Special fertilizer production method and special equipment thereof

A special fertilizer and production method technology, applied in the preparation, application and application of organic fertilizers, can solve the problems of large process dust, serious environmental pollution, waste of resources, etc., achieve obvious biological fertilizer effect, avoid dust pollution, improve The effect of the work environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

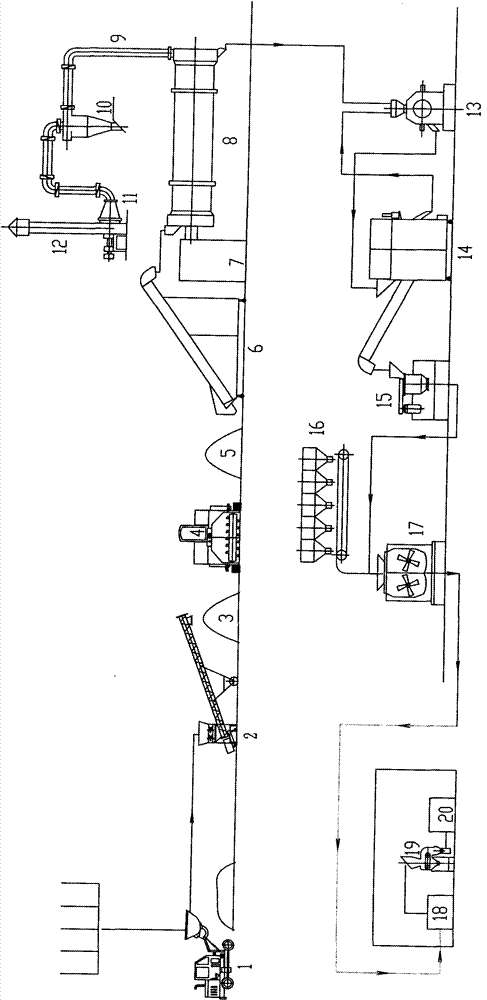

[0058] The special fertilizer production method of the present invention comprises the following technological process:

[0059] Step 1. Mix

[0060] The raw materials for preparing the fertilizer are added into the mixer according to the ratio (set carbon-nitrogen ratio) for mixing to prepare a mixed material, and the water content of the mixed material is controlled at 60%-65%. The raw materials include livestock and poultry manure, straw, chaff, edible fungus residue, organic waste from food factories and fungus strains, and the proportion thereof is determined according to the ingredients of the raw materials.

[0061] Step 2. Stir

[0062] Add the mixture prepared in step 1 into the mixer and mix well.

[0063] Step 3. Stretch fermentation

[0064] Stack the mixed material evenly stirred in step 2 into stacks, and carry out stack-type fermentation.

[0065] Step 4, flipping

[0066] Use a turning and throwing machine to turn and throw the piles fermented in step 3 to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com