Manufacture method of tobacco strips and air groove

A manufacturing method and technology of air grooves, applied in the manufacture of tobacco rods, and the field of air grooves for manufacturing tobacco rods, can solve problems such as damaging flow conditions, frictional heating, and quality deviation of tobacco rods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

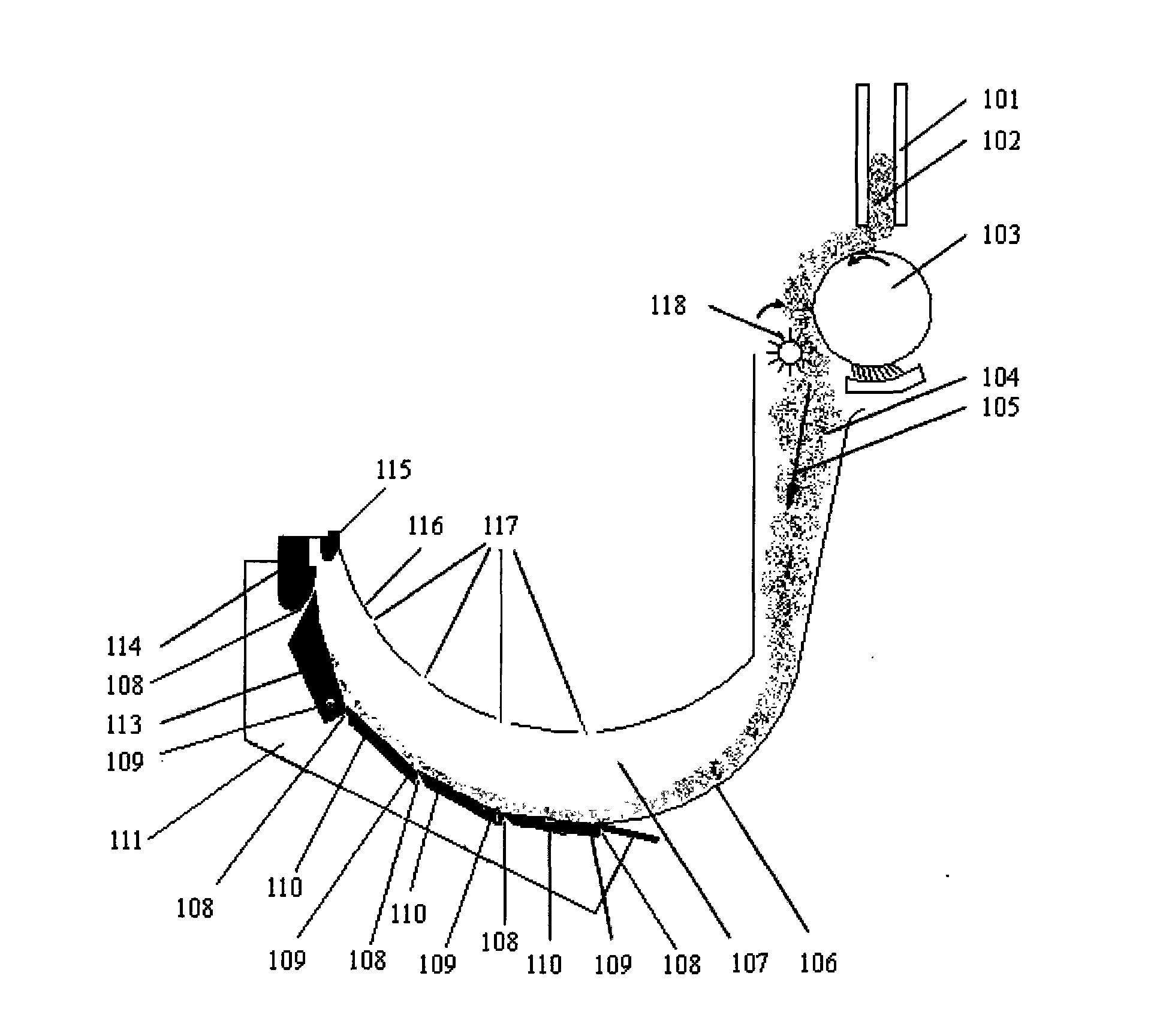

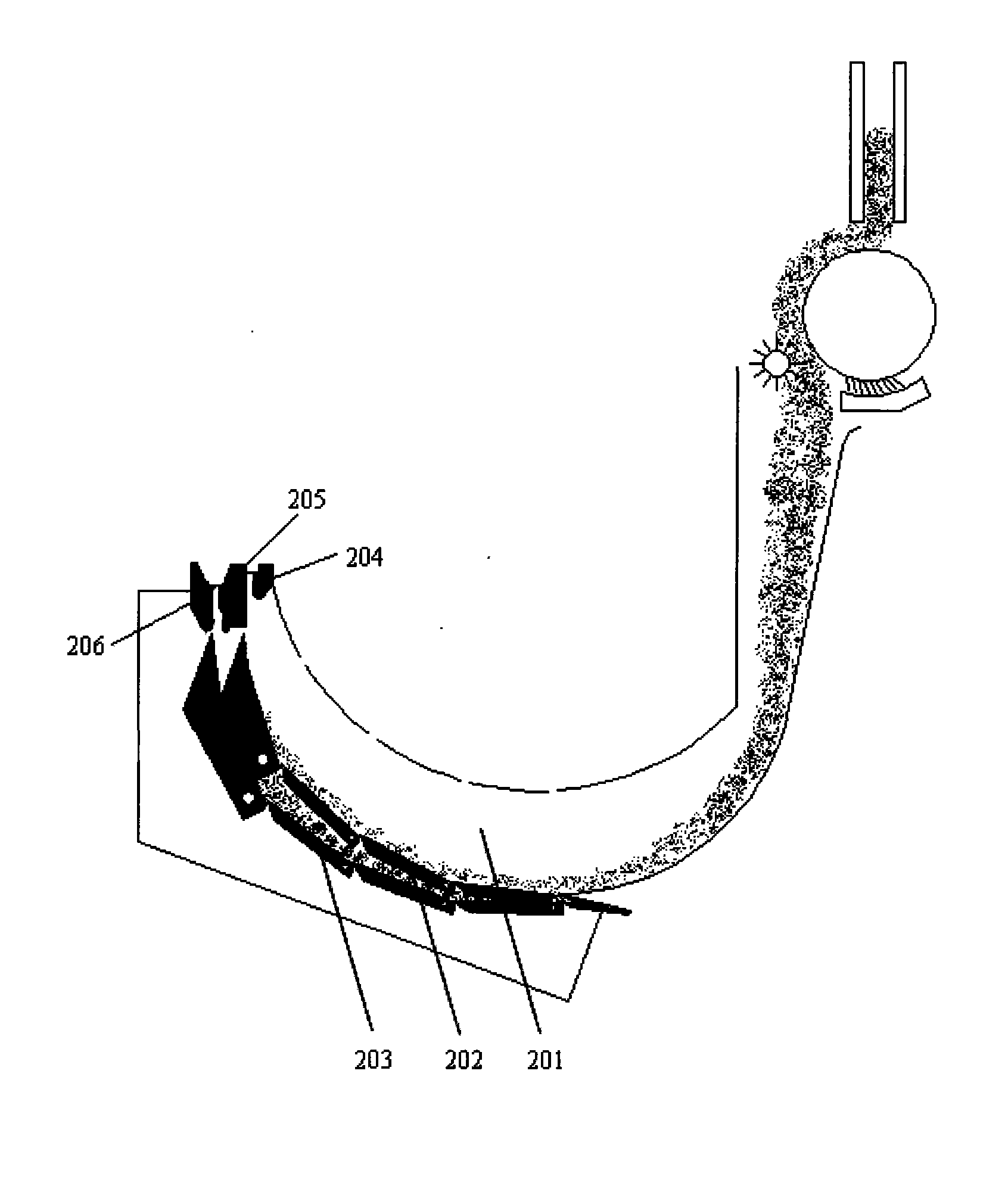

[0019] The method of the present invention is realized by the shredded tobacco pneumatic conveying method, and the shredded tobacco is input into an air groove with an upwardly inclined nozzle that can be rotatably adjusted to form a continuous shredded tobacco flow. The specific implementation method is:

[0020] The shredded tobacco enters an air groove inclined upward along the acceleration direction, and the slope of the air groove increases gradually along the acceleration direction of the shredded tobacco, so that the shredded tobacco can be lifted;

[0021] The bottom of the air groove is designed and made into a plurality of corrugated bottom plates arranged in continuous arrangement. The right side of the bottom plate is provided with a nozzle, and the air flow is ejected from the nozzle opening along the acceleration direction of the shredded tobacco. At the nozzle mouth, the air flow meets the shredded tobacco flow. , to accelerate the tobacco flow;

[0022] Each c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com