Surface decoration method of ceramic artwork

A technology for ceramic handicrafts and surface decoration, which is applied in decorative arts and processes for producing decorative surface effects. colorful effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment, the present invention will be further described:

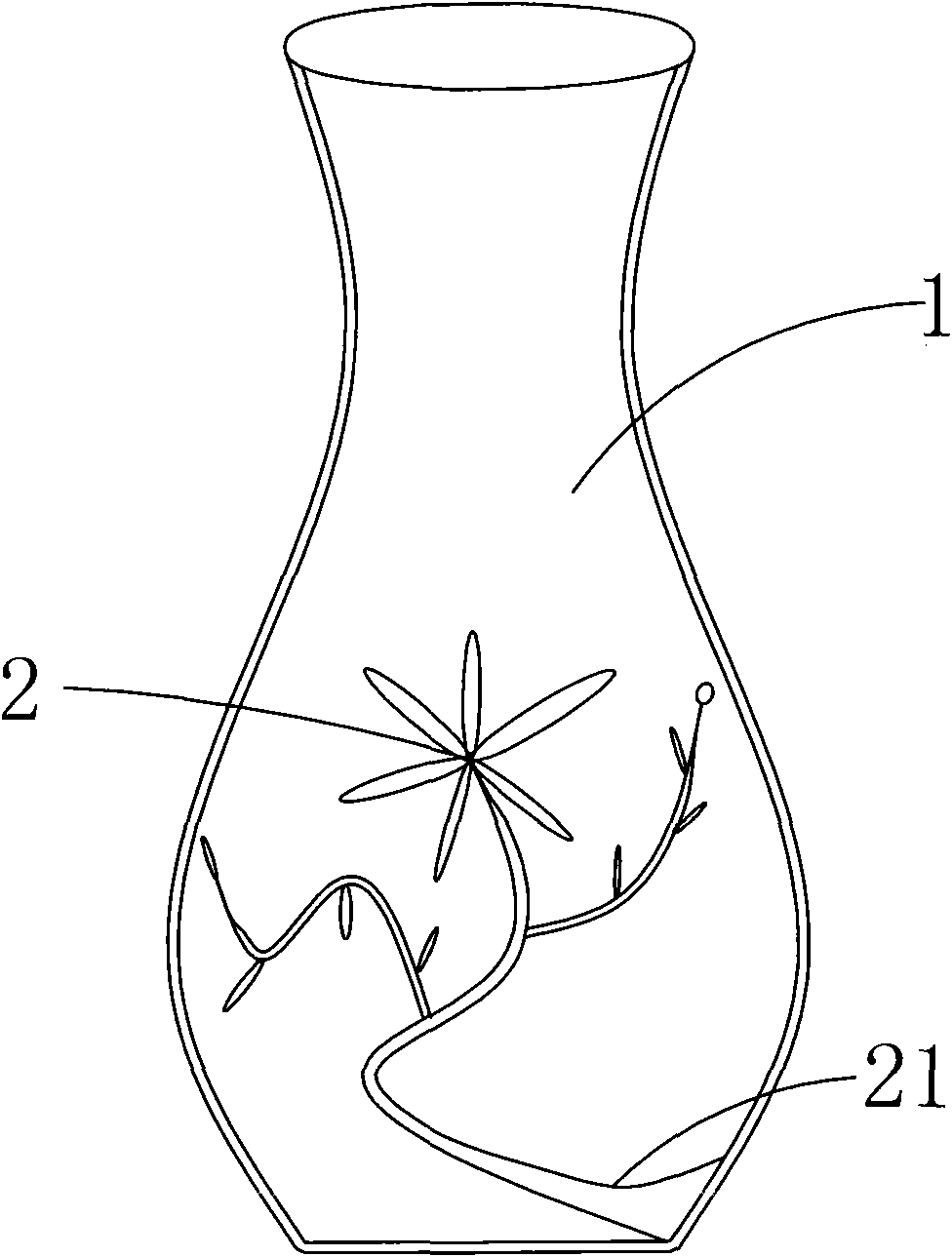

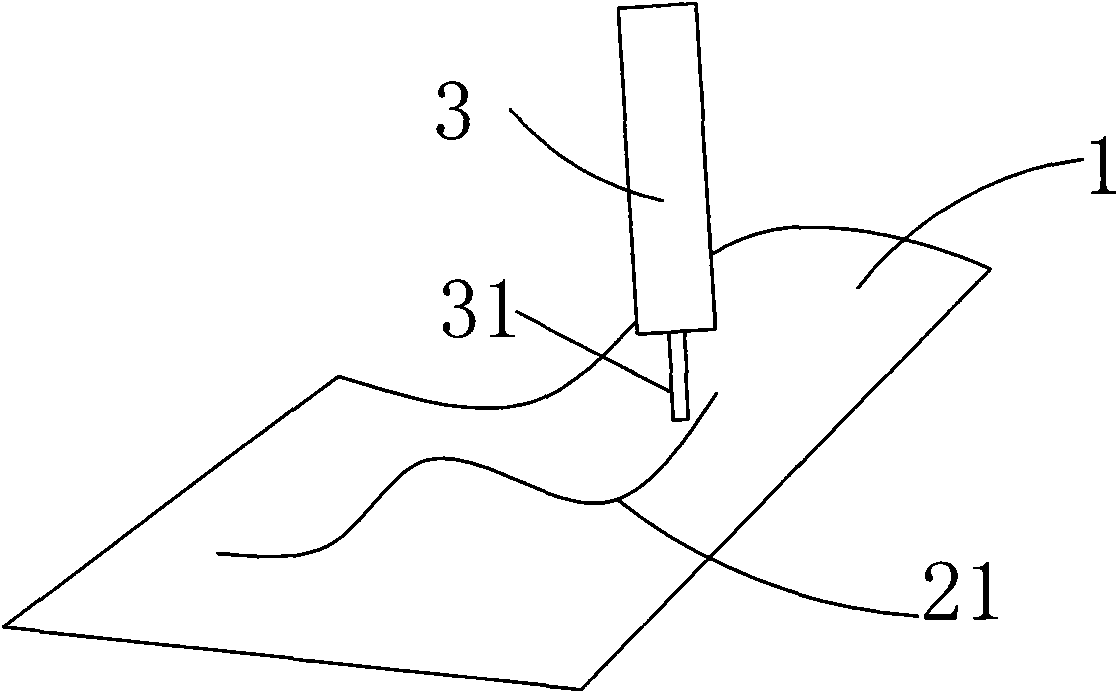

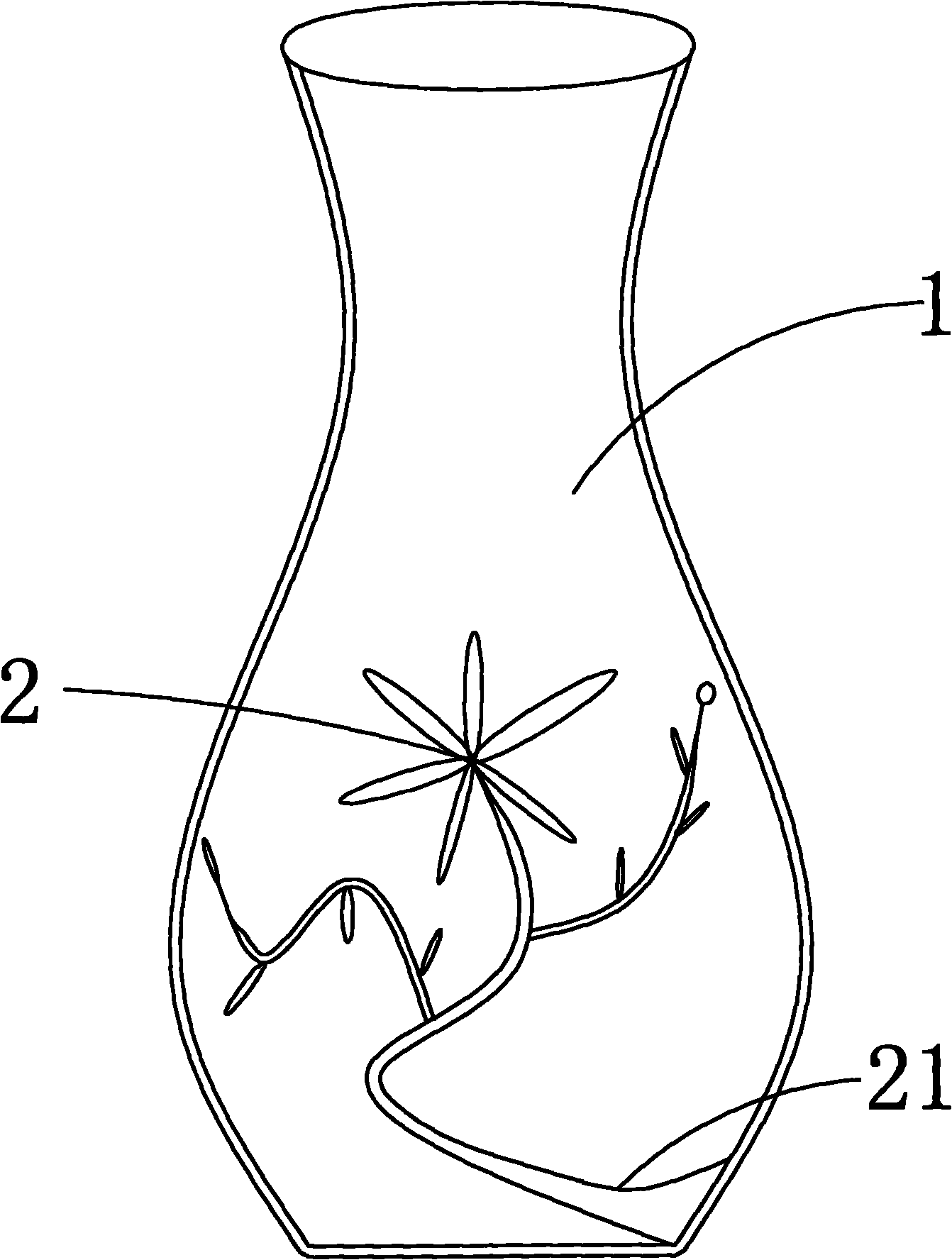

[0014] Such as figure 1 , 2 As shown, according to the production needs, the ceramic body (1) is made by the traditional method (the ceramic body can be bisque fired or not) and then the designed artwork (2) is hand-painted (or printed) on the ceramic body The surface of (1); fill in the thread stacking tool that injection needle (31) and plastic bottle (3) are made with mud material, the mud material in the plastic bottle (3) is extruded by hand, and mud material is with injection The needle (31) piles up three-dimensional lines along the artwork (2) on the surface of the ceramic body (1), and the three-dimensional lines constitute the outline (21) in the design artwork, and then bisque-fired for 750-800 hours after 3 to 4 hours. ℃, the three-dimensional lines of the mud material stacked on the surface of the ceramic body (1) are firmly combined with the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap