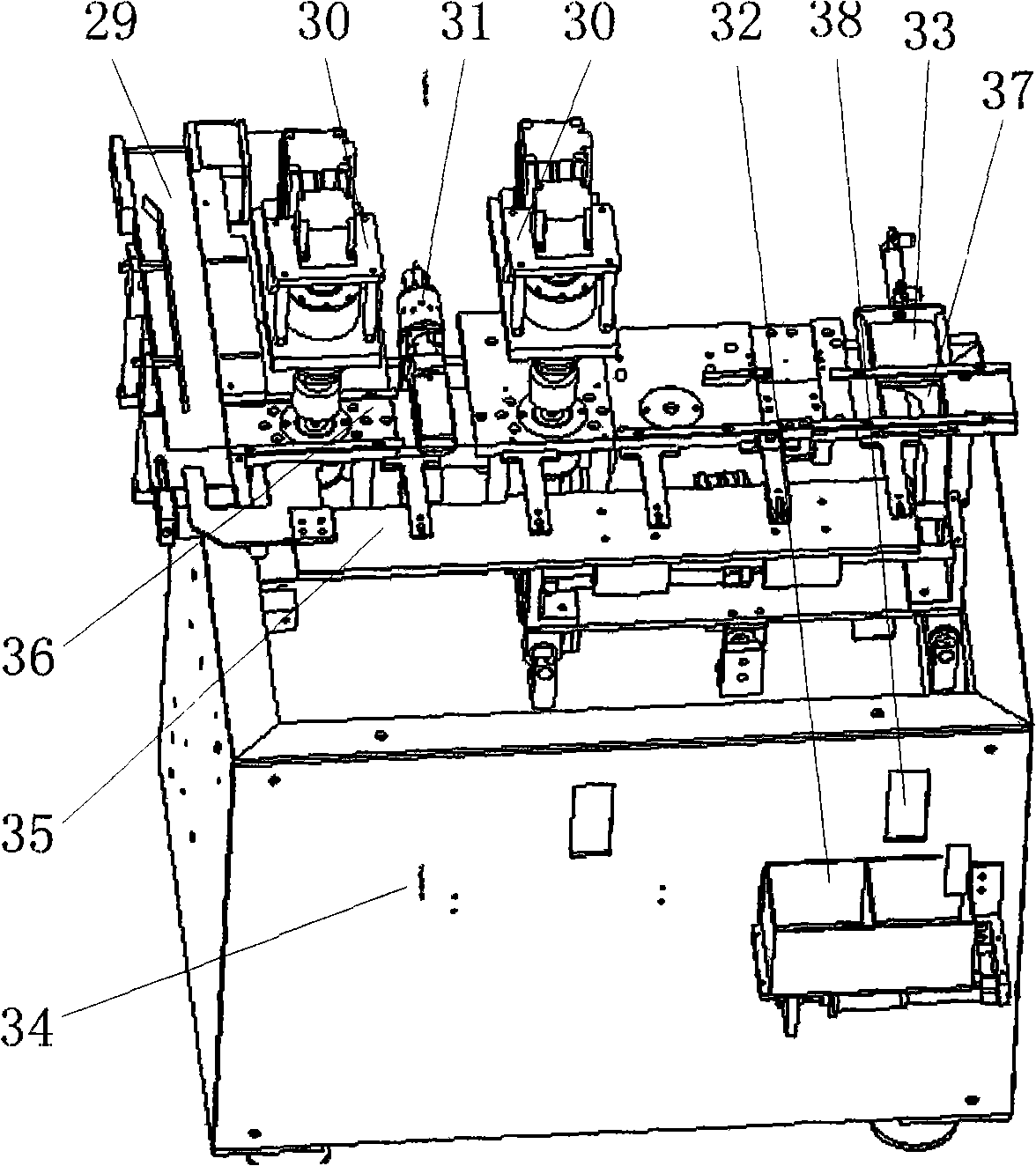

[0020] See figure 1 , the present invention comprises frame 34, and feeding mechanism 29, detection passage 36, material shifting mechanism 35 and recovery mechanism 32 are installed respectively on the frame 34, and the lower end of feeding mechanism 29 is that discharge opening 294 is flush with detection passage 36, for ease of description , assuming that the direction of the detection channel 36 is the horizontal direction, the installation direction of the belt 292 is the vertical direction.

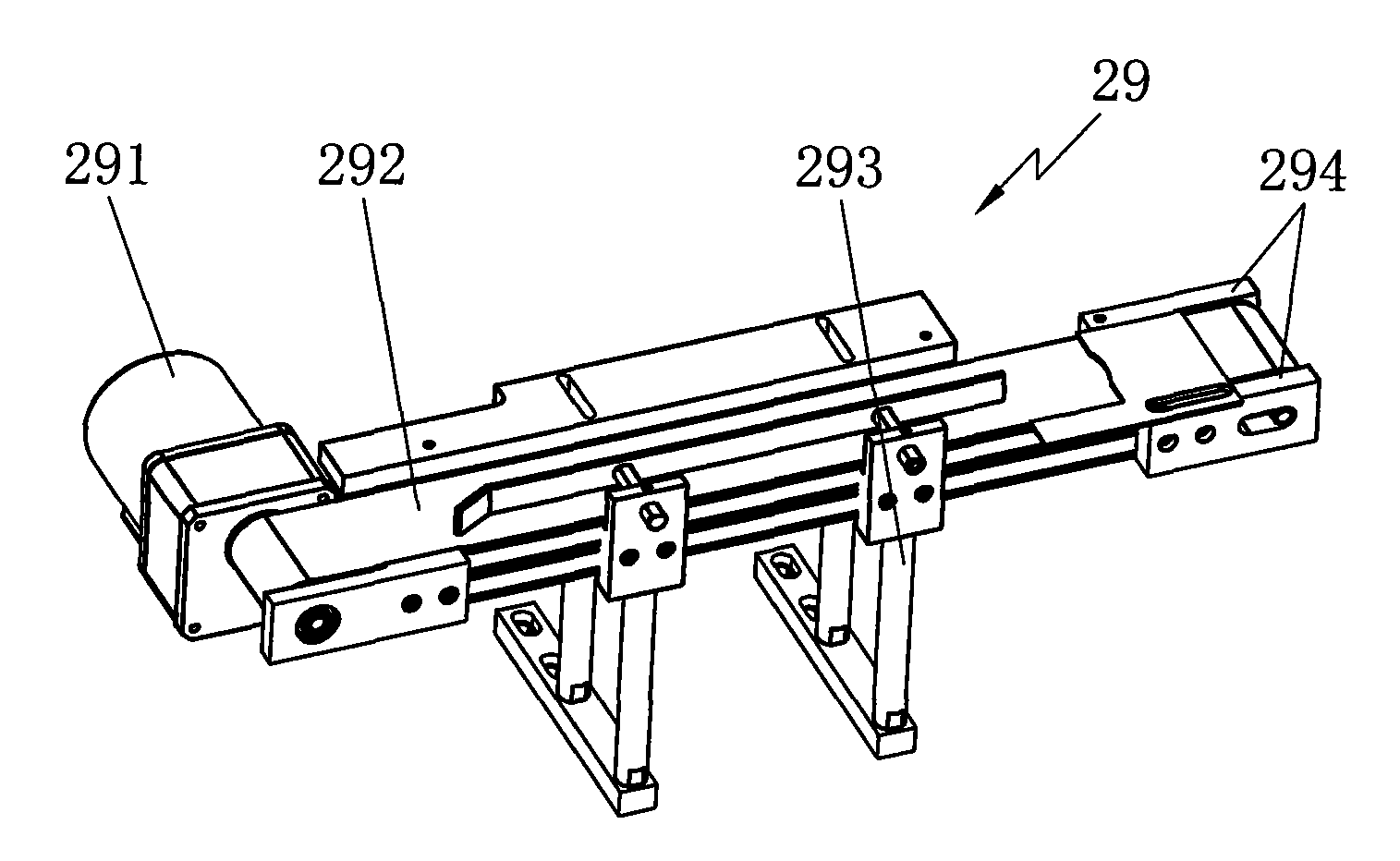

[0021] See image 3 , Feeding mechanism 29 comprises frame 293, and belt 292 is installed on the frame 293, and belt 292 is controlled by motor 291 and carries out circulation conveying motion, and the right end of belt 292 is provided with discharge port 294.

[0022] See Figure 4 , the dial mechanism 35 includes a frame 355, on which a guide rod 354 and a cylinder 356 are installed, the mounting plate 352 is connected with the guide rod 354 through a slider 353, the direction o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com