Magnetomotive and high reversal torque direct current motor

A DC motor, magnetic power technology, applied in the direction of magnetic circuit rotating parts, electrical components, electromechanical devices, etc., to achieve the effect of stable operation, long life, and inhibition of homeopathic motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

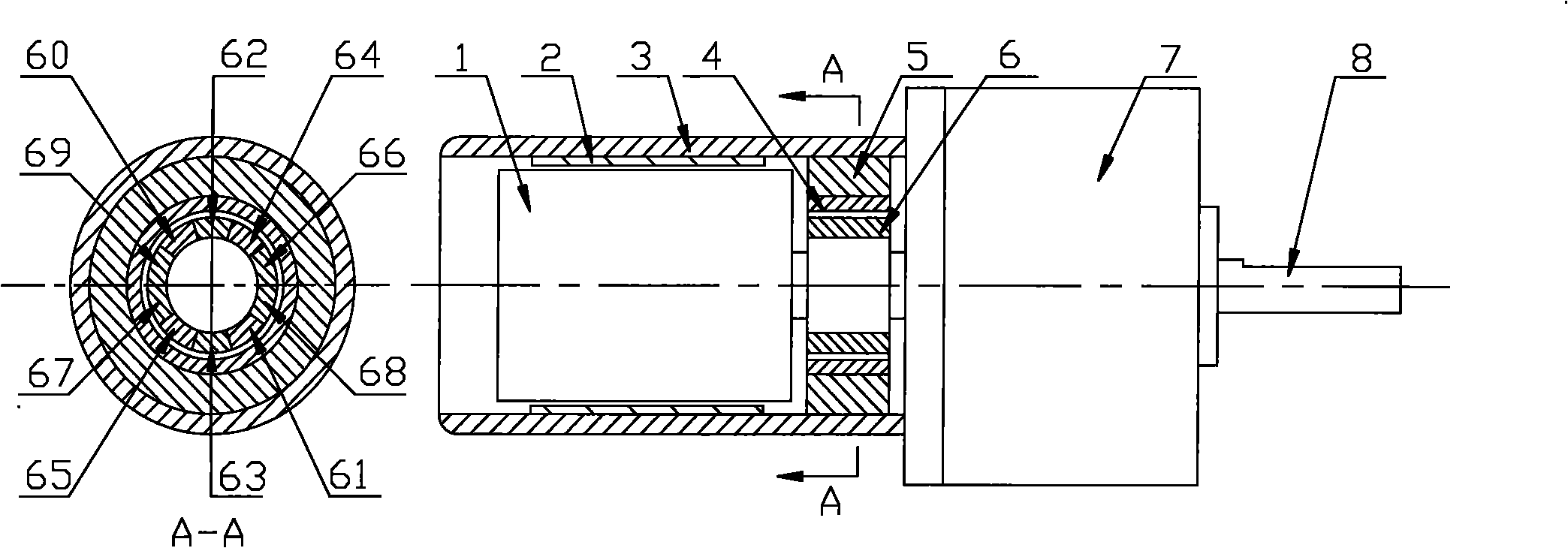

[0017] The following is attached with the manual figure 1 - attached Figure 4 The present invention is described further:

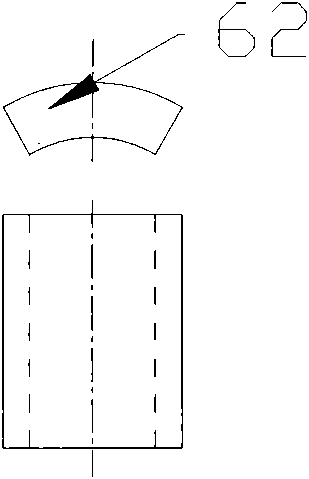

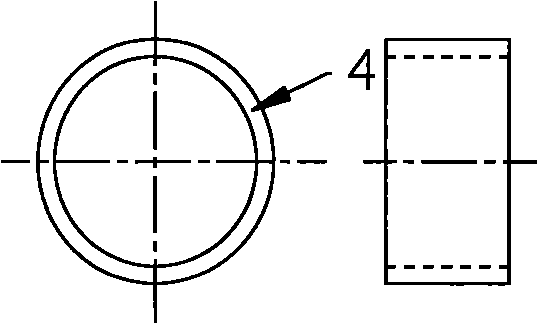

[0018] The design principle of the magnetic power high reverse torque DC motor of this embodiment is to change the traditional DC motor to add rotor and stator magnets at the connection between the motor axial rotor and the reducer, and to control the motor stop and position according to the principle of magnet subdivision Maintain precision. The cross-sectional view of the magnetic power high reverse torque DC motor is as follows: figure 1 As shown, it includes a motor rotor 1 , a motor stator 2 , a motor housing 3 , a stator magnet 4 , a cage 5 , a rotor magnet 6 , a reducer 7 and a motor output shaft 8 . The motor stator 2 is fixed on the motor housing 3, which is 2 pieces, and the circumferential direction of each piece is about 60 degrees. The motor rotor 1 rotates in the motor stator 2 to generate induced electromotive force and torsional torque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com